Additive for acidic texturing liquid of polycrystalline silicon wafers and application thereof

A technology of polycrystalline silicon wafers and additives, which is applied in the field of acid texturing and additives for acid texturing of polycrystalline silicon wafers. It can solve the problems of reducing the surface reflectivity of silicon wafers, reducing reflectivity, dark lines of silicon wafers, etc., and achieve good practical application value. Easy to formulate and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

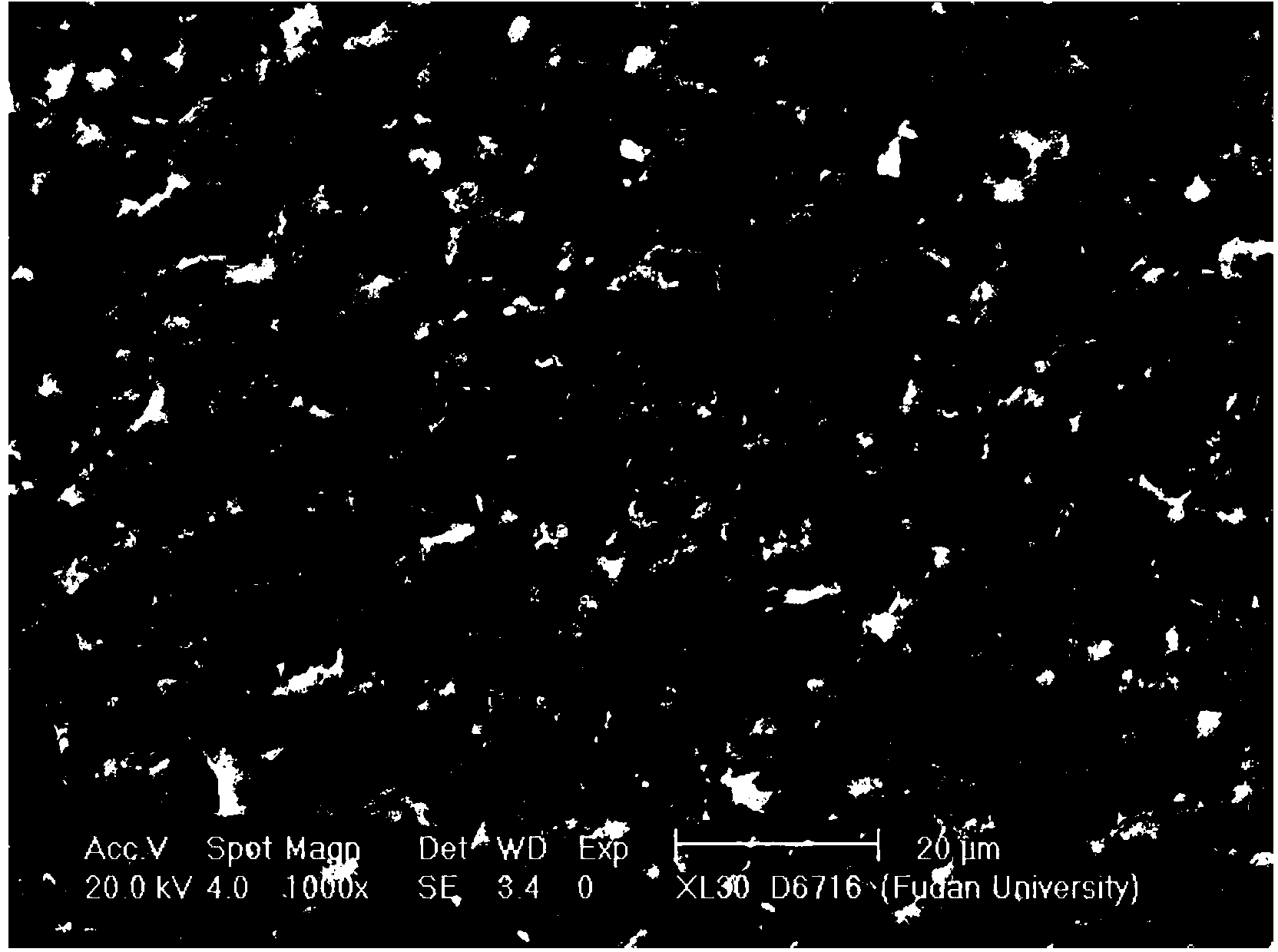

Embodiment 1

[0031] An additive for acidic texturing liquid for polycrystalline silicon wafers, comprising the following components: pentaerythritol, anhydrous sodium acetate, polyethylene glycol and deionized water.

[0032] Wherein, the weight percentage of the pentaerythritol is 0.5%, the weight percentage of the anhydrous sodium acetate is 0.5%, the weight percentage of the polyethylene glycol is 0.5%, and the balance is deionized water.

[0033] The polyethylene glycol is polyethylene glycol with a molecular weight of 200.

