Preparation method for titanium dioxide (B)-graphene self-winding nano composite material

A nanocomposite material, titanium dioxide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex operation of titanium dioxide nanotube powder, unbearable charge and discharge, and increased production cost, etc. Achieve excellent structural stability and electrical conductivity, good electrochemical performance, and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

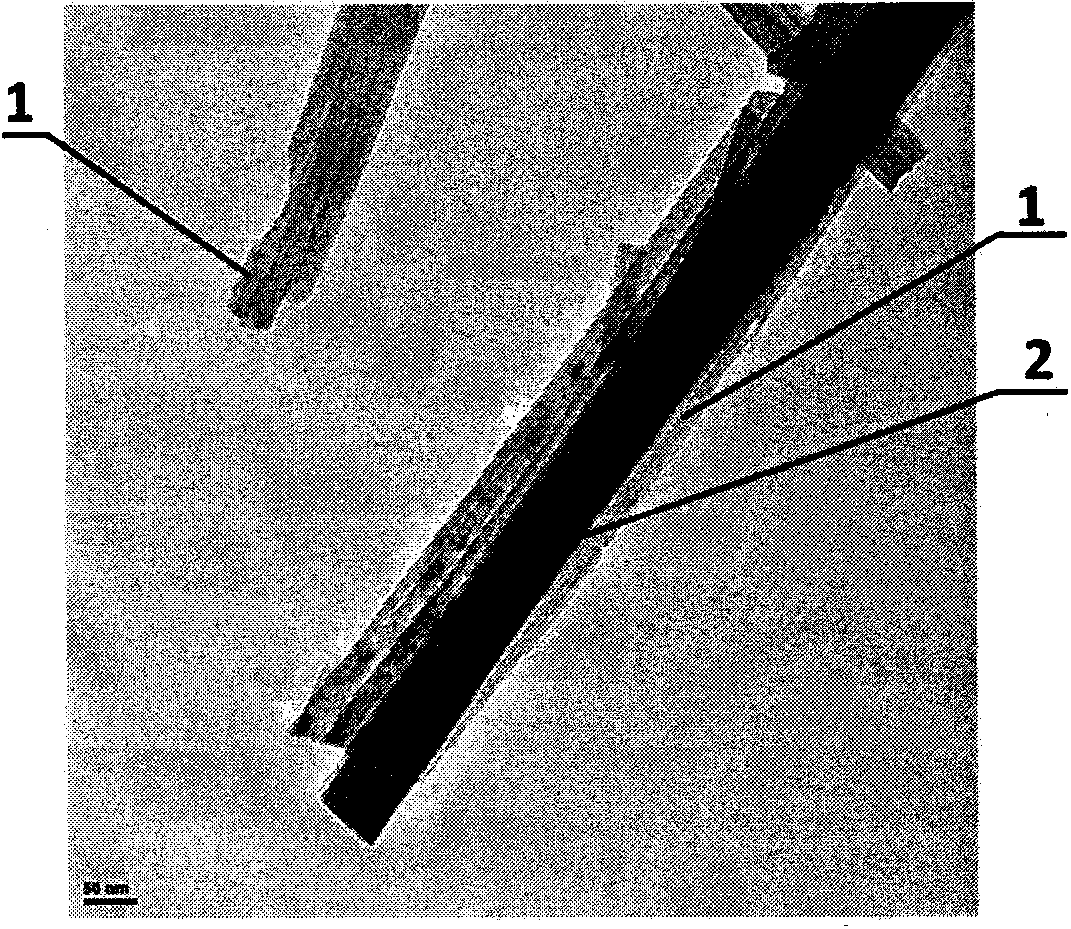

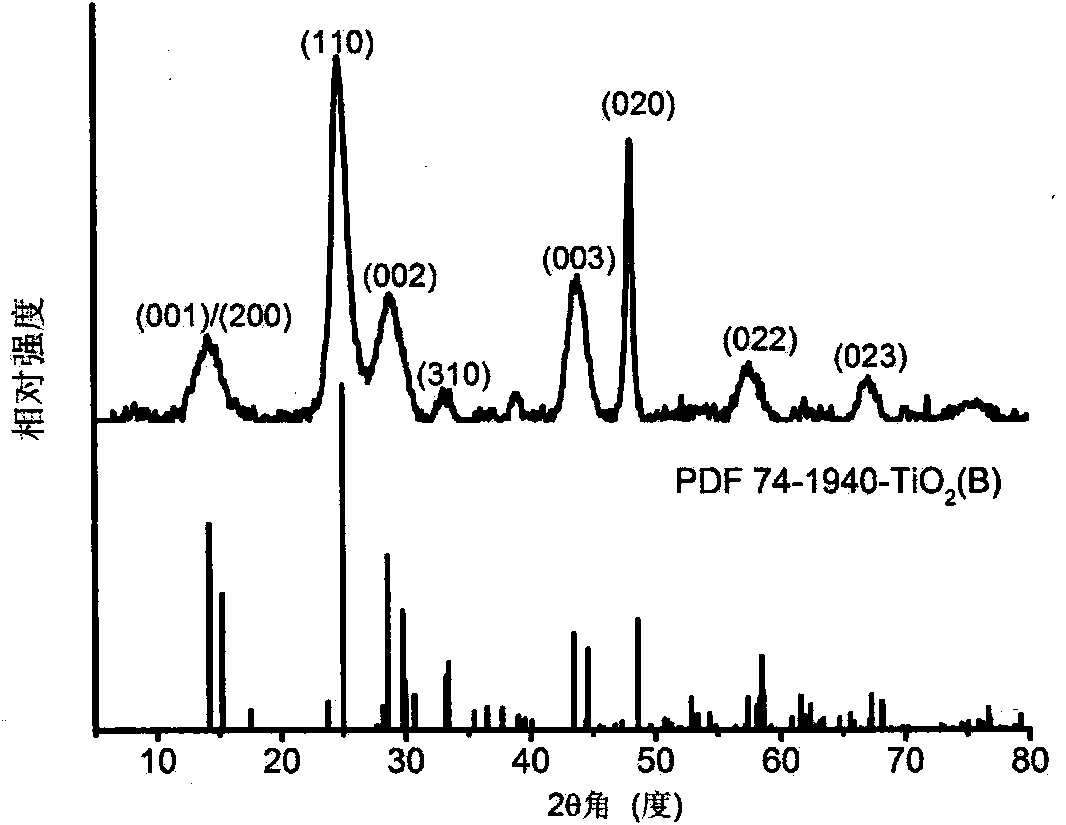

Image

Examples

Embodiment 1

[0025] The specific steps of a preparation method of titanium dioxide (B)-graphene self-winding nanocomposite material are as follows:

[0026] (1) carry out hydrothermal reaction

[0027] Taking commercially available titanium dioxide powder and graphene oxide solution as raw materials, according to the mass (g) of titanium dioxide powder: the volume (mL) of graphene oxide solution: the ratio of the volume (mL) of sodium hydroxide solution is 1: 20: 250 Ratio, the concentration of the graphene oxide solution is 10 mg / mL, and the concentration of the sodium hydroxide solution is 10 mol / L. First, titanium dioxide powder was added into the graphene oxide solution, and stirred for 4 hours to prepare a uniform dispersion of titanium dioxide. Add the sodium hydroxide solution into the dispersion, and stir for another 30 minutes to prepare a uniform mixed solution of titanium dioxide-graphene oxide-sodium hydroxide, and then place the mixed solution in the reaction kettle, A hydro...

Embodiment 2

[0031] The specific steps of a preparation method of titanium dioxide (B)-graphene self-winding nanocomposite material are as follows:

[0032] With embodiment 1, wherein:

