Anticoagulation coating material and preparation method thereof

A coating material and anti-coagulation technology, applied in the field of anti-coagulation coating materials and their preparation, can solve the problems of unstable anti-coagulation effect, not long-term, poor biocompatibility, etc., and achieve a significant anti-coagulation effect. , Not easy to be deactivated, the effect of stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A kind of preparation method of anticoagulation coating material provided by the invention comprises the following steps:

[0037] (1) Prepare 2-(N-morpholine)ethanesulfonic acid (MES) buffer solution with a concentration of 0.1mol / L and adjust the pH value to 6.4.

[0038] (2) Preparation of sodium hyaluronate solution:

[0039] Take sodium hyaluronate (HA, molecular weight about 2 million) in 2-(N-morpholine) ethanesulfonic acid buffer solution (MES, 0.1M, pH=6.4), and dissolve it fully to obtain sodium hyaluronate solution. The sodium hyaluronate solution has a concentration of 1 mg / ml to 20 mg / ml. Magnetic stirring can be used to accelerate the dissolution of sodium hyaluronate, stirring for 12 hours. The prepared sodium hyaluronate solution can be sealed and frozen for future use.

[0040](3) Preparation of hirudin solution:

[0041] Take the hirudin in the MES buffer, so that the hirudin is uniformly dispersed in the MES buffer. In order to increase the solub...

Embodiment 1

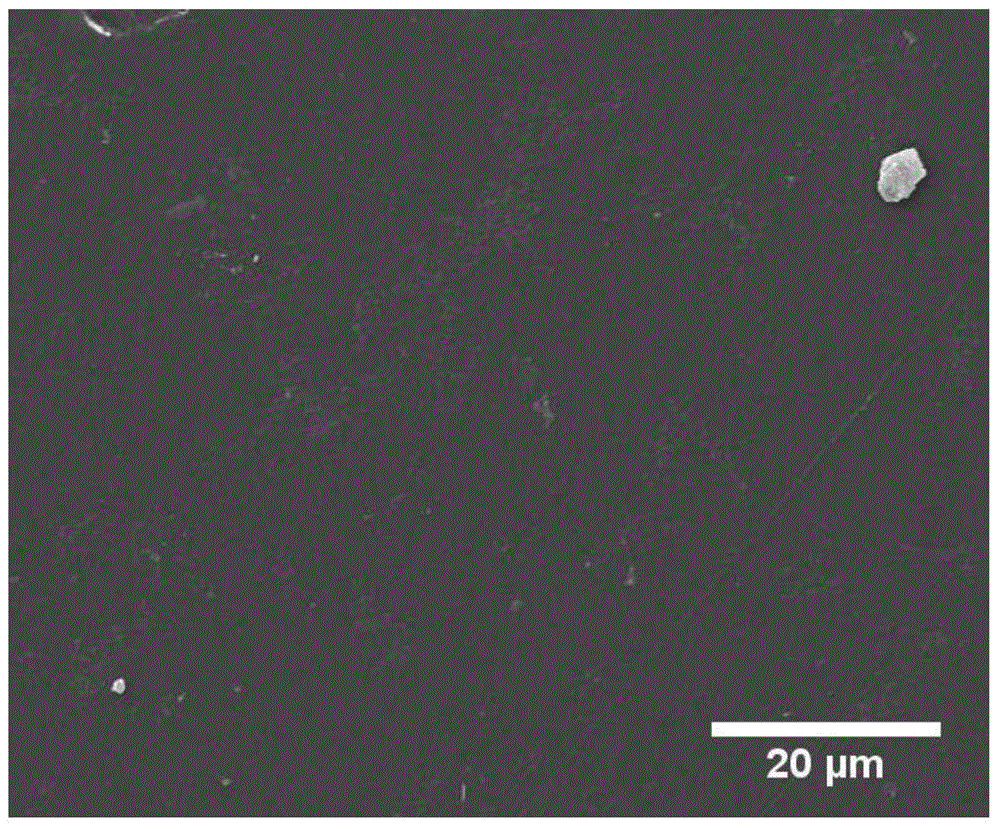

[0050] An anticoagulant coating material comprises sodium hyaluronate and hirudin, the sodium hyaluronate forms a gel network, and the hirudin is covalently bonded to the sodium hyaluronate through an amide bond. The mass ratio of the hirudin to the sodium hyaluronate is 1:1. The anticoagulant coating material also includes a cross-linking agent, 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide (EDC) and N-hydroxysuccinimide (NHS) .

[0051] The preparation method of described anticoagulant coating material, comprises the following steps:

[0052] (1) Prepare 2-(N-morpholine)ethanesulfonic acid (MES) buffer solution with a concentration of 0.1mol / L and adjust the pH value to 6.4.

