Up-flow anaerobic biological reaction/precipitator used for wastewater treatment

A biological reaction and wastewater treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as shortening hydraulic retention time, pressure imbalance, affecting sedimentation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

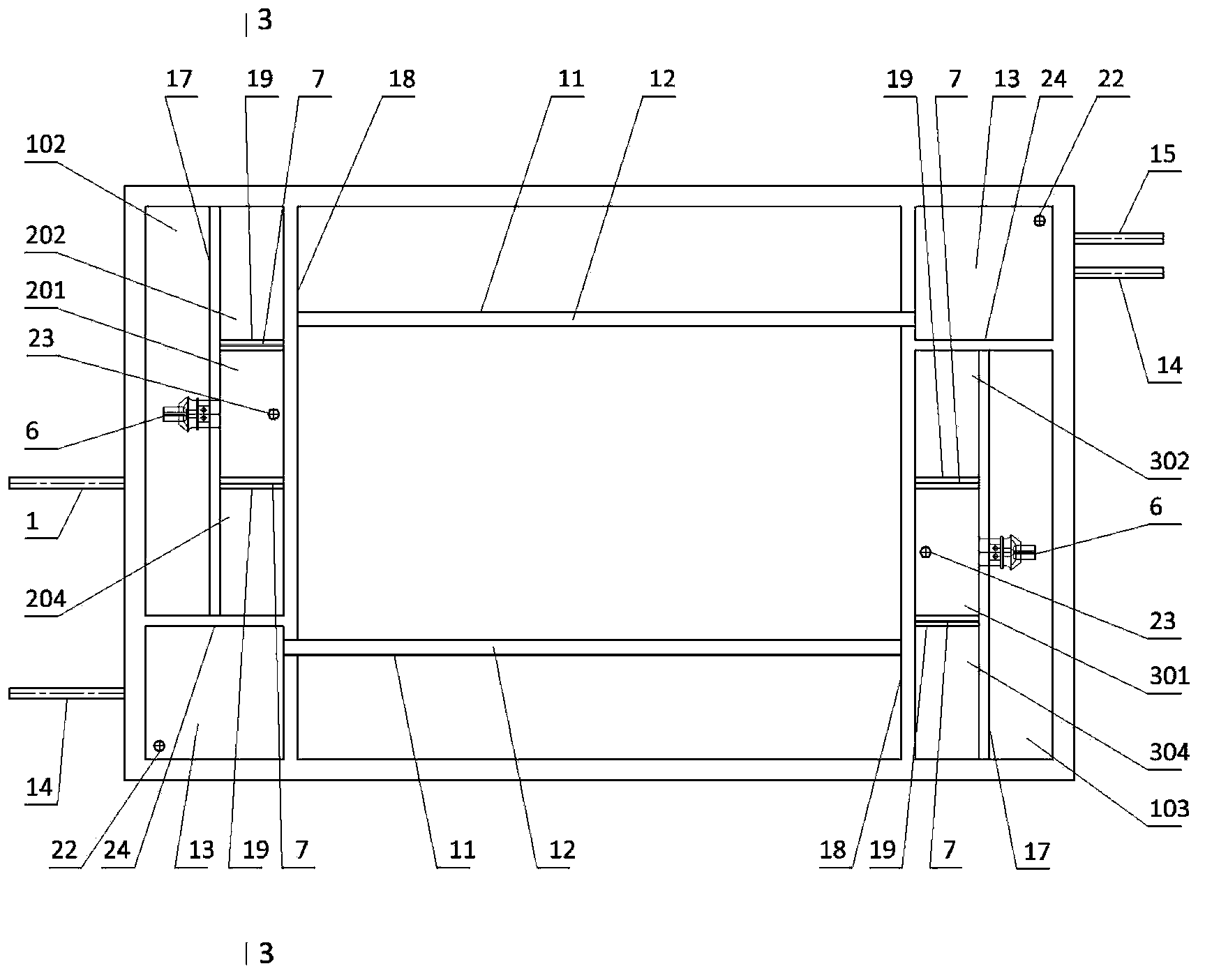

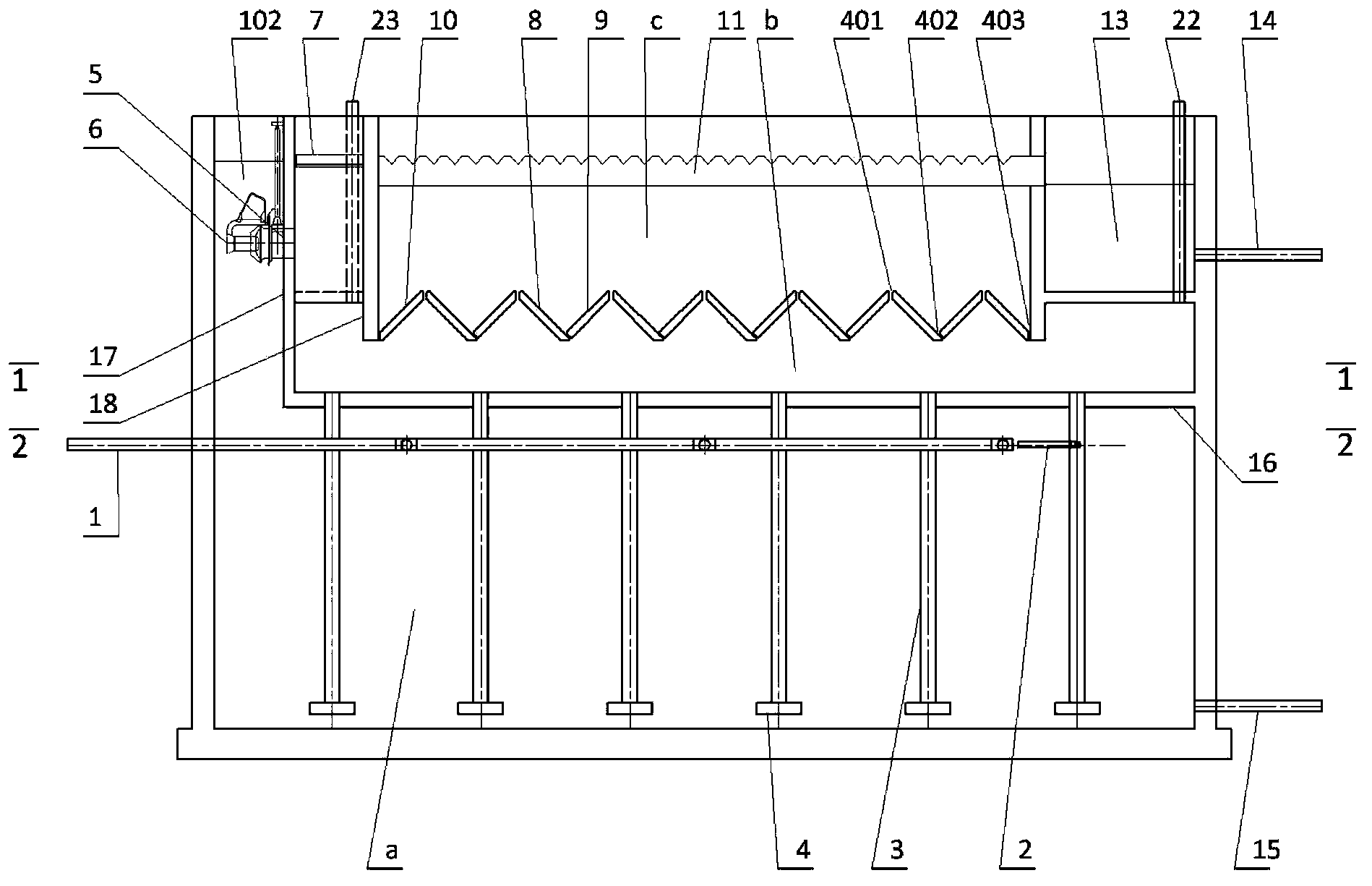

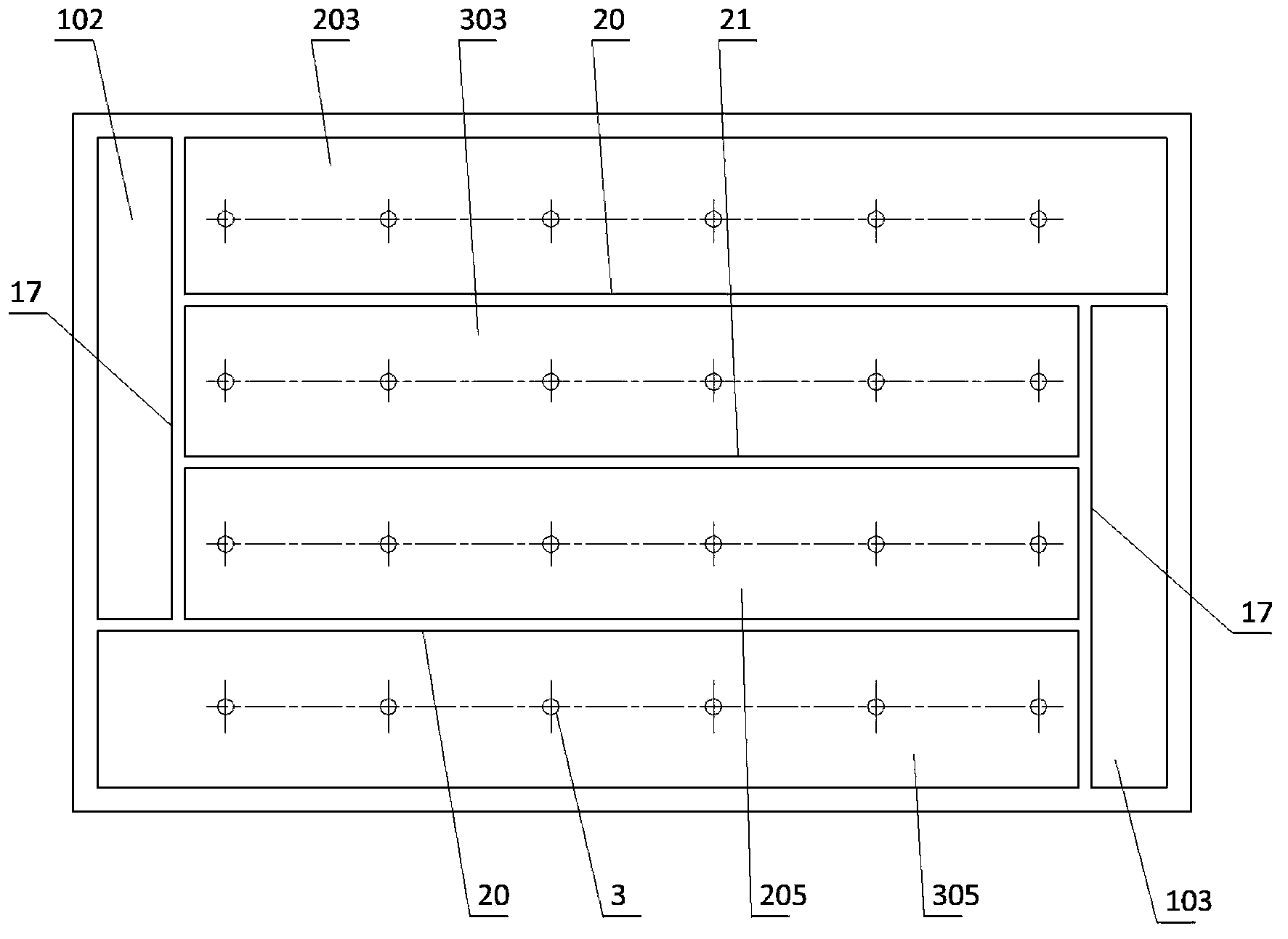

[0092] An anoxic biological reactor / settler for wastewater treatment.

[0093] The reaction / settler is a rectangular, integrated structure, including: reaction zone a, water distribution zone b, sedimentation zone c, water inlet and return system, water outlet system and sludge discharge and exhaust system.

[0094] The reaction zone a is arranged at the lower part of the reaction / settler, including: a main reaction zone 101, a left upflow well 102 and a right upwelling well 103; Connect the vertical upflow well partition wall 17, and form two left and right square upflow wells between the upflow well partition wall 17 and the inner wall of the reaction / settler. .

[0095] The settling area c is set in the middle of the upper part of the reaction / sedimenter. It is rectangular, closed around, the upper part is open, and the bottom is equipped with a water distribution / sludge return system. The wall is the partition wall 18 of the sedimentation area; the water distribution / mud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com