Combined type method for extracting schisandrin b from fructus schisandrae

A technology of Schisandra chinensis B and Schisandra chinensis, applied in organic chemistry and other directions, can solve the problems of high extraction cost, long extraction time, large amount of solvent, etc., to improve the utilization rate, meet the needs of large-scale industrial production and excellent extraction effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

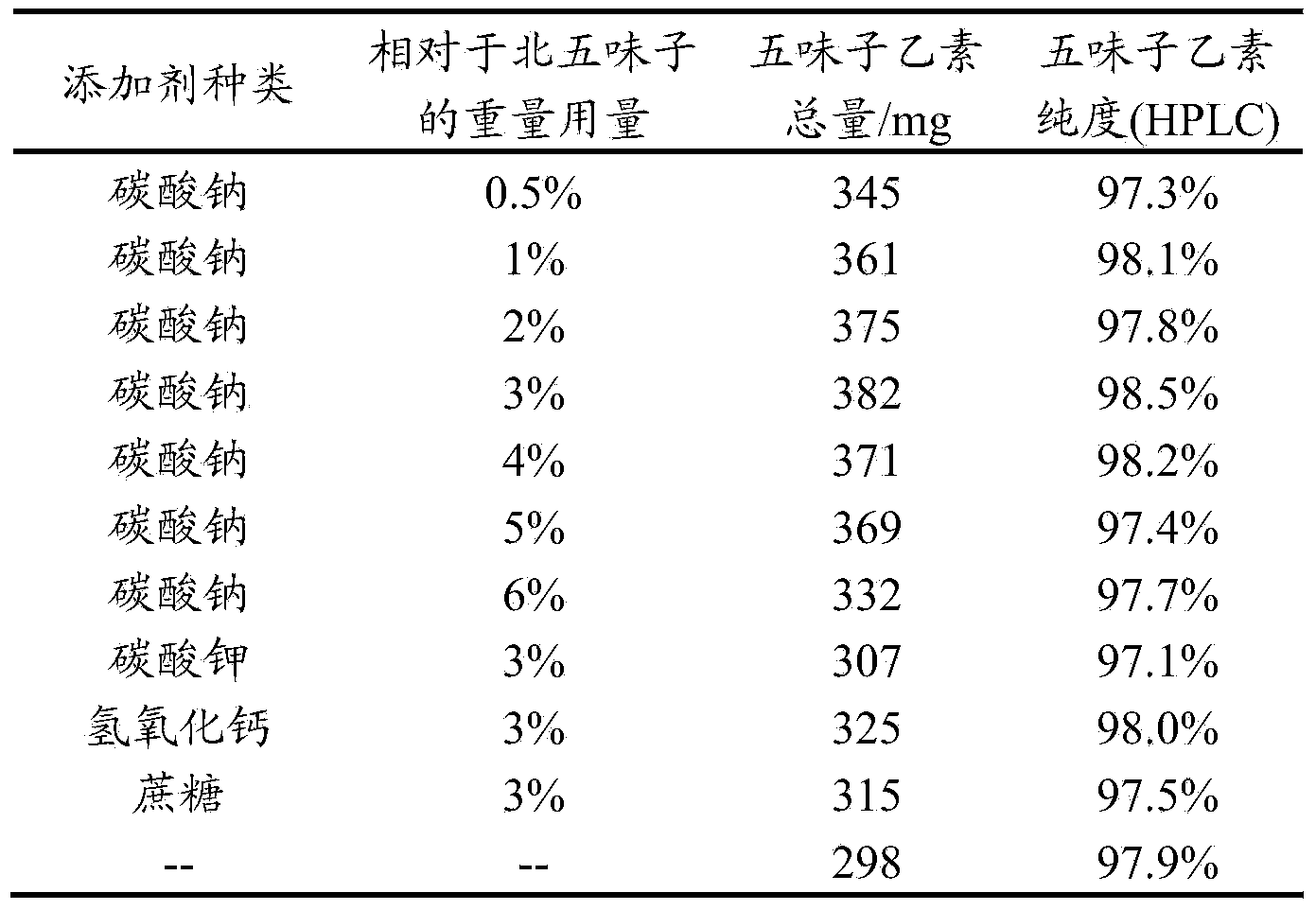

[0043] Embodiment 1: the kind and consumption of additive in step A

[0044] A. Raw material pretreatment

[0045] Take 1kg of dried Schisandra chinensis, wash with warm water at 55°C, then filter, dry, and then crush through a 50-mesh sieve, then add different types and amounts of additives to the sieved powder, stir well and mix evenly, and then vibrate Grinding mechanically for 5-10 minutes to obtain Schisandra powder. Wherein, the type and dosage of additives are shown in Table 1 below.