[0034] A method for acid texturing using the above-mentioned additives, comprising the following steps:

[0035] 1) Prepare additives: dissolve pentaerythritol, anhydrous sodium acetate and polyethylene glycol in deionized water to prepare additives;

[0036] 2) Preparation of acidic texturing solution: dissolving hydrofluoric acid and nitric acid in deionized water to prepare an acid mixed solution, and then adding the additives prepared in step 1) to the acid m...

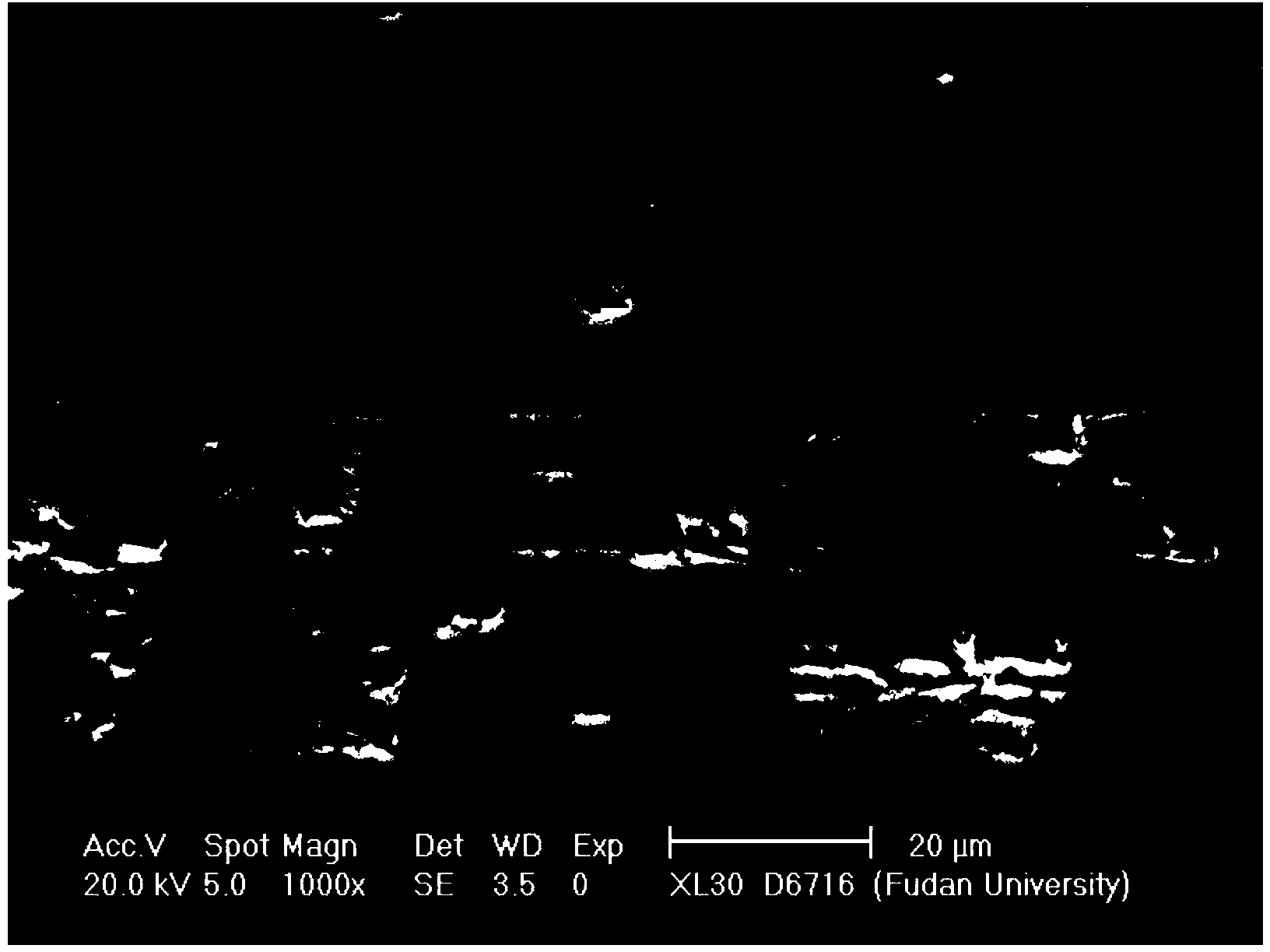

Embodiment 2

[0040] An additive for acidic texturing liquid for polycrystalline silicon wafers, comprising the following components: pentaerythritol, anhydrous sodium acetate, polyethylene glycol and deionized water.

[0041] Wherein, the weight percentage of the pentaerythritol is 2%, the weight percentage of the anhydrous sodium acetate is 2%, the weight percentage of the polyethylene glycol is 2%, and the balance is deionized water.

[0042] The polyethylene glycol is polyethylene glycol with a molecular weight of 400.

[0043] A method for acid texturing using the above-mentioned additives, comprising the following steps:

[0044] 1) Prepare additives: dissolve pentaerythritol, anhydrous sodium acetate and polyethylene glycol in deionized water to prepare additives;

[0045] 2) Preparation of acidic texturing solution: dissolving hydrofluoric acid and nitric acid in deionized water to prepare an acid mixed solution, and then adding the additives prepared in step 1) to the acid mixed s...

