Single-component epoxy coating and preparation method thereof

An epoxy coating, one-component technology, applied in the field of coatings, can solve the problems of inapplicable substrates and corrosive environments, poor adhesion of light metal substrates, complicated and complicated operations, etc., and achieves a simple and fast preparation method, not easy to fall off or Cracking, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

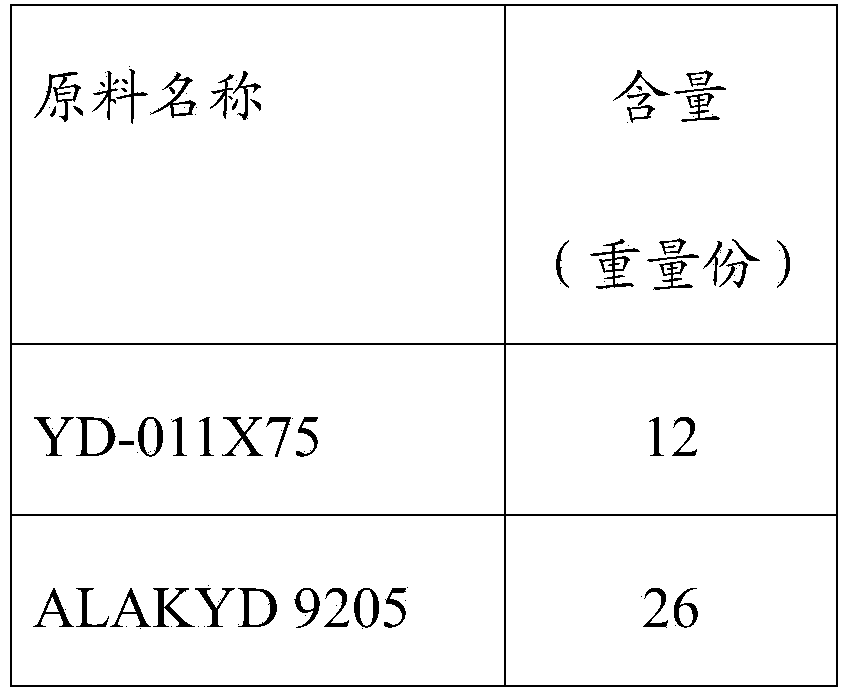

Embodiment 1

[0025]

[0026]

[0027] The preparation method is: put 12 parts by weight of epoxy resin (YD011X75), 26 parts of high molecular weight epoxy resin (ALAKYD9205), and 0.4 parts by weight of silane coupling agent (KBM403) into the dispersion kettle, stir evenly, and then Add the following components respectively: 11 parts by weight of iron red powder, 24 parts by weight of talc powder, 5 parts by weight of anti-rust pigment, 4 parts by weight of dehydrating agent (OFM) and some solvents, disperse at high speed for 30 minutes, and then use sand mill grinder or three-roll mill to standard fineness, put 1.6 parts by weight of ketimine, 0.2 parts by weight of defoamer (AC-300) and 2 parts by weight of thixotropic agent (HPA202) under low-speed stirring, and mix After uniformity, filter and seal the package.

