Ultrasonic extraction method of Acanthopanax giraldii polysaccharide

The technology of the polysaccharide and extraction method is applied in the field of ultrasonic extraction of the polysaccharide of Rhizoma Rhizoma Rhizoma Rhizoma, and can solve the problems of less research on the polysaccharide extraction process of Rhizoma Rhizoma Rhizoma Rhizoma, only 2.5%, low extraction efficiency, etc., and achieves improvement. The effect of protein removal, low extraction temperature and improved extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

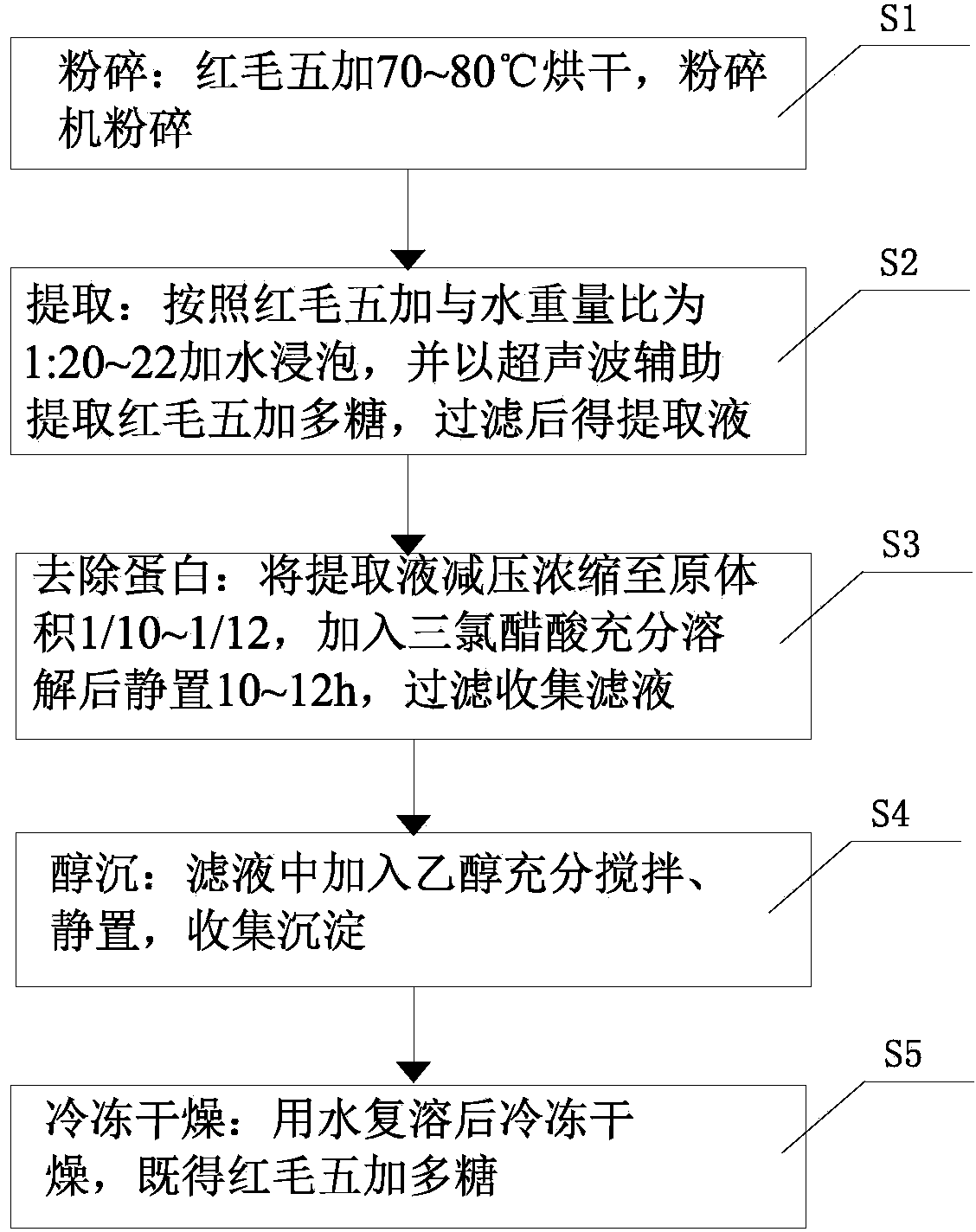

[0054] Embodiment 1: according to the following steps to extract the polysaccharide

[0055] (1) Pulverizing step: after drying the five-five-natured orchids at 80°C to constant weight, pulverize them to 140-150 mesh.

[0056] (2) Ultrasonic extraction step: take 500g of orientalis micropowder, add 11L of water and soak for 5h, the ultrasonic frequency is 30KHz, the ultrasonic power is 500W, the extraction temperature is 65°C, extract for 50min, filter, and collect the filtrate.

[0057] (3) Protein removal step: pressure -0.09MPa, temperature 70°C, concentrate the extract to 1L under reduced pressure, add 50g of trichloroacetic acid, let stand for 10h to precipitate after fully dissolved, filter and collect the filtrate.

[0058] (4) Alcohol precipitation step: add water to 6.16L, dilute the sugar concentration in the solution to 4mg / mL, then add 18.5L of absolute ethanol, stand at 0°C for 24h, and collect the precipitate by filtration.

[0059] (5) Freeze-drying step: redis...

Embodiment 2

[0060] Embodiment 2: According to the following method steps, the polysaccharides of Acanthopanax polysaccharides are extracted

[0061] (1) Pulverization step: pulverize the five-five-scenteda to 135-145 mesh at 70°C.

[0062] (2) Ultrasonic extraction step: take 2000g of orangyana micropowder, add 40L of water and soak for 3 hours, the ultrasonic frequency is 50KHz, the ultrasonic power is 600W, the extraction temperature is 75°C, extract for 40min, filter, and collect the filtrate.

[0063] (3) Protein removal step: the pressure is -0.11MPa, the temperature is 60°C, the extract is concentrated under reduced pressure to 3.4L, 187g of trichloroacetic acid is added, and after being fully dissolved, stand for 12 hours to precipitate, filter and collect the filtrate.

[0064] (4) Alcohol precipitation step: add water to 18.5L, dilute the sugar concentration in the solution to 6mg / mL, then add 75.5L of absolute ethanol, stand at 4°C for 12h, and collect the precipitate by filtrat...

Embodiment 3

[0066] Embodiment 3: according to the following method steps to extract the polysaccharides of Acanthopanax polysaccharides

[0067] (1) Pulverizing step: pulverize the five-five-flowered five-five-scented root at 75°C to 130-140 mesh.

[0068] (2) Ultrasonic extraction step: take 1000g of orientalis micropowder, add 21L of water and soak for 4h, ultrasonic frequency is 40KHz, ultrasonic power is 400W, extraction temperature is 70°C, extract for 45min, filter, and collect the filtrate.

[0069] (3) Protein removal step: pressure -0.10MPa, temperature 65°C, concentrate the extract to 2.1L under reduced pressure, add 126g trichloroacetic acid, wait for 11h to precipitate after fully dissolved, filter and collect the filtrate.

[0070] (4) Alcohol precipitation step: add water to 11.2L, dilute the sugar concentration in the solution to 5mg / mL, then add 39L of absolute ethanol, stand at 2°C for 18h, and collect the precipitate by filtration.

[0071] (5) Freeze-drying step: redis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com