[0053] (2) Prepare sodium hyaluronate solution.

[0054] Take sodium hyaluronate (HA, molecular weight about 2 million) in 2-(N-morpholine) ethanesulfonic acid buffer solution (MES, 0.1M, pH=6.4), and dissolve it fully to obtain sodium hyaluronate solution. The concentration of sodium hyaluronate ...

Embodiment 2

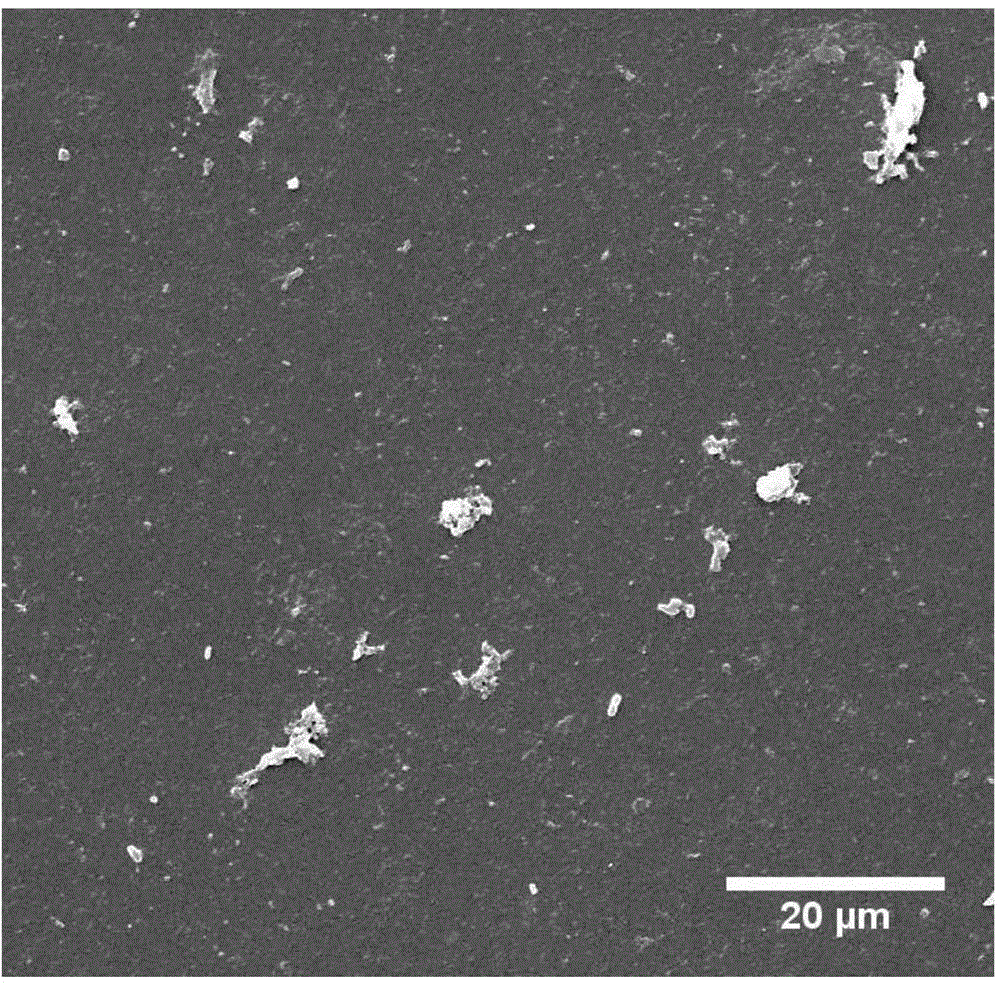

[0066] An anticoagulant coating material comprises sodium hyaluronate and hirudin, the sodium hyaluronate forms a gel network, and the hirudin is covalently bonded to the sodium hyaluronate through an amide bond. The mass ratio of the hirudin to the sodium hyaluronate is 1:3. The anticoagulant coating material also includes a cross-linking agent, 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide (EDC) and N-hydroxysuccinimide (NHS) .

[0067] The preparation method of described anticoagulant coating material, comprises the following steps:

[0068] (1) Prepare 2-(N-morpholine)ethanesulfonic acid (MES) buffer solution with a concentration of 0.1mol / L and adjust the pH value to 6.4.

[0069] (2) Prepare sodium hyaluronate solution.

[0070] Take sodium hyaluronate (HA, molecular weight about 2 million) in 2-(N-morpholine) ethanesulfonic acid buffer solution (MES, 0.1M, pH=6.4), and dissolve it fully to obtain sodium hyaluronate solution. The concentration of sodium hyaluronate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com