A kind of lignin-based polyoxyethylene ether and its preparation method and application

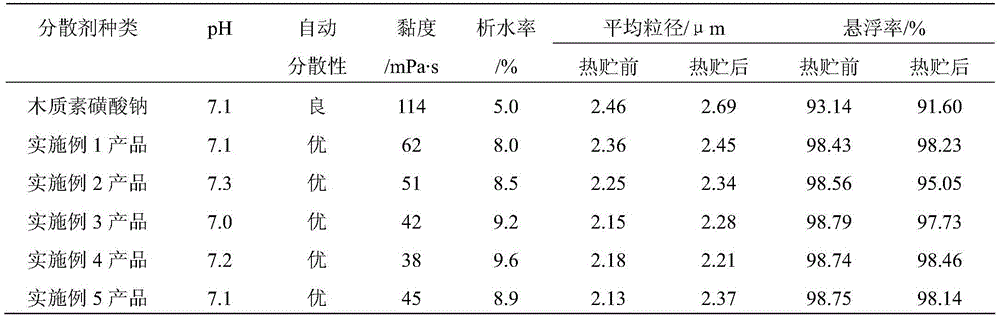

A technology based on polyoxyethylene ether and alkali lignin, which is applied in botany equipment and methods, applications, biocides, etc., can solve the problems of poor product dispersion and poor ability to inhibit the growth of original drug particle crystals, and achieve Excellent dispersion and viscosity reduction performance, rich variety and application range, less side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of lignin-based polyoxyethylene ether includes the following steps:

[0038] (1) Heat 200 grams of polyethylene glycol 400 to 40°C to melt, add 1 gram of antimony pentafluoride catalyst, stir and mix evenly, slowly add 10 grams of epichlorohydrin dropwise, and add dropwise within 30 minutes. After completion, react at 50°C for 1 hour to obtain modified polyethylene glycol 400 intermediate;

[0039] (2) Mix 100 grams of alkali pulping wood pulp black liquor with acid precipitation lignin (in weight percentage, solid content is 95%) with water to prepare a suspension with a mass percentage concentration of 30%, and add sodium hydroxide to adjust pH to 10.5, slowly add the modified polyethylene glycol 400 intermediate prepared in step (1) at 70°C, and the addition is completed within 1.5h. After the addition is complete, react at 80°C for 2h, and adjust after the reaction is complete pH to 7.0, cooling to room temperature to obtain lignin-based polyoxyethy...

Embodiment 2

[0041] A preparation method of lignin-based polyoxyethylene ether includes the following steps:

[0042] (1) Heat 100 grams of polyethylene glycol 2000 to 60°C to melt, add 3 grams of antimony pentachloride catalyst, stir and mix evenly, slowly add 15 grams of epichlorohydrin, dropwise within 60 minutes, and add dropwise After completion, react at 40°C for 2 hours to obtain modified polyethylene glycol 2000 intermediate;

[0043] (2) Mix 100 grams of alkali pulping bamboo pulp black liquor with acid precipitation lignin (in weight percentage, solid content is 95%) with water to prepare a suspension with a mass percentage concentration of 40%, and add sodium hydroxide to adjust pH to 10, slowly add the modified polyethylene glycol 2000 intermediate prepared in step (1) at 60°C. The addition is completed within 1h. After the addition is complete, react at 70°C for 4h, and adjust the pH after the reaction. To 6.0, cool to room temperature to obtain lignin-based polyoxyethylene ether ...

Embodiment 3

[0045] A preparation method of lignin-based polyoxyethylene ether includes the following steps:

[0046] (1) Heat 300 grams of polyethylene glycol 1000 to 50°C to melt, add 2 grams of boron trifluoride ether complex catalyst, stir and mix evenly, slowly add 30 grams of epichlorohydrin, and add dropwise within 50 minutes After the addition is complete, react at 60°C for 1.5 hours to obtain the modified polyethylene glycol 1000 intermediate;

