ZnO-based film and preparation method thereof

A thin film, zn1-xmxo technology, applied in the field of ZnO-based thin film and its preparation, can solve the problems of difficult to effectively control the morphology of ZnO-based nanomaterials, poor repeatability of ZnO-based nanomaterials, low electron mobility, etc., and achieve good response , easy operation, large specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

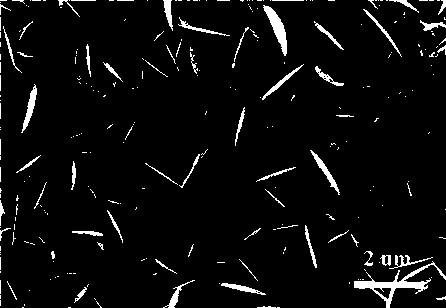

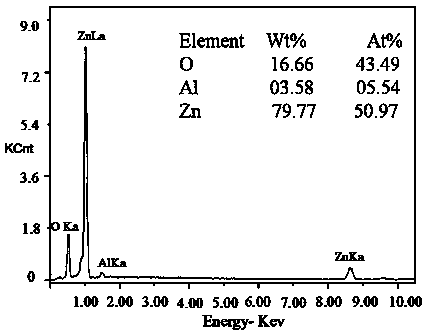

[0023] Example 1: Preparation of ZnO:Al film embedded with ZnO:Al nanosheets.

[0024] 1) ZnO, Al with a purity of 99.99% 2 o 3 Powder as raw material, according to Zn 0.96 Al 0.04 O stoichiometric ratio Zn:Al = 0.96:0.04 ratio, respectively weigh 30.00 g of ZnO powder, Al 2 o 3 Powder 0.7831 g. Pour the weighed powder into a ball mill jar equipped with agate balls and ethanol, and mill it on a ball mill for 72 hours to make the powder fine and evenly mixed. Then separate the raw material and dry it at 80°C for 24 hours, add a binder and grind it, and press it into a disc shape with a diameter of about 2 inches and a thickness of 3 mm. Put the shaped green body into a sintering furnace and sinter at 1200 °C for 12 hours to obtain the desired ceramic target.

[0025] 2) Using the magnetron sputtering method, using the ceramic target in step 1) as the target, deposit a layer of ZnO:Al thin film on the cleaned glass substrate, the deposition conditions are: the distance ...

example 2

[0029] Example 2: Preparation of ZnO:In thin films embedded with ZnO:In nanosheets.

[0030] 2) ZnO with a purity of 99.99%, In 2 o 3 Powder as raw material, according to Zn 0.98 In 0.02 O stoichiometric ratio Zn:In = 0.98:0.02 ratio, weigh 30.00 g of ZnO powder, In 2 o 3 Powder 1.0444g. Pour the weighed powder into a ball mill jar equipped with agate balls and ethanol, and mill it on a ball mill for 72 hours to make the powder fine and evenly mixed. Then separate the raw material and dry it at 80°C for 24 hours, add a binder and grind it, and press it into a disc shape with a diameter of about 2 inches and a thickness of 3 mm. Put the shaped green body into a sintering furnace and sinter at 1250°C for 12 hours to obtain the desired ceramic target.

[0031] 2) Using the magnetron sputtering method, using the ceramic target in step 1) as the target, deposit a layer of Zn on the cleaned glass substrate 0.98 In 0.02 O thin film, the deposition conditions are: the dis...

example 3

[0033] Example 3: Preparation of a ZnMgO thin film embedded with ZnMgO nanosheets.

[0034] 1) Using ZnO and MgO powders with a purity of 99.99% as raw materials, according to Zn 0.90 Mg 0.10O stoichiometric ratio Zn:Mg = 0.90:0.10 ratio, weigh 30.00 g of ZnO powder and 1.6509 g of MgO powder respectively. Pour the weighed powder into a ball mill jar equipped with agate balls and ethanol, and mill it on a ball mill for 72 hours to make the powder fine and evenly mixed. Then separate the raw material and dry it at 80°C for 24 hours, add a binder and grind it, and press it into a disc shape with a diameter of about 2 inches and a thickness of 3 mm. Put the shaped green body into a sintering furnace and sinter at 1300°C for 12 hours to obtain the desired ceramic target.

[0035] 2) Using the magnetron sputtering method, using the ceramic target in step 1) as the target, deposit a layer of Zn on the cleaned quartz substrate 0.90 Mg 0.10 O thin film, the deposition condit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com