[0046] B, preparation of compound extractant

[0047] Stir and mix the ionic liquid 1-butyl-2,3-dimethylimidazolium chloride and the auxiliary agent diethylene glycol dimethyl ether according to a weight ratio of 1:3, and then add ten Hexaalkyltrimethylammonium bromide, continue to stir at room temperature for 20 minutes, and mix evenly to obtain the required composite extractant.

[0048] C. Extraction operation

[0049] Weigh the schisandra powder of 100g of step A, add 800g of the...

Embodiment 2

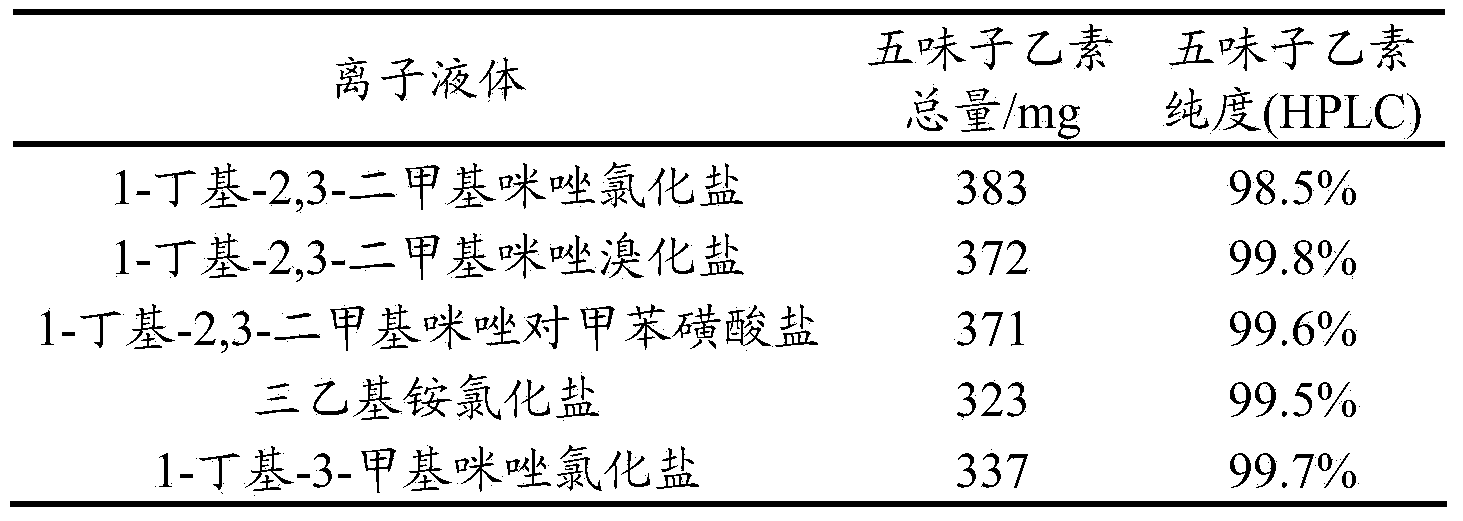

[0060] Embodiment 2: Extract the kind of ionic liquid in step B

[0061] A. Raw material pretreatment

[0062] Take 1kg of dried Schisandra chinensis, wash with warm water at 60°C, then filter, dry, and then crush through a 60-mesh sieve, then add 3% sodium carbonate solid of dry Schisandra chinensis weight to the sieved powder, stir well and mix evenly Finally, mechanically pulverize with a vibrating mill for 5-10 minutes to obtain Schisandra chinensis powder.