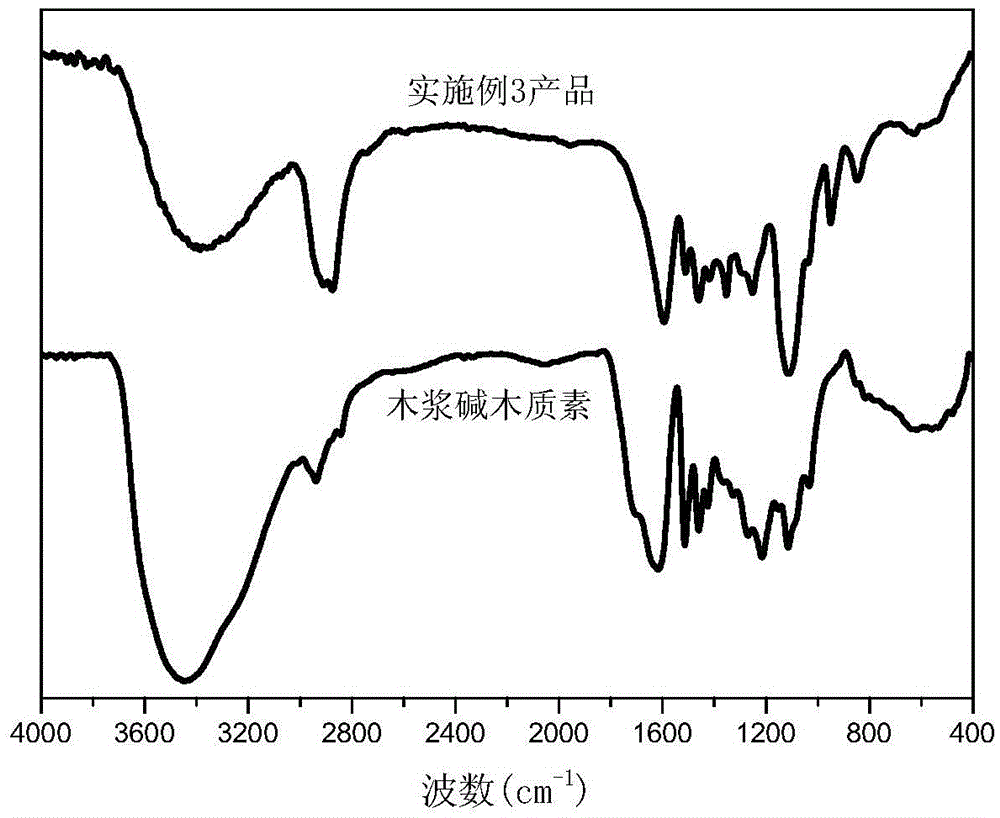

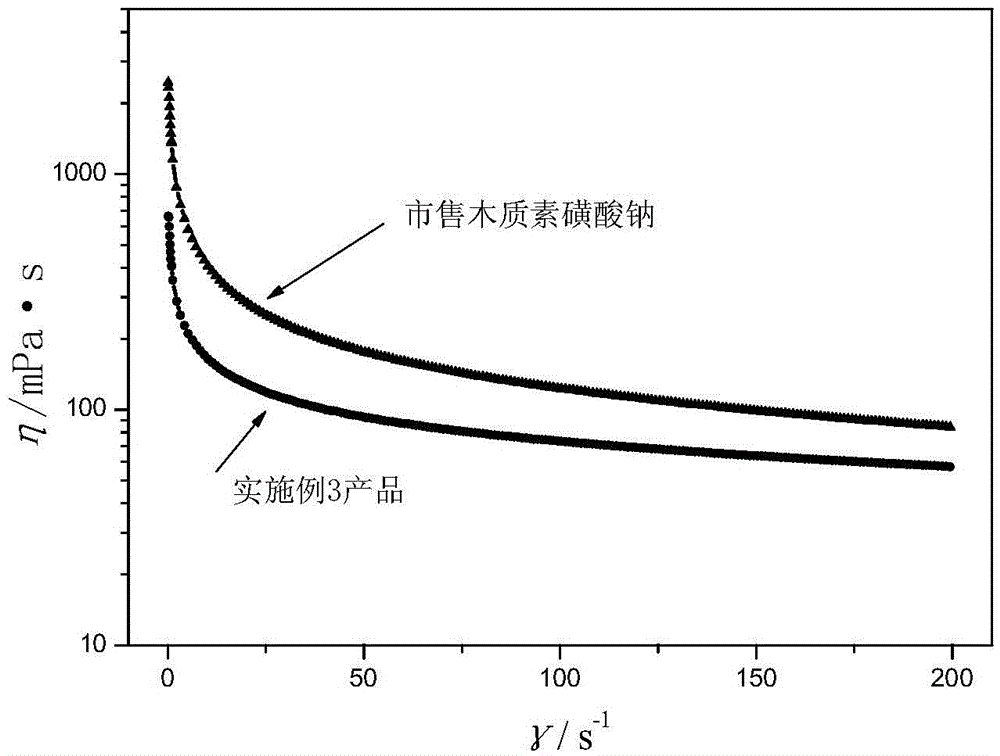

[0047] (2) Mix 100 grams of alkali pulping wood pulp black liquor with acid precipitation lignin (in weight percentage, solid content is 95%) with water to prepare a suspension with a mass percentage concentration of 35%, and add sodium hydroxide to adjust pH to 11, slowly add the modified polyethylene glycol 1000 intermediate prepared in step (1) at 80°C, dropwise addition is completed within 2h, after the dropwise addition, react at 75°C for 3h, adjust the pH after the reaction is complete After cooling to room temperature to 7.0, the lignin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com