Fibrous chemical energy storage power supply and preparation method thereof

An energy storage power source and fiber technology, which is applied in the manufacture of secondary batteries, circuits, electrical components, etc., can solve problems such as limitations, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Structure and preparation method of fiber chemical energy storage power source based on zinc-manganese battery of the present invention

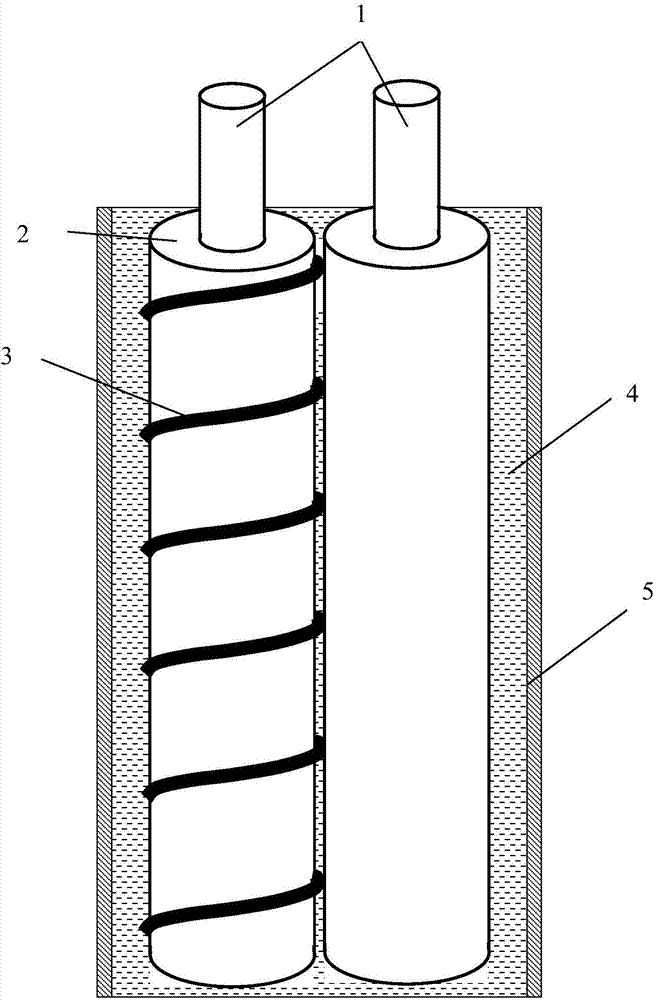

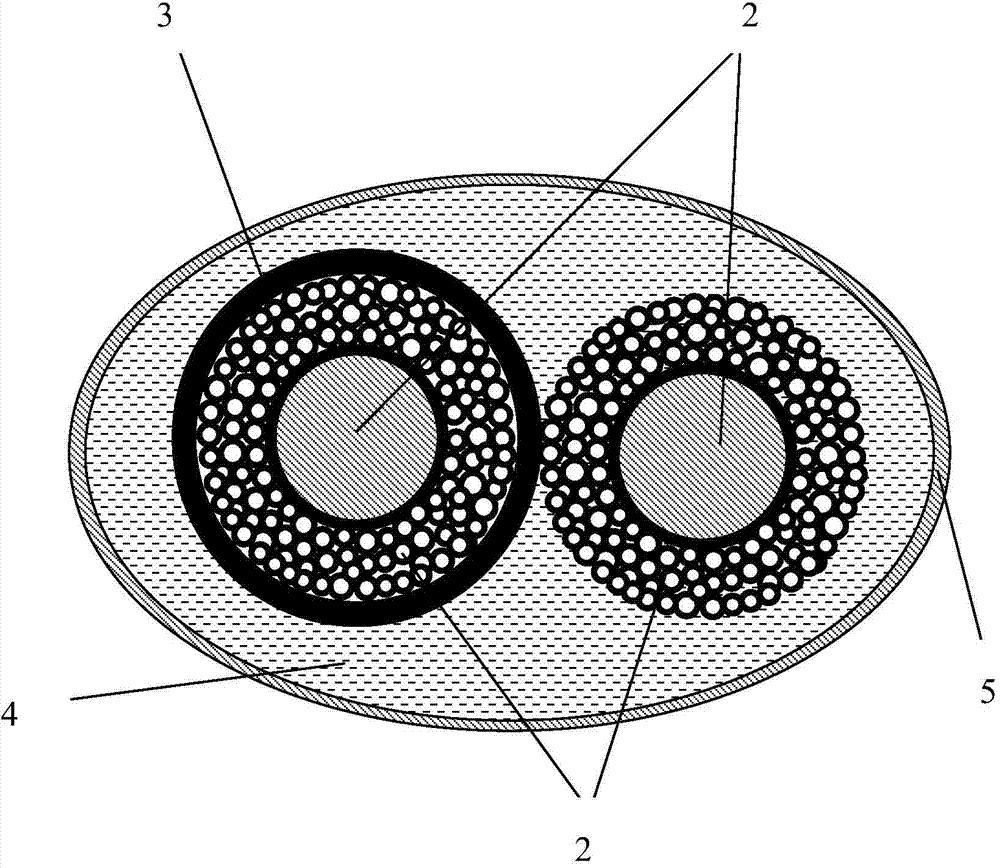

[0046] Such as figure 1 with figure 2 As shown, the fiber chemical energy storage power supply includes a conductive filament substrate 1, an electrochemically active material 2, a diaphragm fiber 3, an electrolyte 4 and an outer tube 5. The electrochemically active material 2 is generally a porous active material film structure, and the active material film is attached to the outer surface of the conductive filament substrate 1. The insulating diaphragm fiber 3 is evenly wound on the outer surface of the electrochemically active material 2. The conductive filament substrate 1, the electrochemically active material 2 and the diaphragm fiber 3 together constitute the main body of the fiber chemical energy storage power source. After the main body of the device is inserted into the outer sleeve 5, the outer sleeve 5 is filled with electr...

Embodiment 2

[0050] Structure and preparation method of fiber chemical energy storage power source based on nickel-zinc battery of the present invention

[0051] This embodiment is based on a fibrous chemical energy storage power supply for nickel-zinc batteries, using graphene fibers as the conductive filamentary substrate, graphene fibers coated with nickel hydroxide film as the fiber positive electrode; graphene fibers coated with the metal zinc film as fibers Negative electrode: The insulating enameled wire is used as a separator fiber to be evenly wound on the surface of the fiber positive electrode. Three fiber negative electrodes are placed in parallel with one fiber positive electrode. The electrolyte is filled between the fiber positive electrode and the fiber negative electrode, and is coated with the flexible In the PTFE tube.

[0052] The method for preparing the positive electrode of the fiber chemical energy storage power source based on nickel-zinc battery is: multiple coating an...

Embodiment 3

[0054] Structure and preparation method of fiber chemical energy storage power supply based on lithium ion battery of the present invention

[0055] This embodiment is based on a fibrous chemical energy storage power source of a lithium ion battery, and a stainless steel wire is used as a conductive wire substrate, and LiCoO is coated. 2 The stainless steel wire of the film is the fiber positive electrode; Li is coated 4 Ti 5 O 12 The stainless steel wire of the film is the fiber negative electrode; the insulating enameled wire is used as the diaphragm fiber to be evenly wound on the surface of the fiber positive electrode. The fiber negative electrode and the fiber positive electrode are placed parallel to each other. The electrolyte is filled between the fiber positive electrode and the fiber negative electrode, and is coated with it. Covered in a flexible PTFE tube.

[0056] The method for preparing the positive electrode of the fiber chemical energy storage power source based on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com