A kind of preparation method of cobalt metal organic framework/macroporous carbon composite

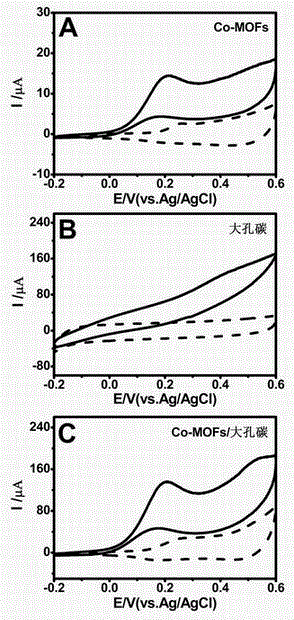

An organic framework and macroporous carbon technology, applied in organic compound/hydride/coordination complex catalysts, electrolytic organic production, chemical instruments and methods, etc., to achieve good stability, avoid agglomeration, and excellent electrocatalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation method of Co-MOFs / macroporous carbon composite material of the present invention comprises the following steps:

[0017] Step 1: Add 50mg of macroporous carbon into 20mL of deionized water, and ultrasonicate for 10 minutes (the power of the ultrasonic machine is 350W).

[0018] Step 2: 95.2mg of cobalt chloride, 30mg of 5-(4-pyridyl)tetrazole, 40mg of 1,3-bis(4-pyridyl)propane and 66mg of sodium azide were added to the macroporous carbon dispersion, and then Sonicate for 10 minutes to mix well.

[0019] Step 3: transfer the mixture dispersion to a hydrothermal reaction kettle, react at 160° C. for 72 hours, and then naturally cool to room temperature.

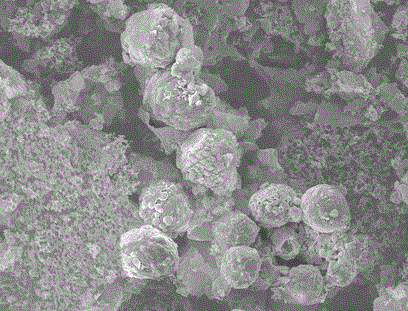

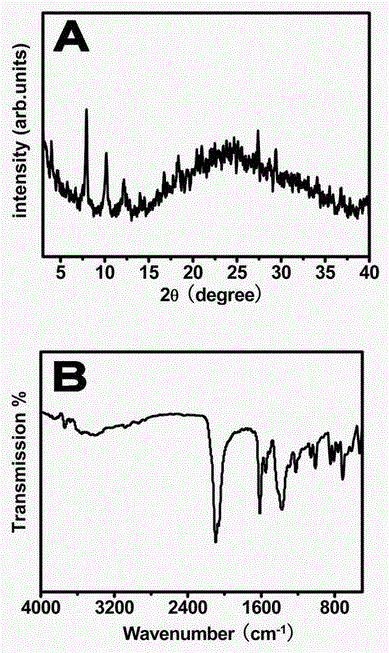

[0020] Step 4: After the obtained product was centrifuged at a high speed (8000 rpm), washed three times with deionized water, and then dried in vacuum at 50°C for 24 hours to obtain a Co-MOFs / macroporous carbon composite material. figure 1 It is the scanning electron microscope picture of the Co-MOFs / m...

Embodiment 2

[0022] The preparation method of Co-MOFs / macroporous carbon composite material of the present invention comprises the following steps:

[0023] Step 1: Add 20mg of macroporous carbon to 20mL of deionized water, and ultrasonicate for 10 minutes (the power of the ultrasonic machine is 350W).

[0024] Step 2: 95.2mg of cobalt chloride, 30mg of 5-(4-pyridyl)tetrazole, 40mg of 1,3-bis(4-pyridyl)propane and 66mg of sodium azide were added to the macroporous carbon dispersion, and then Sonicate for 10 minutes to mix well.

[0025] Step 3: transfer the mixture dispersion to a hydrothermal reaction kettle, react at 140° C. for 72 hours, and then naturally cool to room temperature.

[0026] Step 4: After the obtained product was centrifuged at a high speed (8000 rpm), washed three times with deionized water, and then dried in vacuum at 70°C for 24 hours to obtain a Co-MOFs / macroporous carbon composite material.

Embodiment 3

[0028] The preparation method of Co-MOFs / macroporous carbon composite material of the present invention comprises the following steps:

[0029] Step 1: Add 80mg of macroporous carbon into 20mL of deionized water, and ultrasonicate for 10 minutes (the power of the ultrasonic machine is 350W).

[0030] Step 2: 95.2mg of cobalt chloride, 30mg of 5-(4-pyridyl)tetrazole, 40mg of 1,3-bis(4-pyridyl)propane and 66mg of sodium azide were added to the macroporous carbon dispersion, and then Sonicate for 10 minutes to mix well.

[0031] Step 3: transfer the mixture dispersion to a hydrothermal reaction kettle, react at 150° C. for 70 hours, and then naturally cool to room temperature.

[0032] Step 4: After the obtained product was centrifuged at a high speed (8000 rpm), washed three times with deionized water, and then dried in vacuum at 60°C for 24 hours to obtain a Co-MOFs / macroporous carbon composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com