A kind of production method of high molecular weight gamma-polyglutamic acid

A technology of polyglutamic acid and production method, which is applied in the field of biological fermentation to produce polymer materials, can solve the problems of unclear molecular weight range of γ-polyglutamic acid, difficult control of the molecular weight range of γ-polyglutamic acid, etc. High, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

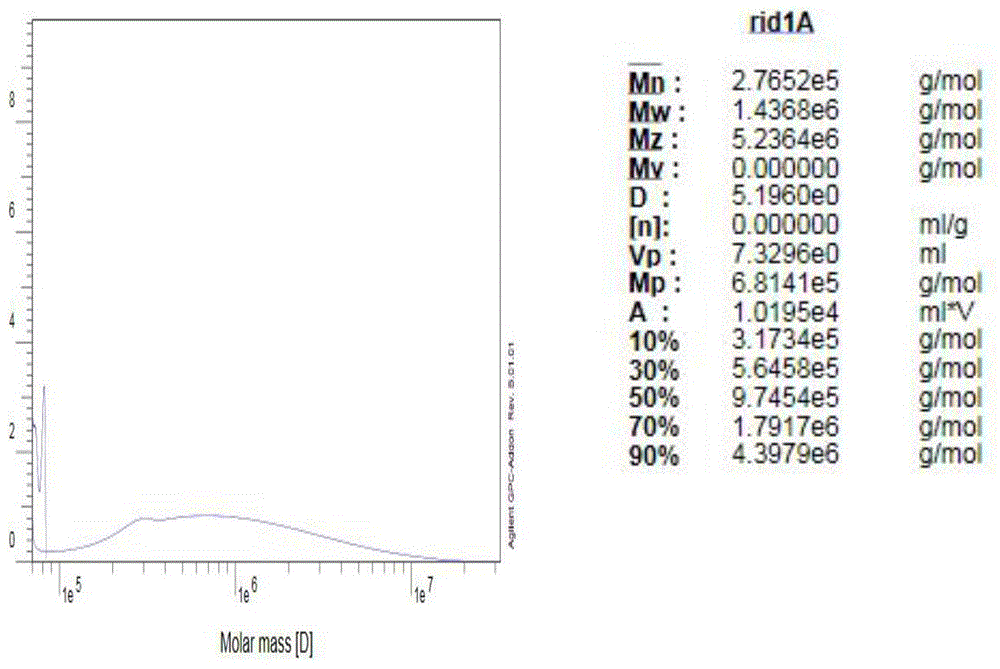

Embodiment 1

[0026] A production method of high molecular weight gamma-polyglutamic acid, comprising the steps of:

[0027] (1) Strain activation: the original strain of Bacillus licheniformis CGMCCNO.3336 was inoculated on the slant medium, cultured at 37°C for 16 hours, activated 2-3 times in this way, and mature slant seeds were prepared;

[0028] The slant medium consists of: peptone 10g / L, yeast powder 5g / L, NaCl10g / L, agar 20g / L, pH7.2, and the insufficient part is supplemented with pure water;

[0029] (2) Preparation of seed solution: inoculate one ring of activated slant seeds into a 500ml Erlenmeyer flask filled with 50ml of liquid medium, and culture at 37°C and 220rpm for 16 hours to logarithmic growth phase;

[0030] The seed medium consists of: glucose 30g / L, yeast extract 7g / L, tryptone 10g / L, K 2 HPO 4 0.5g / L, MgSO 4 ·7H 2 O0.5g / L, pH7.2, make up the insufficient part with pure water;

[0031](3) Fermentation in fermenter: inoculate the seed solution in step (2) with 1...

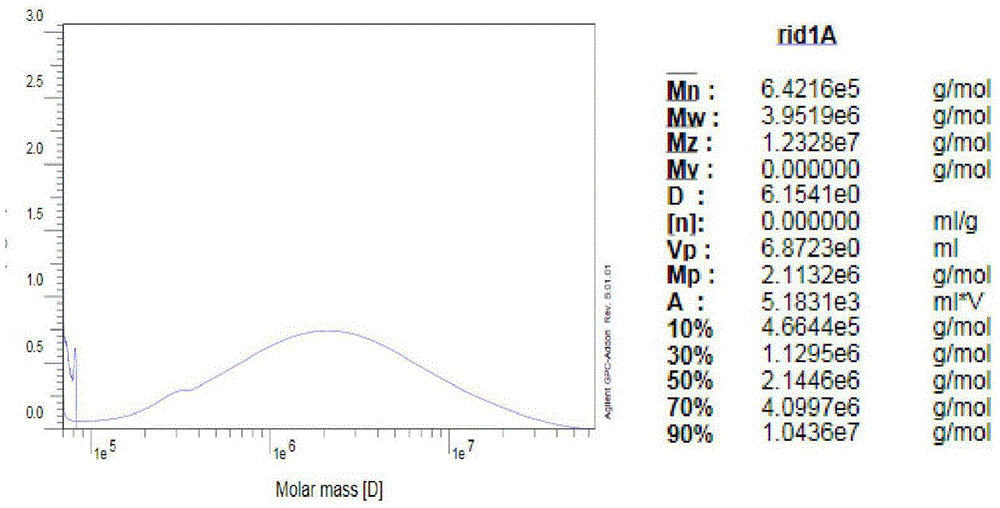

Embodiment 2

[0036] Strain activation and seed liquid preparation are the same as in Example 1

