Pickle zymocyte microbial inoculum, and preparation method and application thereof

A technology of fermenting bacteria and bacterial preparations, which is applied in the field of kimchi fermentation bacterial preparations and preparations, can solve the problems of unstable product quality, long kimchi fermentation cycle, and difficult rectal colonization, so as to reduce the risk of coronary heart disease and highlight health care Function, the effect of preventing excessive absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

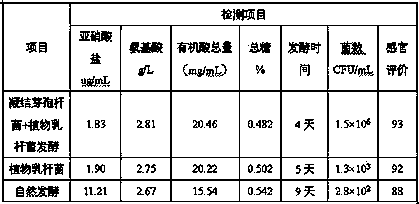

Examples

Embodiment 1

[0030] (1) Preparation of starter: Bacillus coagulans and Lactobacillus plantarum were value-added cultured in MRS liquid medium at 30°C for 18-22h, respectively, and centrifuged at 4000r / min and 4°C for 15min to collect the bacteria , with a ratio of 1:2, the total amount of mixed bacteria is 2×10 7 CFU, with 8 parts of skimmed milk powder, 8 parts of maltose, 8 parts of sodium glutamate, and 100 parts of sterile water as a combined protective agent, pre-freeze at -80°C for 2 hours, and transfer the sample to a freeze dryer immediately after it is completely frozen freeze-dried for 24 hours. Different rotation speed, temperature and time mainly affect the survival rate; determine the optimal rotation speed, temperature and time during concentration to ensure the survival rate of strain collection.

[0031]Vacuum freeze-drying is to first freeze the bacterial suspension in a low temperature environment lower than the triple point, and then vacuumize, the free water inside and...

Embodiment 2

[0039] (1) Preparation of starter: Inoculate the preserved Bacillus coagulans and Lactobacillus plantarum strains in MRS liquid medium to activate the third-generation microscopic examination without impurities, then transfer them to new MRS medium and cultivate them for 12h-18h, so that Bacteria concentration reached 10 7 At the order of individual / mL, store in a 4°C refrigerator for later use.

[0040] (2) Bacillus coagulans and Lactobacillus plantarum were centrifuged at 4000r / min and 3°C for 20 minutes to collect the bacteria, and the bacteria were mixed at a ratio of 1:1, and the total bacteria volume was 1×10 7 CFU, with 6 parts of skimmed milk powder, 5 parts of maltose, 5 parts of sodium glutamate, and 90 parts of sterile water as a combined protective agent, pre-freeze at -90°C for 1 hour, and transfer the sample to a freeze dryer immediately after it is completely frozen freeze-dried for 25 hours.

[0041] (2) The technological process of inoculating fermented kimc...

Embodiment 3

[0046] Strain growth and cell collection: Inoculate the strains in MRS liquid medium with 5% inoculation amount, and cultivate them at 30°C for 18-22 hours, so that Bacillus coagulans and Lactobacillus plantarum are in a stable growth period, and wait for the microscope After checking that there is no miscellaneous bacteria, put equal amounts into 15mL sterile centrifuge tubes, centrifuge at 4000r / min for 15min at 4°C, discard the supernatant to collect the bacteria, and the total mixed bacteria volume is 1.52×10 7 CFU. Preparation of protective agent: Weigh 7.06 parts of skimmed milk powder, 6.46 parts of maltose, and 6.70 parts of sodium glutamate in proportion to dissolve them in 100 parts of sterile water test tubes, sterilize them respectively, and mix well to make a compound protective agent. Among them, the sodium glutamate and maltose protective agent solution were sterilized by filtration with a filter membrane with a pore size of 0.22 μm, and the skimmed milk powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com