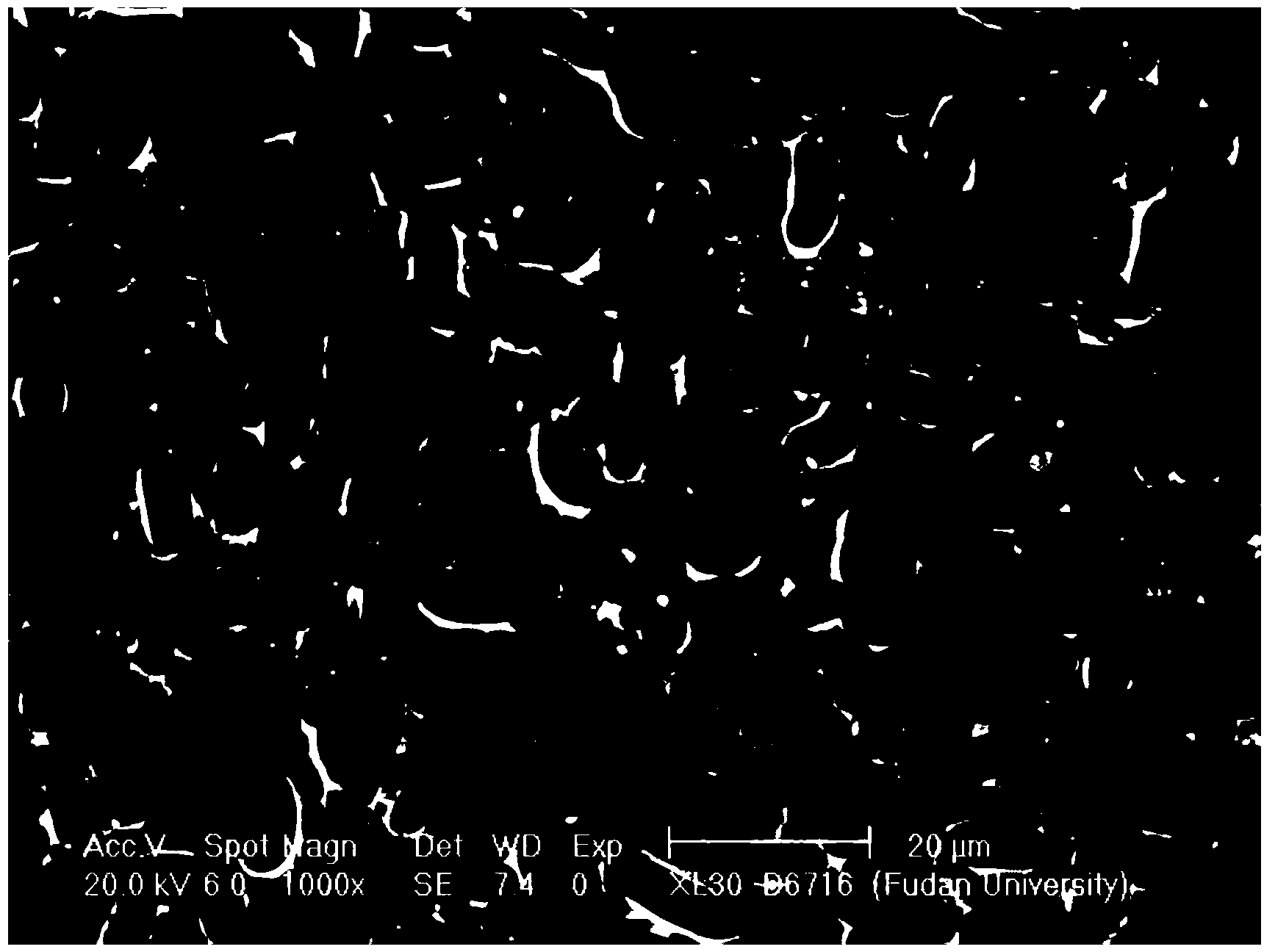

Embodiment 3

[0049] An additive for acidic texturing liquid for polycrystalline silicon wafers, comprising the following components: pentaerythritol, anhydrous sodium acetate, polyethylene glycol and deionized water.

[0050] Wherein, the weight percentage of the pentaerythritol is 1%, the weight percentage of the anhydrous sodium acetate is 1%, the weight percentage of the polyethylene glycol is 1%, and the balance is deionized water.

[0051] The polyethylene glycol is polyethylene glycol with a molecular weight of 1000.

[0052] A method for acid texturing using the above-mentioned additives, comprising the following steps:

[0053] 1) Prepare additives: dissolve pentaerythritol, anhydrous sodium acetate and polyethylene glycol in deionized water to prepare additives;

[0054] 2) Preparation of acidic texturing solution: dissolving hydrofluoric acid and nitric acid in deionized water to prepare an acid mixed solution, and then adding the additives prepared in step 1) to the acid mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com