Stepless speed regulating system for magnetic gear motor rotation

A technology of motor transmission and stepless speed regulation, which is applied to the layout of multiple different prime movers, power devices, and air pressure power devices of general power devices, and can solve the problem of increasing the number of ends, increasing the number of pole pieces, and reducing the efficiency of the motor. problems, to reduce the influence of magnetic field mutual coupling, reduce the difficulty of winding and processing, and avoid gear wear and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings.

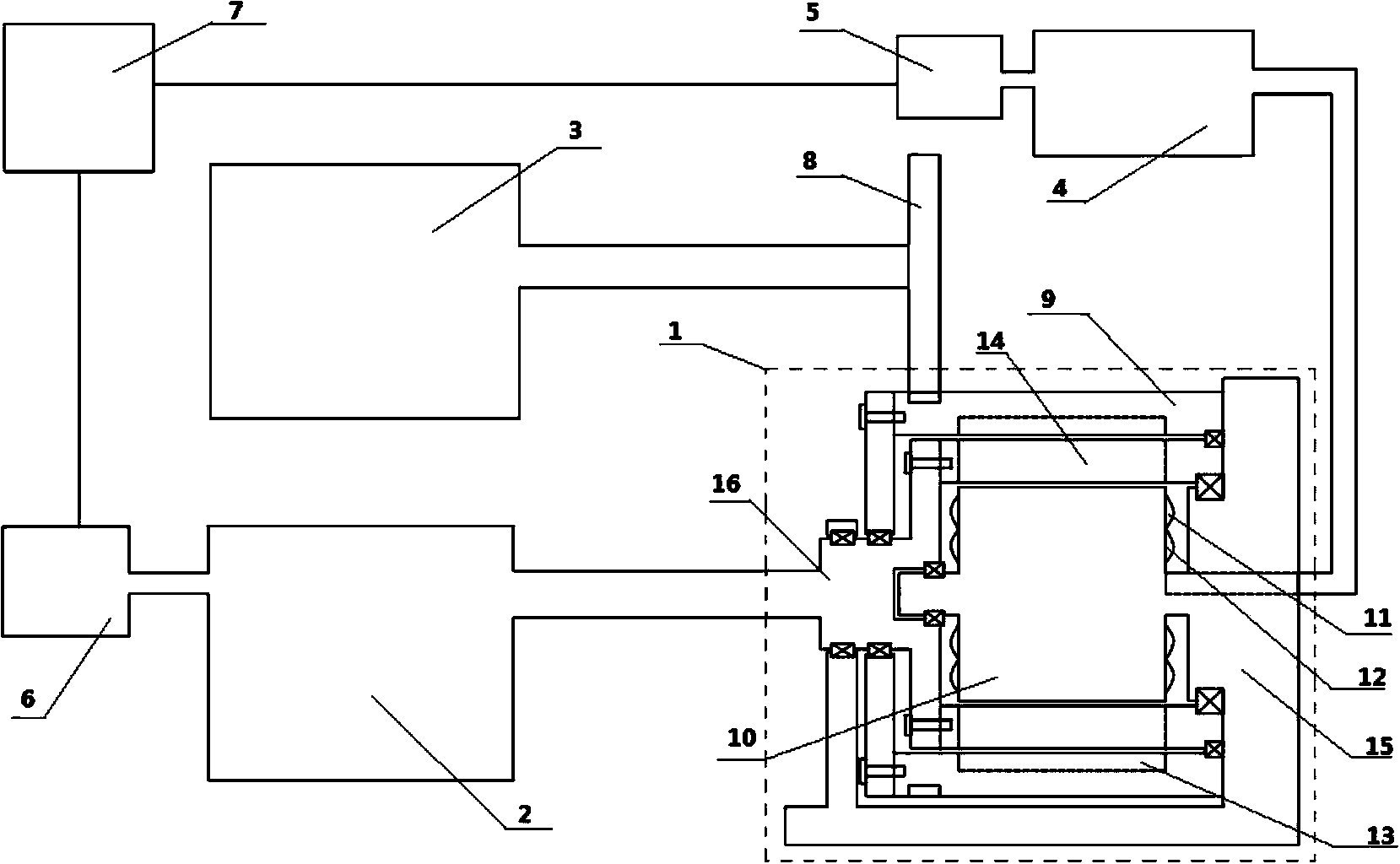

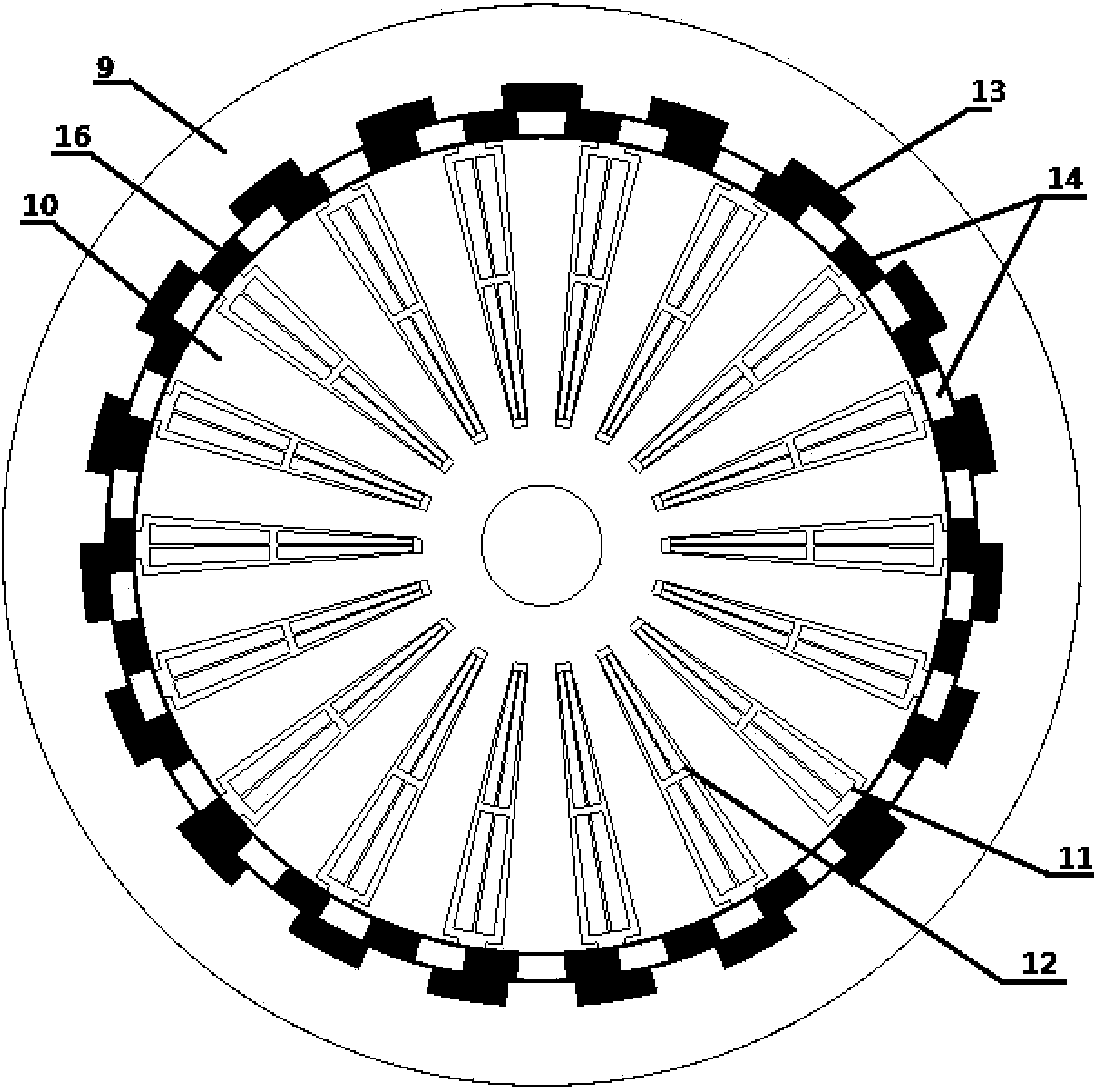

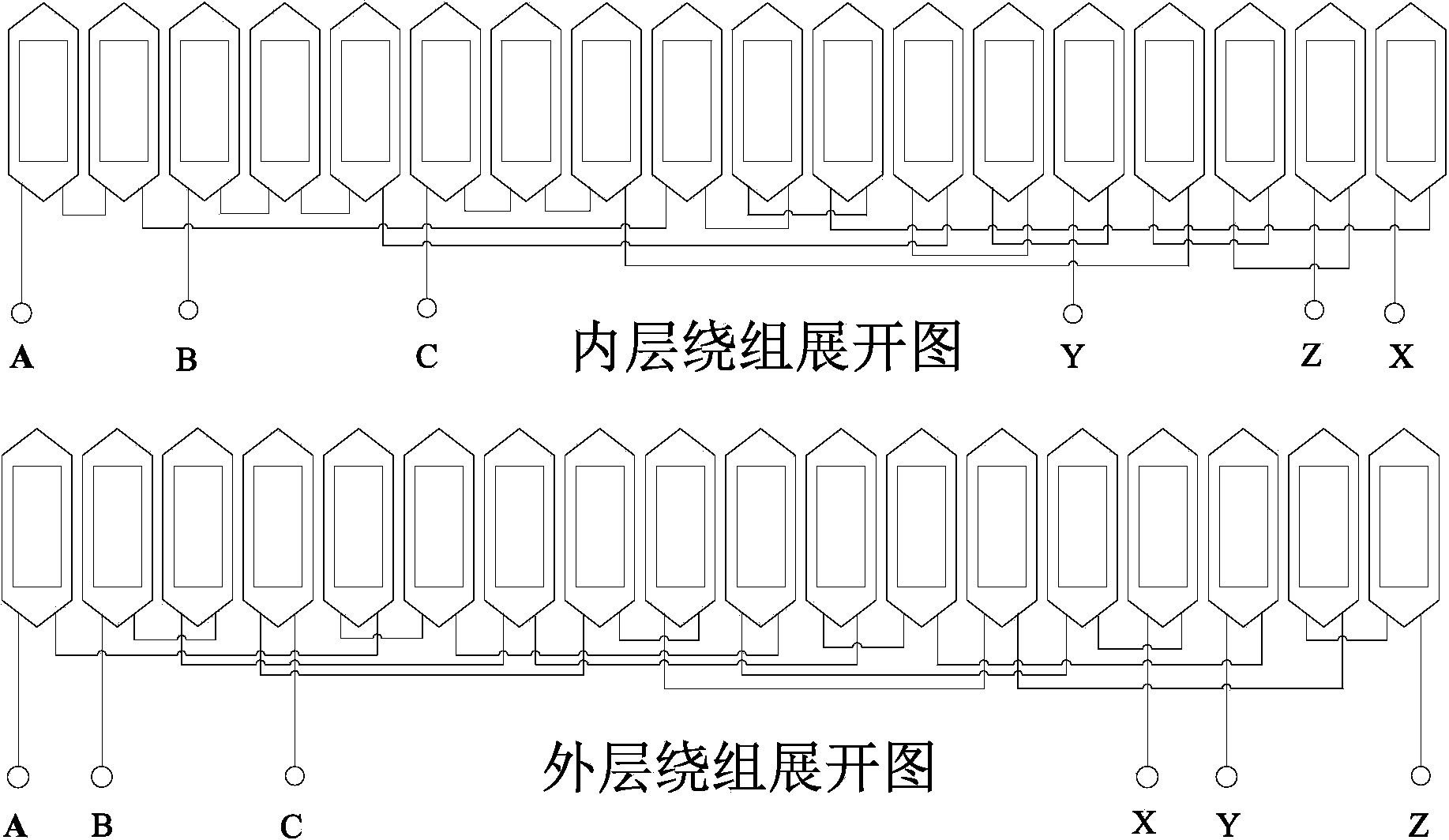

[0015] A stepless speed regulation system driven by a magnetic gear motor such as figure 1 As shown, it includes a double-rotor magnetic gear motor 1 , an engine 2 , a wheel final drive 3 , an inverter 4 , a motor control unit 5 , an engine control unit 6 , a power management unit 7 , and a differential gear 8 . The power management unit 7 is respectively connected to the motor control unit 5 and the engine control unit 6, the motor control unit 5 controls the inverter 4 to drive the double-rotor magnetic gear motor 1, the engine control unit 6 controls the operation of the engine 2, and the engine 2 is connected to the double-rotor magnetic gear motor. gear motor 1. The wheel main reducer 3 is connected to the dual-rotor magnetic gear motor 1 through a differential gear 8 .

[0016] Among them, the engine 2 can be an ordinary passenger car engine; the power manageme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com