[0033] In the (1) step, the mass (g) of titanium dioxide powder: the volume (mL) of graphene oxide solution: the ratio of the volume (mL) of sodium hydroxide solution is 1: 10: 80, and described graphene oxide solution The concentration is 2 mg / mL, and the concentration of the sodium hydroxide solution is 6 mol / L. Add the titanium dioxide powder raw material into the graphene oxide solution, stir for 2 hours to prepare a uniform dispersion of titanium dioxide, then add sodium hydroxide solution to the dispersion, and stir for another 10 minutes to form titanium dioxide-graphite oxide A homogeneous mixture of ene-sodium hydroxide, the hydrothermal reaction temperature is 120°C, and the reaction time is 24 hours;

[0034] In the 2nd step, the thick thing that the 1st step makes: the ratio of the volume (mL) ...

Embodiment 3

[0036] The specific steps of a preparation method of titanium dioxide (B)-graphene self-winding nanocomposite material are as follows:

[0037] With embodiment 1, wherein:

[0038] In the (1) step, the mass (g) of titanium dioxide powder: the volume (mL) of graphene oxide solution: the ratio of the volume (mL) of sodium hydroxide solution is 1: 50: 400, and described graphene oxide solution The concentration is 20 mg / mL, and the concentration of the sodium hydroxide solution is 15 mol / L. Add the titanium dioxide powder raw material into the graphene oxide solution, stir for 6 hours to prepare a uniform dispersion of titanium dioxide, then add sodium hydroxide solution to the dispersion, and stir for another 60 minutes to form titanium dioxide-graphite oxide A homogeneous mixture of ene-sodium hydroxide, the hydrothermal reaction temperature is 180°C, and the reaction time is 96 hours;

[0039] In the (2) step, the thick thing that (1) step makes: the ratio of the volume (mL)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com