Negative electrode material and preparation method and application thereof

A negative electrode material and negative electrode sheet technology, which is applied in the field of negative electrode materials and its preparation, can solve problems such as safety failure, battery safety performance degradation, and low graphite crystallinity, so as to prevent heavy accumulation, improve safety performance, and solve safety performance and fast The effect of charging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The second aspect of the present invention is to provide the preparation method of the negative electrode material, comprising the following steps:

[0037] S1, acidifying or oxidizing the carbon nanomaterials;

[0038] S2, adding the carbon nanomaterial obtained in step S1 and the metal salt corresponding to the nano metal oxide into the solvent, and mixing into a uniform solution;

[0039]S3, performing the first heat treatment on the solution obtained in step S2 to obtain a precipitated powder, and performing a second heat treatment after filtering and washing to obtain a carbon nanocomposite material loaded with nano metal oxides;

[0040] S4. Fusing the precursor of the second carbon-based material, the first carbon-based material, and the carbon nanocomposite material loaded with nano-metal oxides to obtain a semi-finished product;

[0041] S5, carbonizing, crushing, screening, and demagnetizing the semi-finished product obtained in step S4 to obtain the negative...

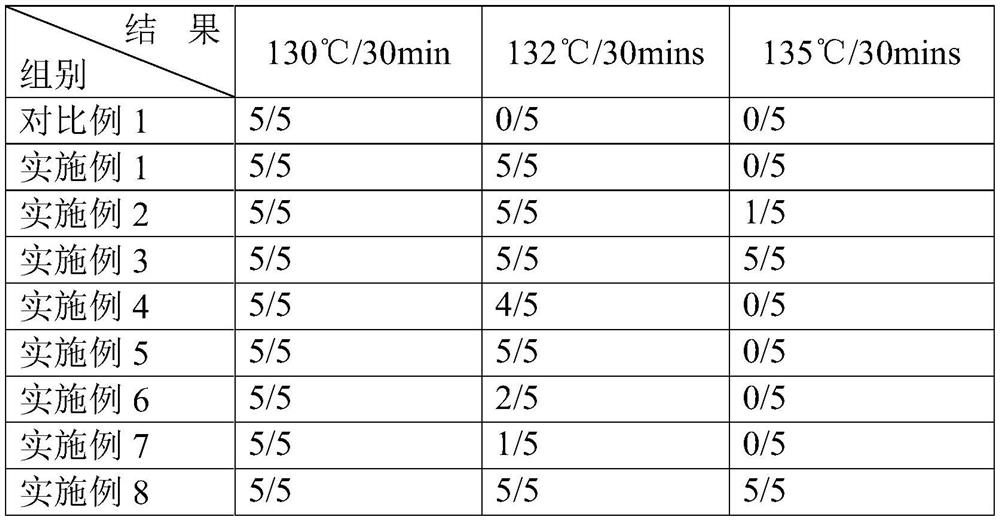

Embodiment 1

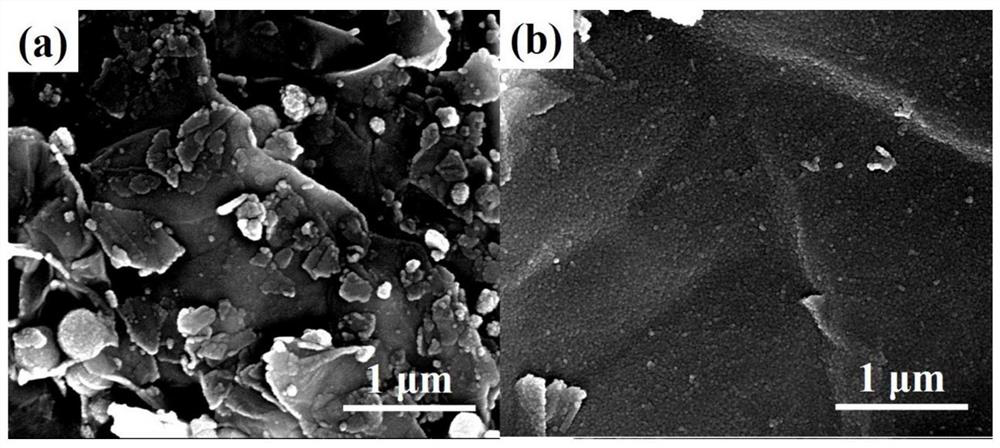

[0050] A negative electrode material, including graphite (Dv50=13 μm, purity greater than 99.8%) and a coating layer coated on the graphite surface; the coating layer includes pitch (softening point is about 120 ° C) and additives, the additives include Graphene and nanometer metal alumina loaded on the graphene.

[0051] The preparation method of this negative electrode material is:

[0052] 1) Add graphene oxide and aluminum nitrate (mass ratio 1:2) obtained through oxidation into ethanol, and fully mix to form a uniform solution;

[0053] 2) Add the solution into the reaction kettle, and perform solvothermal reduction at 200°C for 2 hours;

[0054] 3) Collect the sediment in the lower layer of the reaction kettle, filter, wash and dry, and then heat-treat it under an argon atmosphere at 450°C to obtain a graphene composite material loaded with metal alumina;

[0055] 4) Add graphite (Dv50=13um, purity greater than 99.8%), asphalt (softening point around 120°C) and graphen...

Embodiment 2

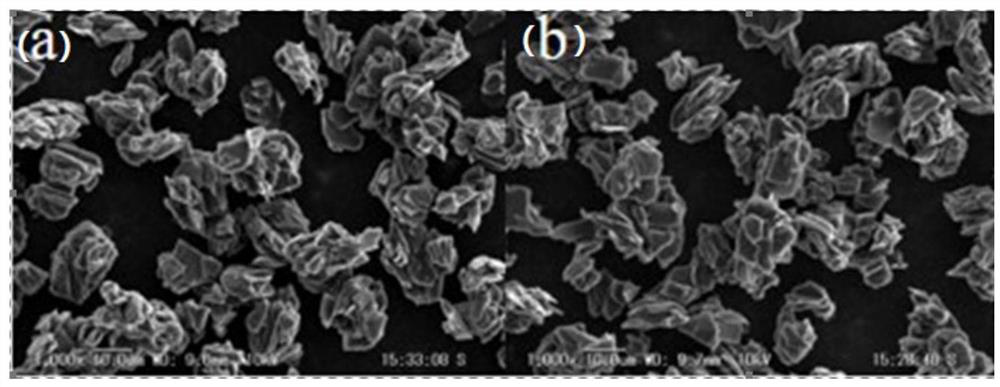

[0058] The difference from Example 1 is the setting of the cladding layer.

[0059] The coating layer includes pitch (the softening point is about 120°C) and additives, and the additives include carbon nanotubes and nanometer metal titanium oxide supported on the carbon nanotubes.

[0060] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com