Cathode composite active substance for lithium-ion batteries and preparation method of coating slurry thereof

A composite active material, lithium battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of bulging, strong hygroscopicity, and battery scrapping, and achieve the effect of reducing finished products and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A lithium battery cathode composite active material, the cathode composite active material is composed of lithium iron phosphorus oxide and lithium manganese oxide with a weight ratio of 93:8.

[0024] The invention relates to a lithium battery cathode composite active material, wherein the lithium iron phosphorus oxide is lithium iron phosphate, and the lithium manganese oxide is lithium manganese oxide.

[0025] A method for preparing a coating slurry for a positive electrode composite active material of a lithium battery, comprising the following steps:

[0026] (1) Add lithium iron phosphate, lithium manganese oxide, carbon black conductive agent, and deionized water into the mixing tank in proportion to high-viscosity kneading;

[0027] (2) Then add the water-based adhesive and deionized water into the mixing tank in proportion to carry out medium-speed dispersion;

[0028] (3) Then add the graphite conductive agent in proportion to the mixing tank for high-speed ...

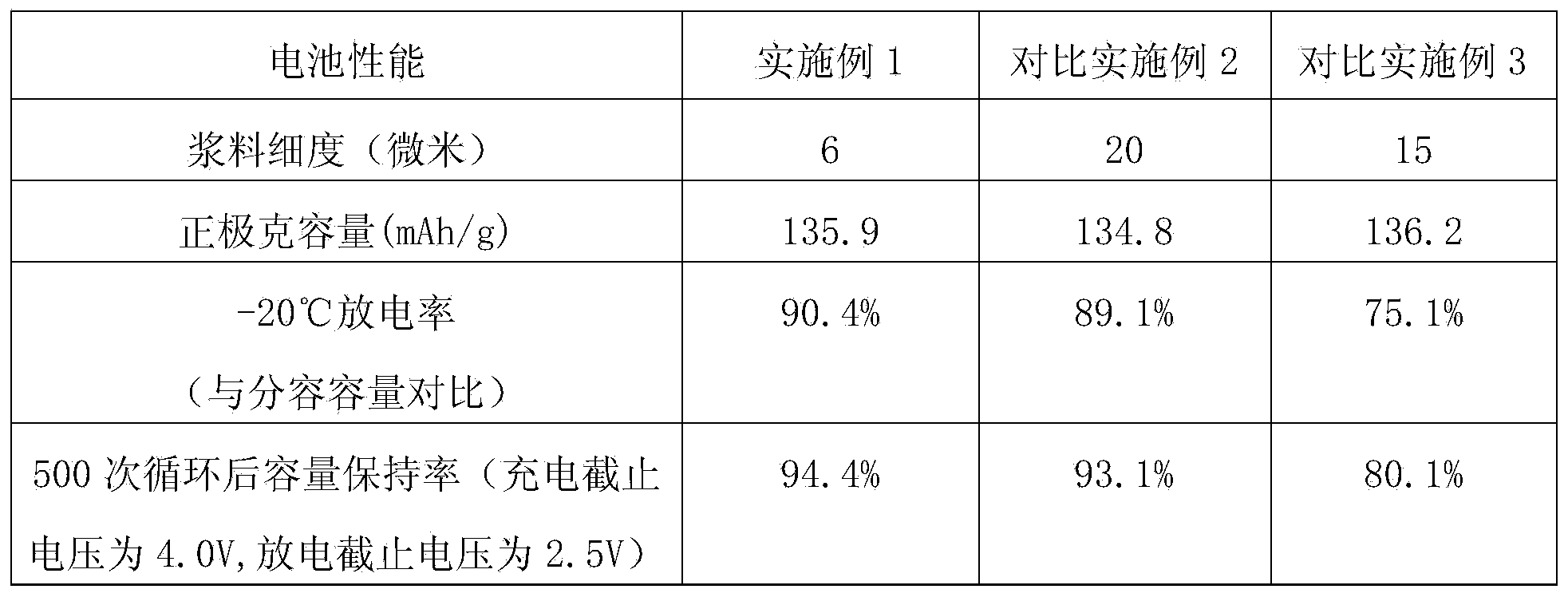

comparative example 2

[0048] This example is the preparation method of the conventional coating water-based slurry used in the manufacturing process of the positive electrode active material lithium iron phosphate and lithium manganese oxide battery:

[0049] Make a 100Ah battery according to the conventional production process of lithium iron phosphate, and stir the positive electrode according to the following stirring process

[0050]1. Weigh a certain weight of water-based glue and deionized water according to the recipe process requirements, first add 90% of the weighed amount of deionized water into the mixing tank, then add the weighed amount of water-based glue, turn on the revolution "30Hz" and rotate "25Hz" stirred for 0.5h.

[0051] 2. Weigh a certain weight of carbon black conductive agent and graphite conductive agent according to the recipe process requirements and add them to the water-based glue diluted in the mixing tank, and disperse at high speed at "35Hz" for revolution and "35H...

comparative example 3

[0056] This example is the preparation method of conventional coating water-based slurry used in the manufacturing process of pure lithium iron phosphate battery:

[0057] Make a 100Ah battery according to the conventional production process of lithium iron phosphate, and stir the positive electrode according to the following stirring process

[0058] 1. Weigh a certain weight of water-based glue and deionized water according to the recipe process requirements, first add 90% of the weighed amount of deionized water into the mixing tank, then add the weighed amount of water-based glue, turn on the revolution "30Hz" and rotate "25Hz" stirred for 0.5h.

[0059] 2. Weigh a certain weight of carbon black conductive agent and graphite conductive agent according to the recipe process requirements and add them to the water-based glue diluted in the mixing tank, and disperse at high speed at "35Hz" for revolution and "35Hz" for rotation for 2 hours.

[0060] 3. Weigh a certain weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com