Water-based foam stabilizer, preparation method of foam stabilizer and water-based foam system with ultrahigh stability

A technology of foam stabilizer and foam system, which is applied in the direction of chemical instruments and methods, solid separation, drilling composition, etc., can solve the problem that the stability of water-based foam cannot meet the requirements well, affect the technical application effect, and water-based Foam stability is not high enough to achieve the effect of high foam stability, low gas permeability and excellent foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: hydrophobically modified polyacrylamide

[0036] 1. Preparation of hydrophobically modified polyacrylamide

[0037] Dissolve 10g of acrylamide and 0.5g of EDTA in deionized water, then add 3g of sodium lauryl sulfate and 0.2g of acrylate (the number of carbons in the alkyl chain is 16). The reactor was placed in a constant temperature water bath, and N 2 Add the initiator after 30 minutes, keep the temperature at 50°C and stir for 20 hours. Hydrophobically modified polyacrylamide was obtained, and the molecular weight of the obtained product was about 150,000.

[0038] x / (x+y)=90%, y / (x+y)=10%, molar ratio.

[0039] 2. Preparation of foam stabilizer

[0040] In deionized water, add hydrophobically modified polyacrylamide in proportion, stir and mix evenly, prepare a solution with a concentration of 0.1wt%, keep the solution temperature at 30°C and stir for half an hour. A foam stabilizer solution is obtained.

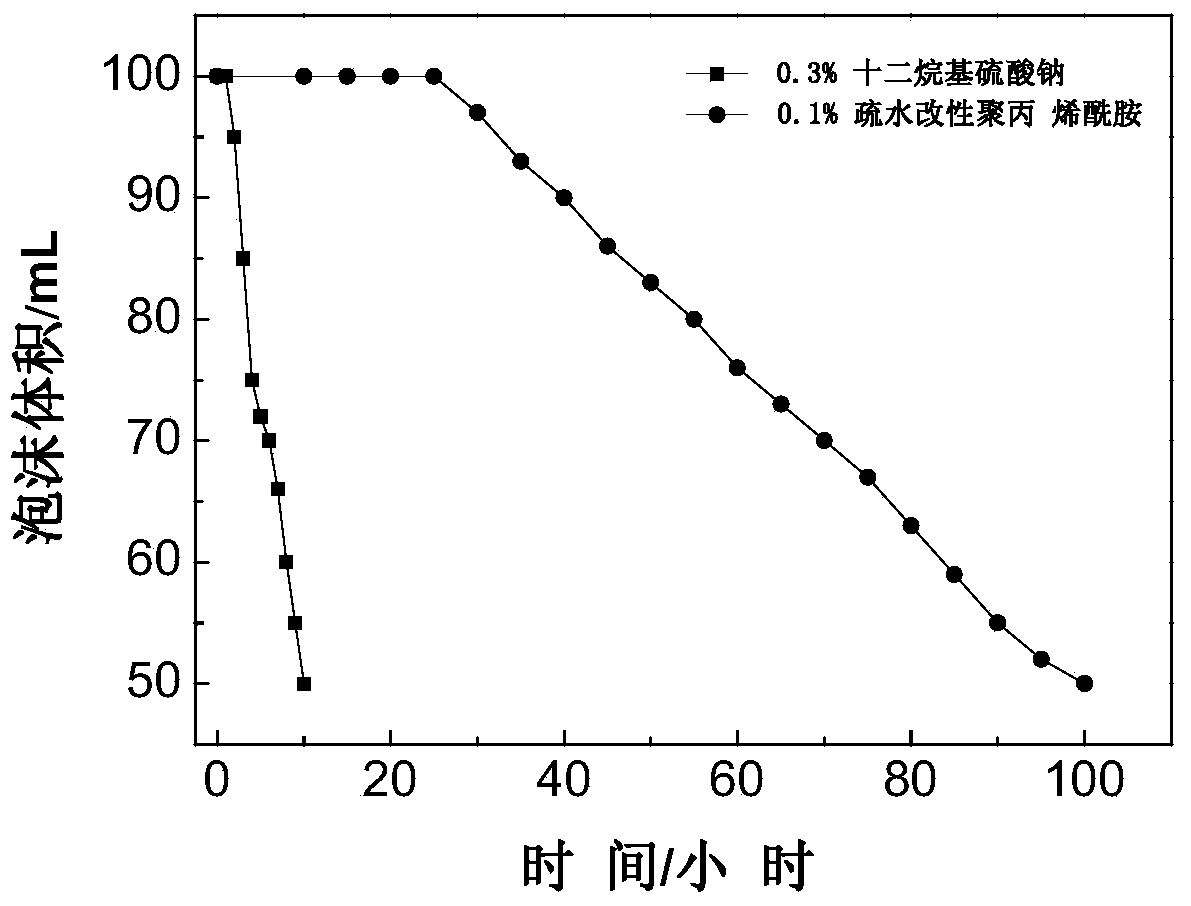

[0041] 3. Investigation on foam stabi...

