Amino hybrid SiO2 aerogel material and application thereof

A technology of airgel and amino, which is used in the development of new materials and new applications, can solve the problems of high adsorption and desorption temperature, low adsorption capacity, low cycle absorption efficiency, etc., and achieve reduced operation steps and high adsorption selectivity High, easy industrial production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] At 0°C, tetraethyl orthosilicate, absolute ethanol, deionized water and 3-aminopropyltriethoxysilane were stirred and mixed evenly, and then left to stand to obtain amino hybrid SiO 2 Wet gel, the wet gel continued to age at 20°C for 24 hours, during the aging period, the wet gel was solvent-substituted 6 times with absolute ethanol to obtain an alcohol gel, and the alcohol gel was subjected to CO at 50°C and 10MPa 2 Amino-hybrid SiO obtained by supercritical drying for 4 hours 2 Airgel, in which tetraethylorthosilicate: 3-aminopropyltriethoxysilane=1:4, (tetraethylorthosilicate+3-aminopropyltriethoxysilane): absolute ethanol : deionized water = 1:3:3. Amino hybrid SiO 2 The density of airgel is 0.11g / cm 3 , the specific surface area is 118m 2 / g, CO at 20 and 50°C 2 The adsorption capacity was 4.5 and 3.8 mmol / g.

[0021] See attached picture, figure 1 Amino hybrid SiO made for Example 1 2 A sample photo of the airgel.

