Resolution testing standard board manufacturing method for super-resolution fluorescence microscope system

A technology of super-resolution fluorescence and microscopic systems, which is applied in the field of manufacturing super-resolution fluorescent microscopic system resolution test standard plates, can solve the problems of inapplicable observation of living samples, cumbersome process, slow observation speed, etc., and achieve simple production methods Reliable, wide excitation spectrum, and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

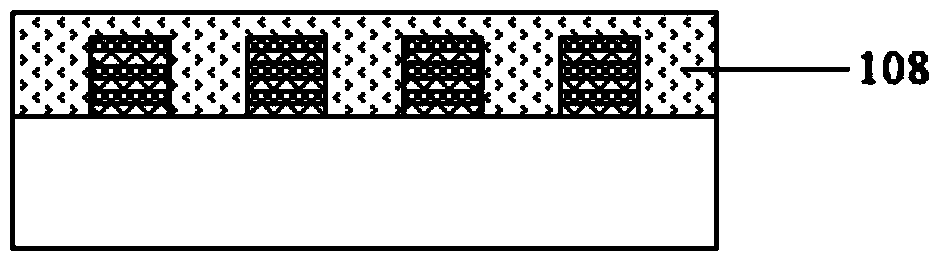

[0035] The technical innovation of the present invention is: using nano-processing technology and nano-particle self-assembly technology to make fluorescent quantum dot lines with a line width of 20nm-100nm as a fluorescent super-resolution standard plate, which can be directly used for super-resolution system testing.

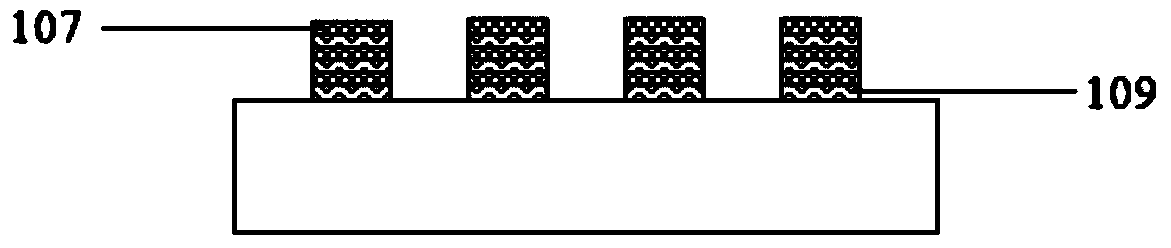

[0036] The specific structure schematic diagram of the first method of making the fluorescent super-resolution standard plate in the present invention is as follows Figure 1a to Figure 1c shown, including the following steps:

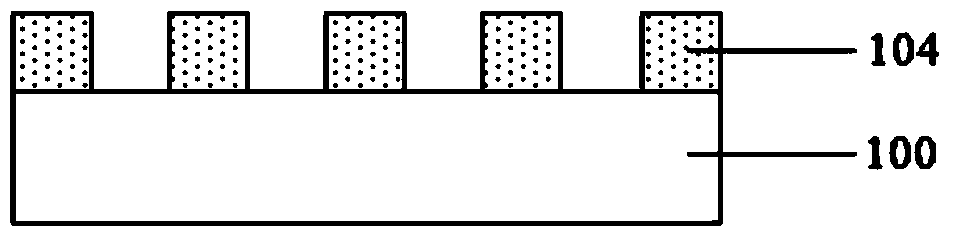

[0037] Spin coating a photoresist layer 104 on the surface of the substrate 100, the substrate 100 may be Si or quartz;

[0038] Such as Figure 1a As shown, an equidistant photoresist line structure of 20nm-100nm is formed on the photoresist layer 104 by electron beam lithography technology, so that the substrate 100 is exposed, and the thickness of the electron beam photoresist is between 50nm-150nm. Control the steepness of the pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com