Outdoor glass fiber reinforced mildewproof and antibacterial poly carbonic acid resinous polymer

A polycarbonate resin, anti-mildew and antibacterial technology, applied in the field of polymer composite materials, can solve the problems of difficult molding, poor fluidity, and decreased flexural strength and flexural modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

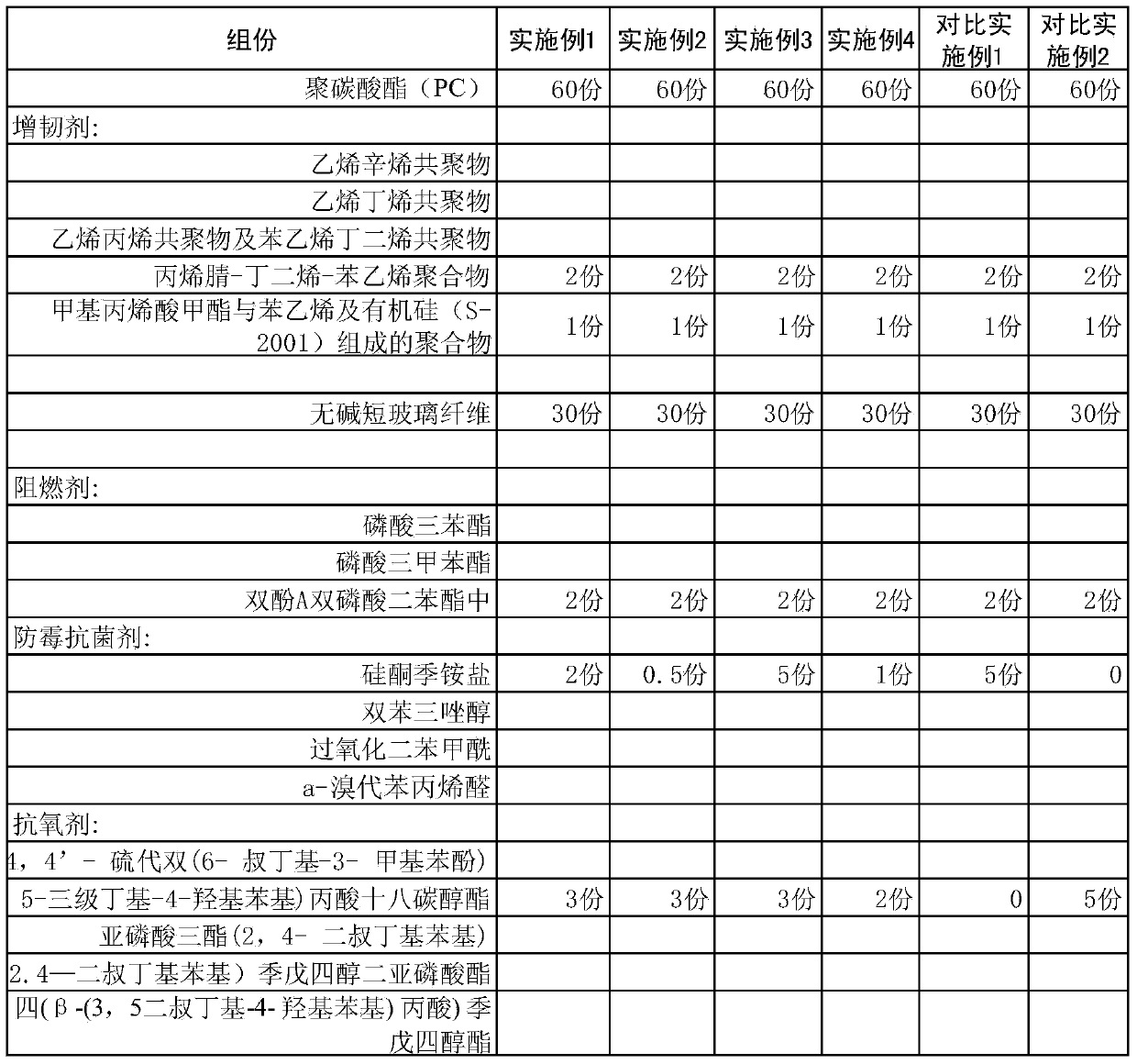

[0012] The present invention will be further described below in conjunction with specific preferred embodiments 1 to 4 and comparative examples 1 to 2 of the present invention, but the examples and comparative examples are only used to illustrate the present invention rather than limit the present invention.

[0013] The composition of a kind of outdoor glass fiber reinforced anti-mold and antibacterial polycarbonate resin polymer of preferred embodiments 1 to 4 of the present invention and comparative examples 1 to 2 is as shown in Table 1 in parts by weight:

[0014] Table I:

[0015]

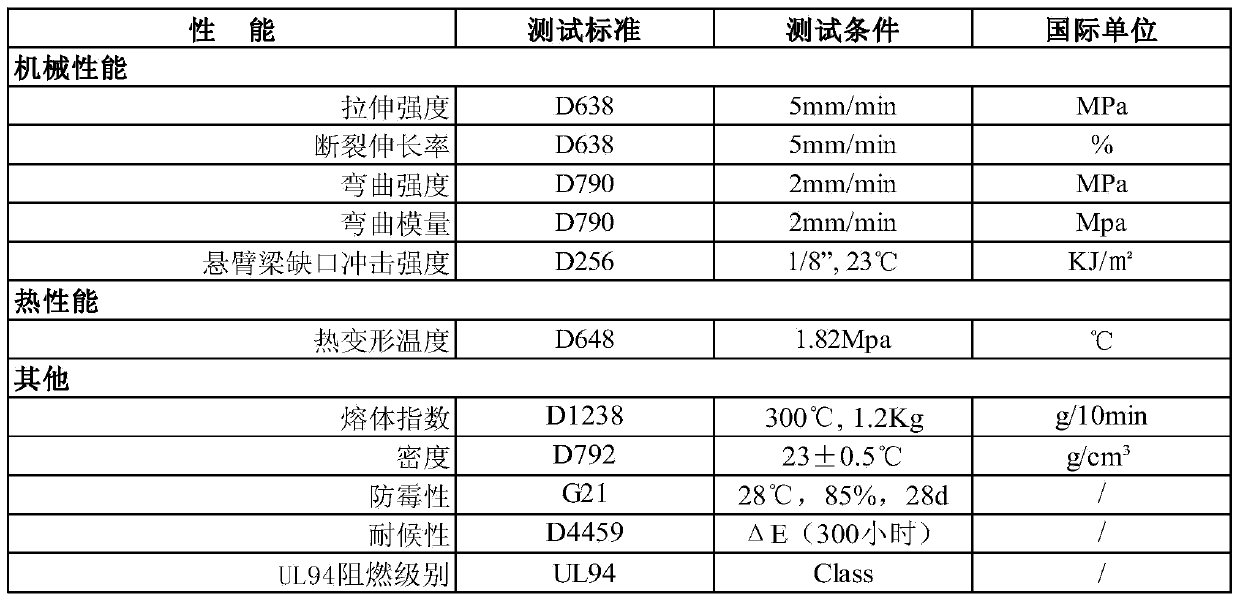

[0016] The preferred embodiment 1 to 4 of the present invention and comparative example 1 to 2 a kind of outdoor glass fiber reinforced anti-mildew and antibacterial polycarbonate resin polymer, its preparation method all is extruded granulation after each component is mixed evenly, namely Obtain cold-resistant anti-mildew and anti-bacterial series polycarbonate resin polymers. In this ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com