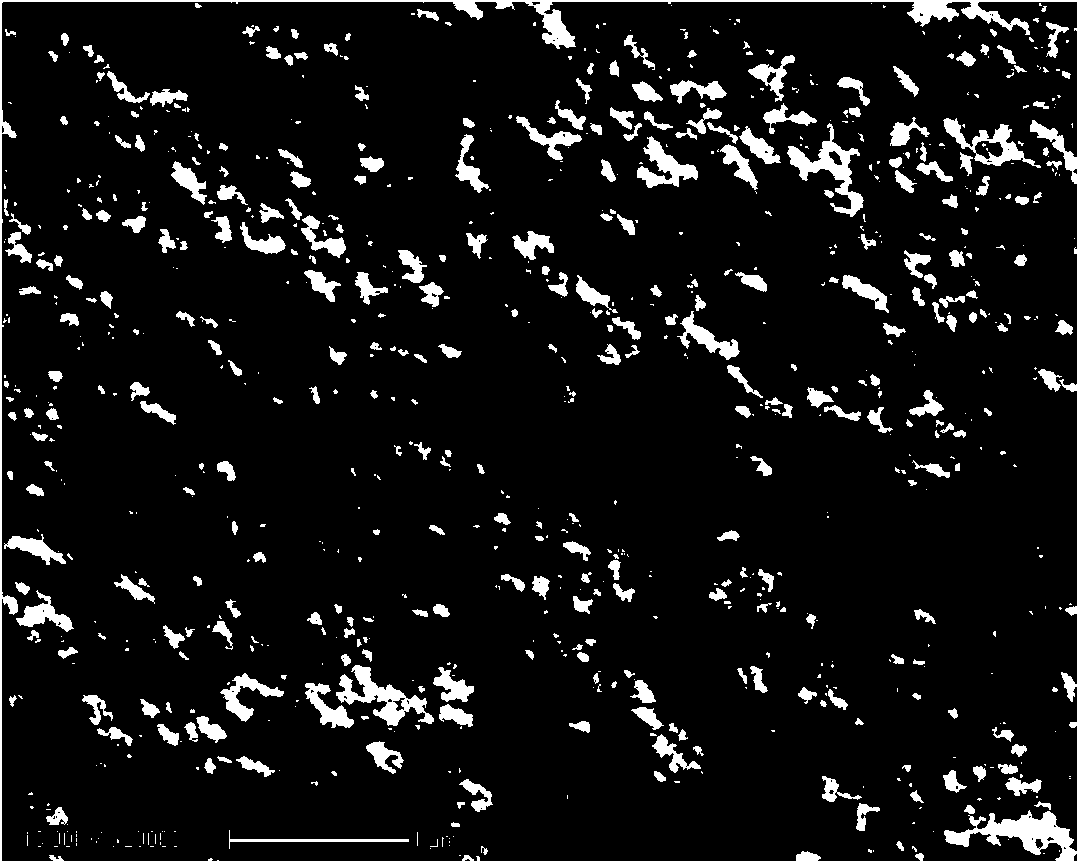

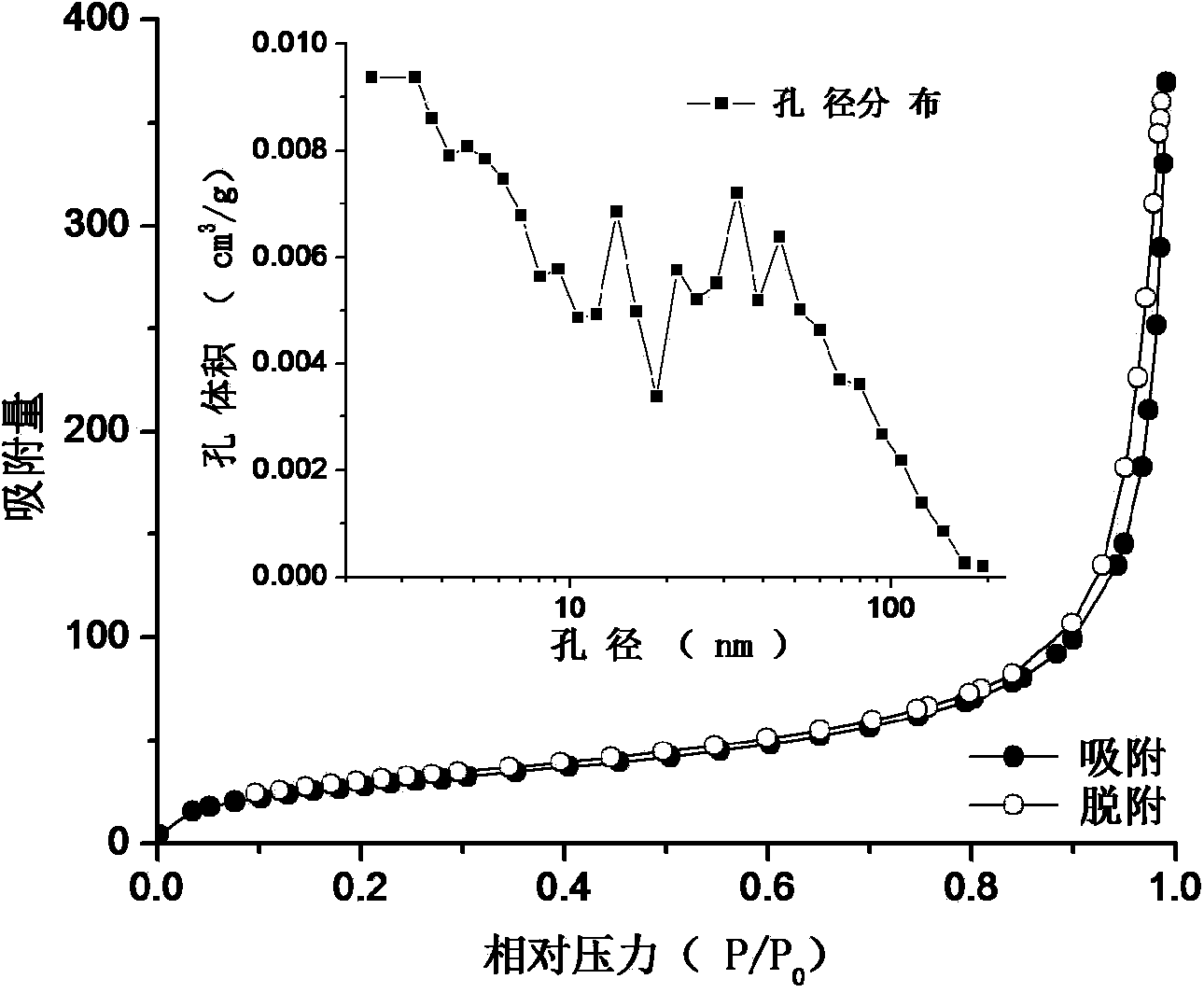

[0022] See attached picture, figure 2...

example 2

[0025] At 10°C, tetraethyl orthosilicate, absolute ethanol, deionized water and 3-aminopropyltrimethoxysilane were stirred and mixed evenly, and then left to stand to obtain amino hybrid SiO 2 Wet gel, the wet gel continued to age at 30°C for 18 hours, during the aging period, the wet gel was solvent-substituted 5 times with absolute ethanol to obtain an alcohol gel, and the alcohol gel was subjected to CO at 40°C and 12MPa 2 Amino-hybrid SiO obtained by supercritical drying for 6 hours 2 Airgel, where tetramethyl orthosilicate: 3-aminopropyltrimethoxysilane=1:1, (tetramethyl orthosilicate + 3-aminopropyltrimethoxysilane): absolute ethanol: go Ionized water = 1:4:4. Amino hybrid SiO 2 The density of airgel is 0.10g / cm 3 , the specific surface area is 252m 2 / g, CO at 20 and 50°C 2 The adsorption capacity was 2.8 and 1.8 mmol / g.

example 3

[0027] At 20°C, tetraethyl orthosilicate, absolute ethanol, deionized water and 11-aminoundecyltriethoxysilane were stirred and mixed evenly, and then left to stand to obtain amino hybrid SiO 2 Wet gel, the wet gel was aged at 40°C for 12 hours, during the aging period, the wet gel was solvent-substituted 4 times with absolute ethanol to obtain the alcohol gel, and the alcohol gel was subjected to CO at 40°C, 8MPa 2 Amino-hybridized SiO was obtained by supercritical drying for 2 hours 2 Airgel, in which tetraethylorthosilicate: 11-aminoundecyltriethoxysilane=1:2, (tetraethylorthosilicate+11-aminoundecyltriethoxysilane) : absolute ethanol: deionized water = 1:2:3. Amino hybrid SiO 2 The density of airgel is 0.11g / cm 3 , the specific surface area is 162m 2 / g, CO at 20 and 50°C 2 The adsorption capacity was 3.2 and 2.7 mmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com