Embodiment 2

[0045] Embodiment 2: hydrophobically modified sodium polystyrene sulfonate

[0046] 1. Preparation of hydrophobically modified sodium polystyrene sulfonate

[0047] Dissolve 12g of sodium styrene sulfonate and 0.5g of EDTA in deionized water, then add 3.5g of sodium dodecylbenzenesulfonate and 0.25g of acrylate (the number of carbons in the alkyl chain is 18). The reactor was placed in a constant temperature water bath, and N 2 Add the initiator after 30 minutes, keep the temperature at 50°C and stir for 20 hours. Hydrophobically modified sodium polystyrene sulfonate was obtained, and the molecular weight of the obtained product was about 180,000.

[0048] x / (x+y)=85%, y / (x+y)=15%, molar ratio.

[0049] 2. Preparation of foam stabilizer

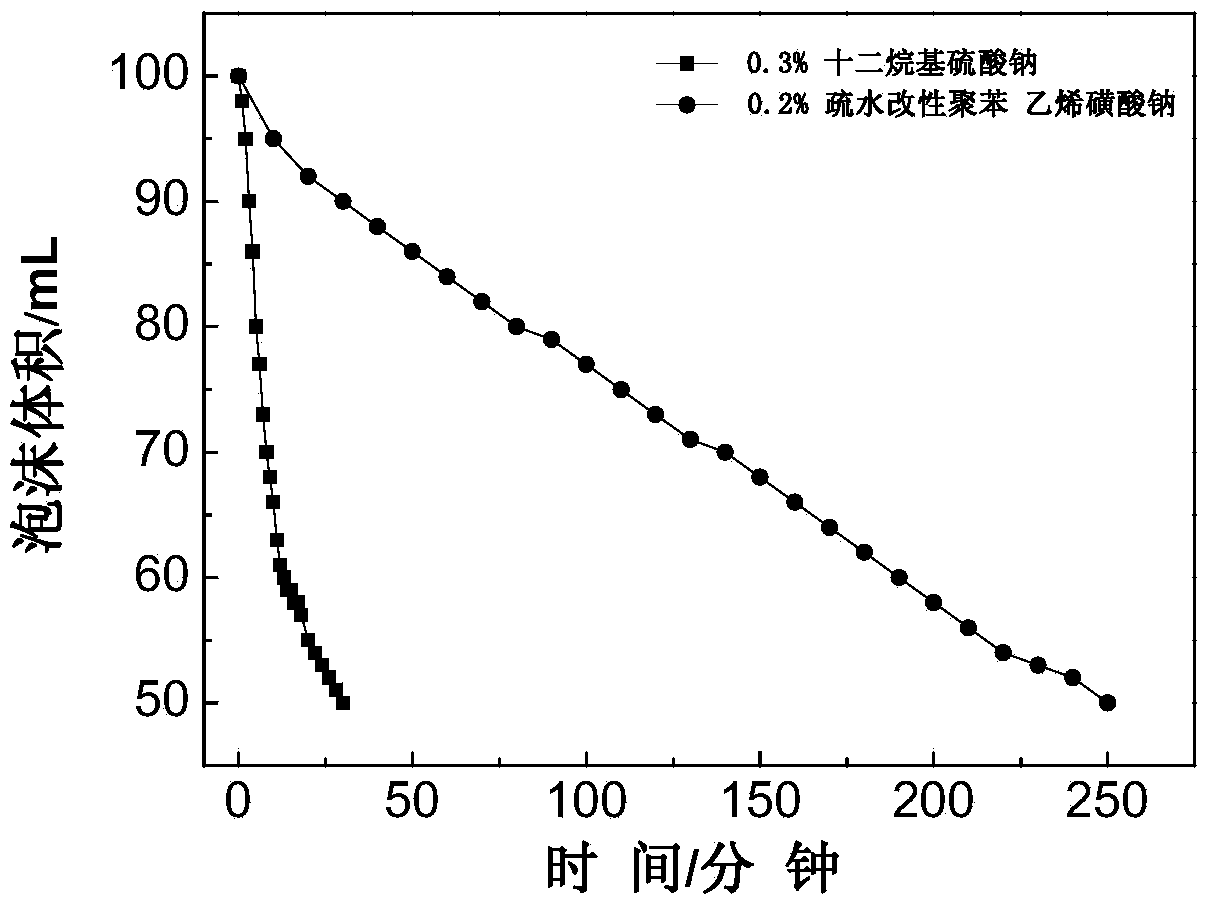

[0050] In deionized water, add hydrophobically modified sodium polystyrene sulfonate in proportion, stir and mix evenly, and prepare a solution with a concentration of 0.2wt%, and keep the temperature of the solution at 30°C for half an...