[0063] B, preparation of compound extractant

[0064] Stir and mix different types of ionic liquids and additives diethylene glycol dimethyl ether according to a weight ratio of 1:3, then add cetyltrimethylammonium bromide equivalent to 4% of the weight of the ionic liquid, and continue at room temperature Stir for 25 minutes and mix evenly to obtain the desired compound extractant. Wherein, the types of ionic liquids are shown in Table 2 below.

[0065] C. Extraction operation

[0066] Weigh the schisandra powde...

Embodiment 3

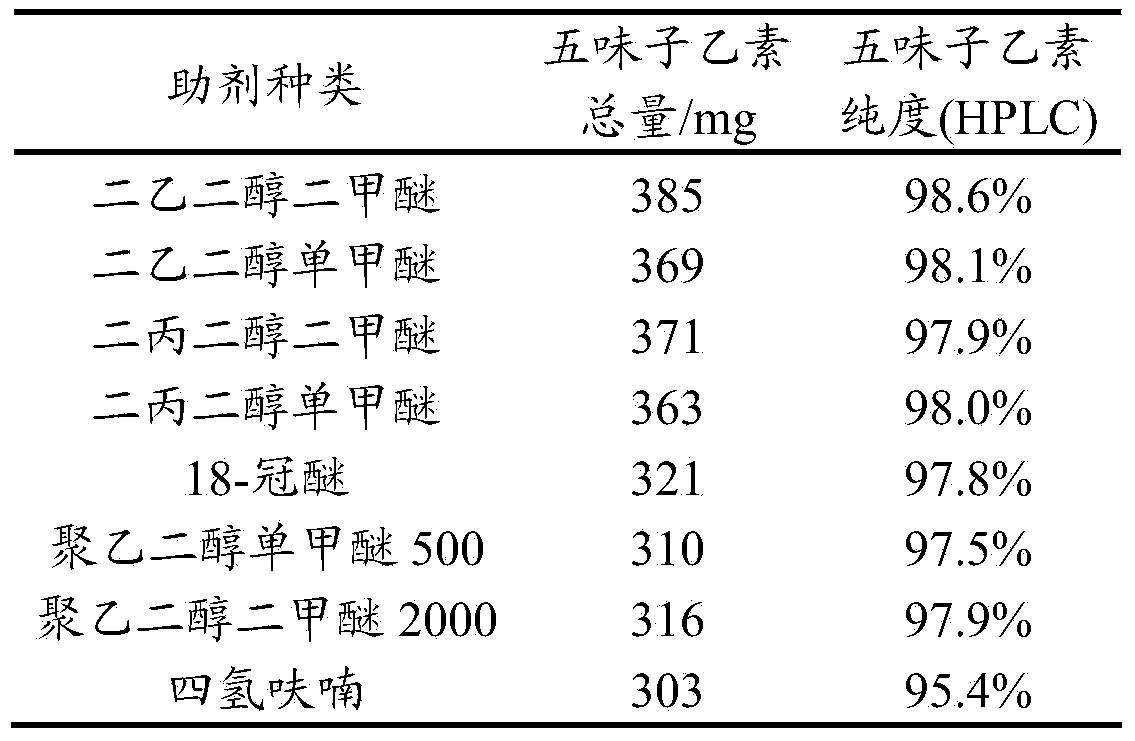

[0073] Embodiment 3: the kind of auxiliary agent

[0074] A. Raw material pretreatment

[0075] Take 1kg of dried Schisandra chinensis, wash at 50°C, then filter and dry, crush and pass through a 70-mesh sieve, then add 3% sodium carbonate solid of dry Schisandra chinensis weight to the sieved powder, stir well and mix evenly Finally, mechanically pulverize with a vibrating mill for 5-10 minutes to obtain Schisandra chinensis powder.

[0076] B, preparation of compound extractant

[0077] Stir and mix the ionic liquid 1-butyl-2,3-dimethylimidazolium chloride and the additive according to the weight ratio of 1:3, and then add hexadecyl trimethyl bromide equivalent to 4% by weight of the ionic liquid ammonium, continue to stir at room temperature for 20 minutes, and mix well to obtain the desired composite extractant. Wherein, the types of auxiliary agents are shown in Table 3 below.

[0078] C. Extraction operation

[0079] Weigh the schisandra powder of 100g of step A, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com