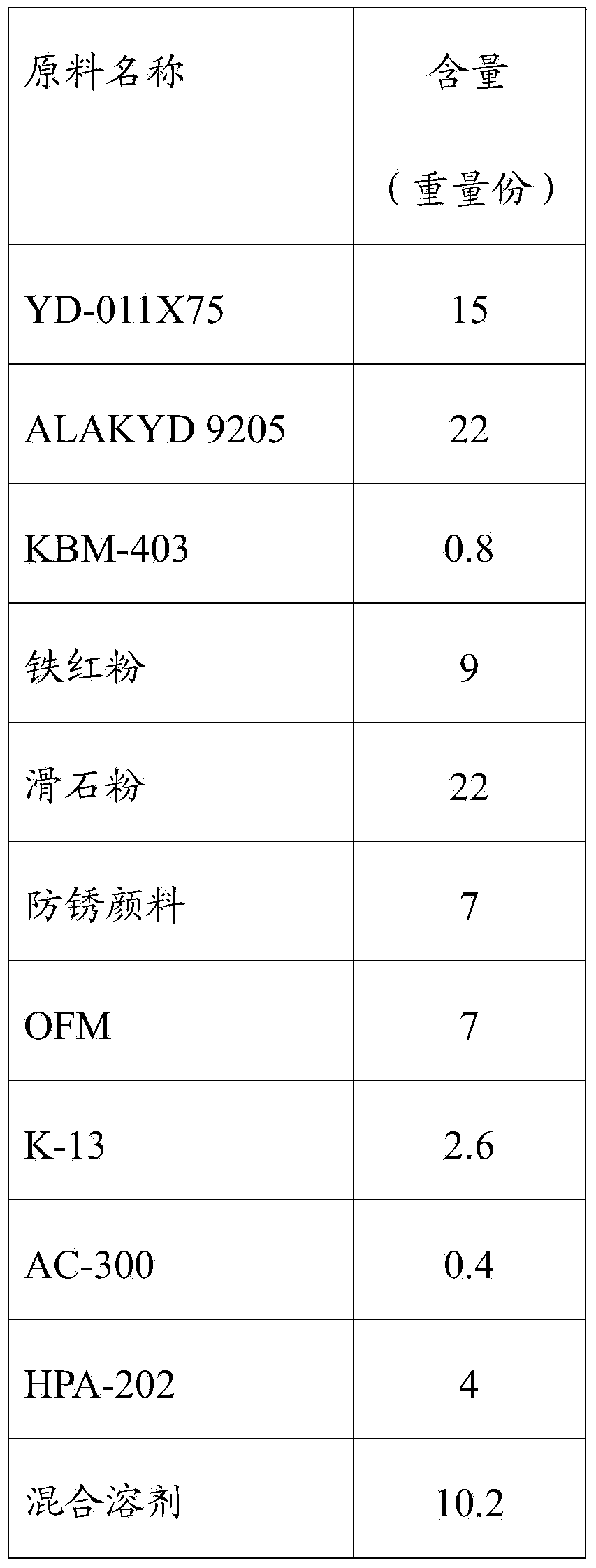

Embodiment 2

[0029] raw material name

[0030]

[0031] The preparation method is: put 14 parts by weight of epoxy resin (YD011X75), 24 parts of high molecular weight epoxy resin (ALAKYD9205), and 0.7 parts by weight of silane coupling agent (KBM403) into the dispersion kettle, stir evenly, and then Add the following components respectively: 10 parts by weight of iron red powder, 23 parts by weight of talcum powder, 6 parts by weight of antirust pigment, 6 parts by weight of dehydrating agent (OFM) and some solvents, disperse at high speed for 30 minutes, and then use sand mill grinder or three-roll mill to standard fineness, add 2 parts by weight of ketimine, 0.3 parts by weight of antifoaming agent (AC-300) and 3 parts by weight of thixotropic agent (HPA202) under low-speed stirring, and mix After uniformity, filter and seal the package.