Embodiment 3

[0055] Embodiment 3: hydrophobically modified polyvinyl alcohol

[0056] 1. Preparation of hydrophobically modified polyvinyl alcohol

[0057] Dissolve 8g of vinyl alcohol and 0.5g of EDTA in deionized water, then add 2g of sodium dodecylsulfonate and 0.15g of acrylate (the number of carbons in the alkyl chain is 8). The reactor was placed in a constant temperature water bath, and N 2 Add the initiator after 30 minutes, keep the temperature at 50°C and stir for 20 hours. Hydrophobically modified polyvinyl alcohol is obtained, and the molecular weight of the product is about 80,000.

[0058] x / (x+y)=80%, y / (x+y)=20%, molar ratio.

[0059] 2. Preparation of foam stabilizer

[0060] Add hydrophobically modified polyethylene glycol to the simulated formation water (total salinity of 7000ppm) in the Shengli Gudong oil production area, and prepare a 0.3wt% solution at 60°C. Stir for 30min. As a foam stabilizer solution.

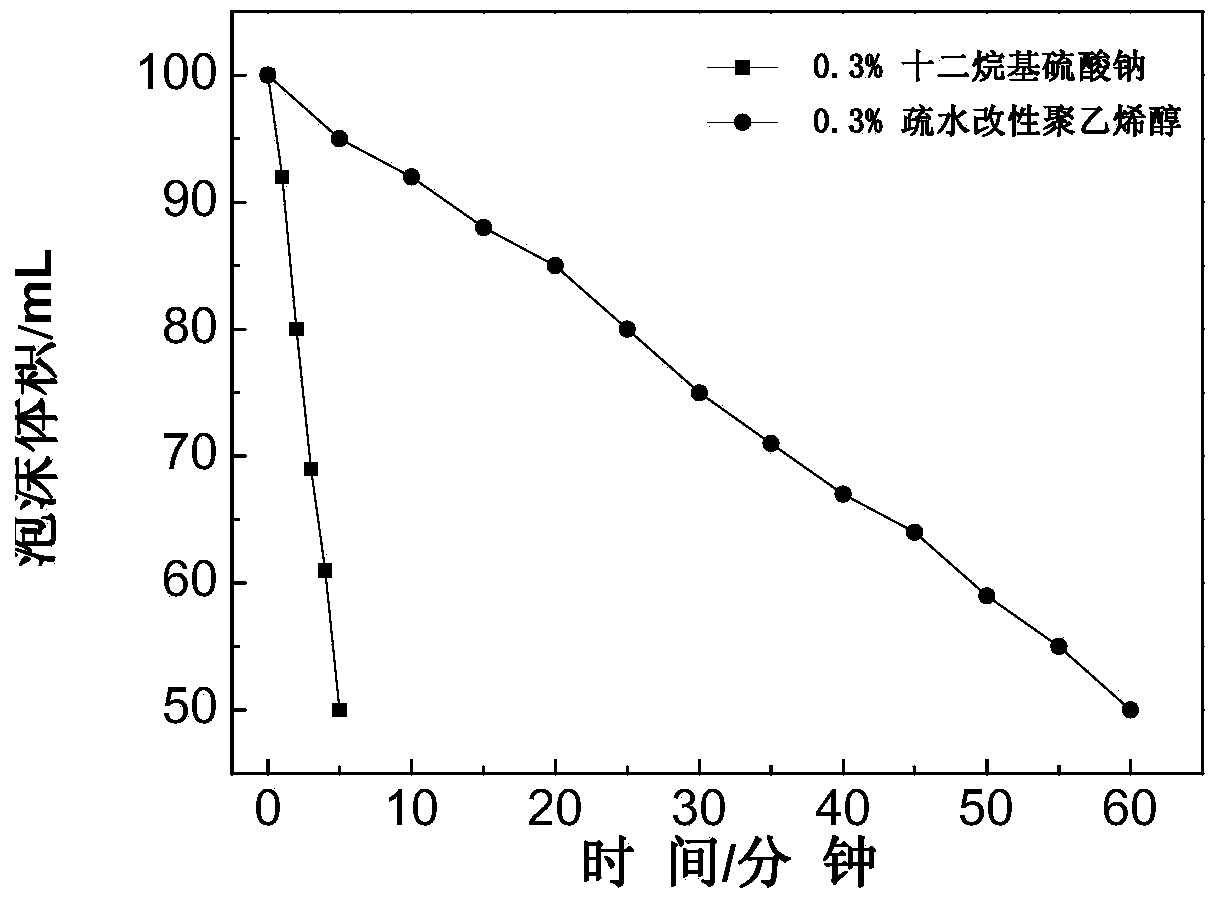

[0061] 3. Investigation on foam stabilization effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com