[0037] (3) Fermentation in fermenter: inoculate the seed solution in step (2) with 10% inoculum in the fermenter, the liquid volume of the fermentation medium in the 30L fermenter is 15L, the initial fermentation temperature is 39°C, and the tank pressure is 0.03Mpa for ventilation Volume 0.7vvm, speed 500rpm; when the fermentation broth OD 660 At 0.570, control the fermentation temperature to 32°C, adjust the rotation speed to 300rpm, and the ventilation rate to 1.8vvm, and start to add feed medium, control the pH at 7.4 to 4 hours before the end of fermentation, and the fermentation time is 72h.

[0038] The fermentation medium consists of: glucose 50g / L, yeast extract 20g / L, NH 4 NO 3 4.5g / L, MgSO 4 ·6H 2 O1.0g / L, NaCl10g / L, CaCl 2 ·6H 2 O1.2g / L, FeSO 4 0.009g / L, sodium glutamate 75g / L, pH value 7.4, make up the deficiency with purified water;

[0039] The fed-batch medium consists o...

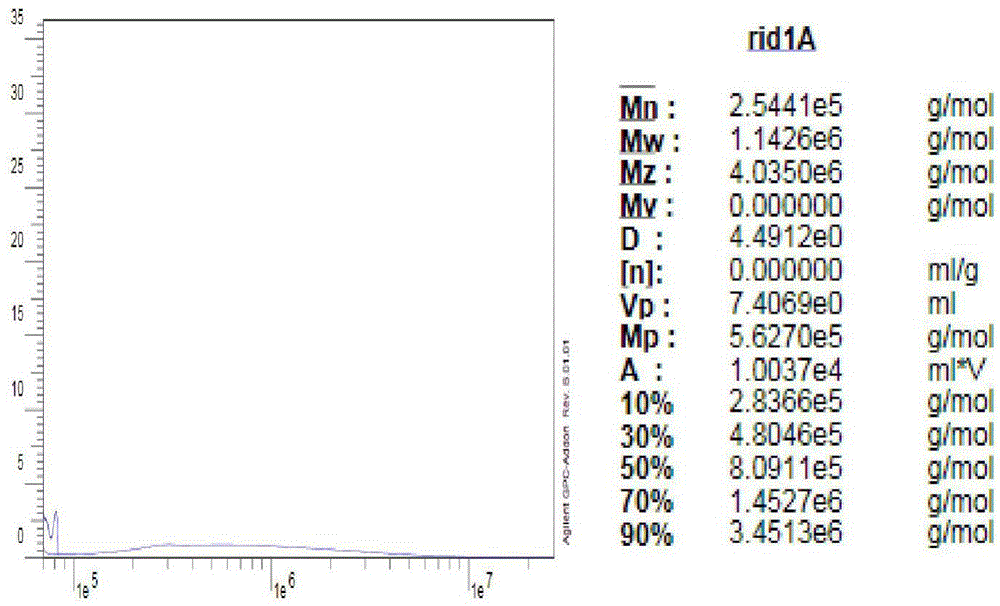

Embodiment 3

[0042] (3) Fermentation in fermenter: inoculate the seed solution in step (2) with 10% inoculum in the fermenter, the liquid volume of the fermentation medium in the 30L fermenter is 15L, the initial fermentation temperature is 40°C, and the tank pressure is 0.05Mpa for ventilation Volume 1.0vvm, speed 600rpm; when the fermentation broth OD 660 At 0.600, control the fermentation temperature to 35°C, adjust the rotation speed to 350rpm, and the ventilation rate to 2.0vvm, and start to add feeding medium, control the pH at 7.5 to 6 hours before the end of fermentation, and the fermentation time is 72h.

[0043] The fermentation medium consists of: glucose 60g / L, yeast extract 25g / L, NH 4 NO 3 5.5g / L, MgSO 4 ·6H 2 O1.2g / L, NaCl12g / L, CaCl 2 ·6H 2 O1.5g / L, FeSO 4 0.010g / L, sodium glutamate 80g / L, pH value 7.5, make up the deficiency with purified water;

[0044] The fed-batch medium consists of: glucose 850g / L, sodium chloride 60.0g / L, CaCl 2 ·6H 2 O15.0g / L, MnSO 4 10g / L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com