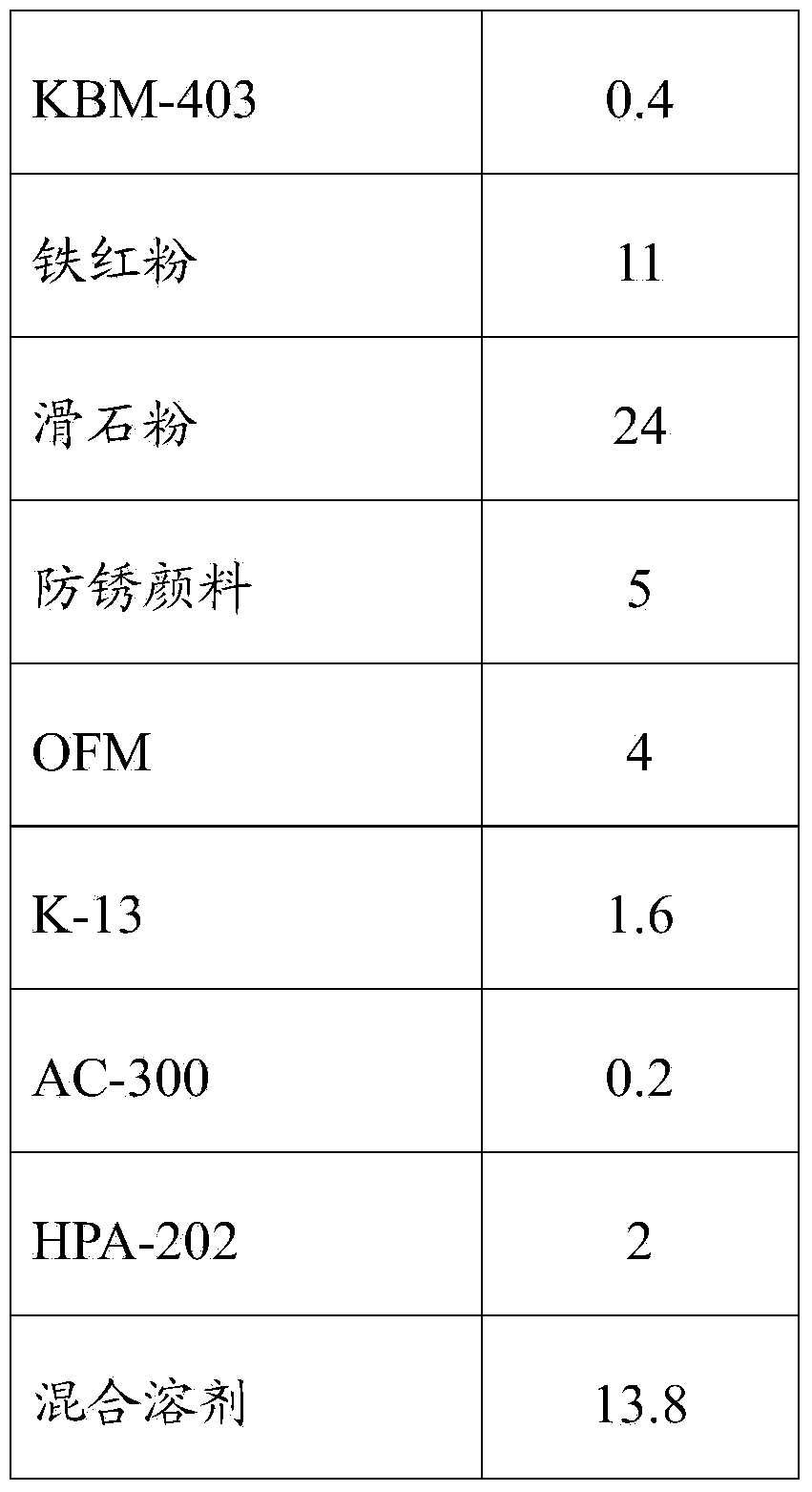

Embodiment 3

[0033]

[0034] The preparation method is as follows: put 15 parts by weight of epoxy resin (YD011X75), 22 parts of high molecular weight epoxy resin (ALAKYD9205), and 0.8 parts by weight of silane coupling agent (KBM403) into the dispersion kettle, stir evenly, and start stirring Add the following components respectively: 9 parts by weight of iron red powder, 22 parts by weight of talcum powder, 7 parts by weight of antirust pigment, 7 parts by weight of dehydrating agent (OFM) and some solvents, disperse at high speed for 30 minutes, and then use sand mill grinder or three-roll mill to standard fineness, put 2.6 parts by weight of ketimine, 0.4 parts by weight of antifoaming agent (AC-300) and 4 parts by weight of thixotropic agent (HPA202) under low-speed stirring, and mix After uniformity, filter and seal the package.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com