Method for producing aluminum electrolyte by using aluminum electrolysis waste materials and recycling carbon

An aluminum electrolysis and electrolyte technology, applied in the field of waste resource recycling, can solve the problems of unutilized valuable elements, high environmental risk of landfill method, unqualified product quality of flotation method, etc., and achieves less harmful impurities and moisture content low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

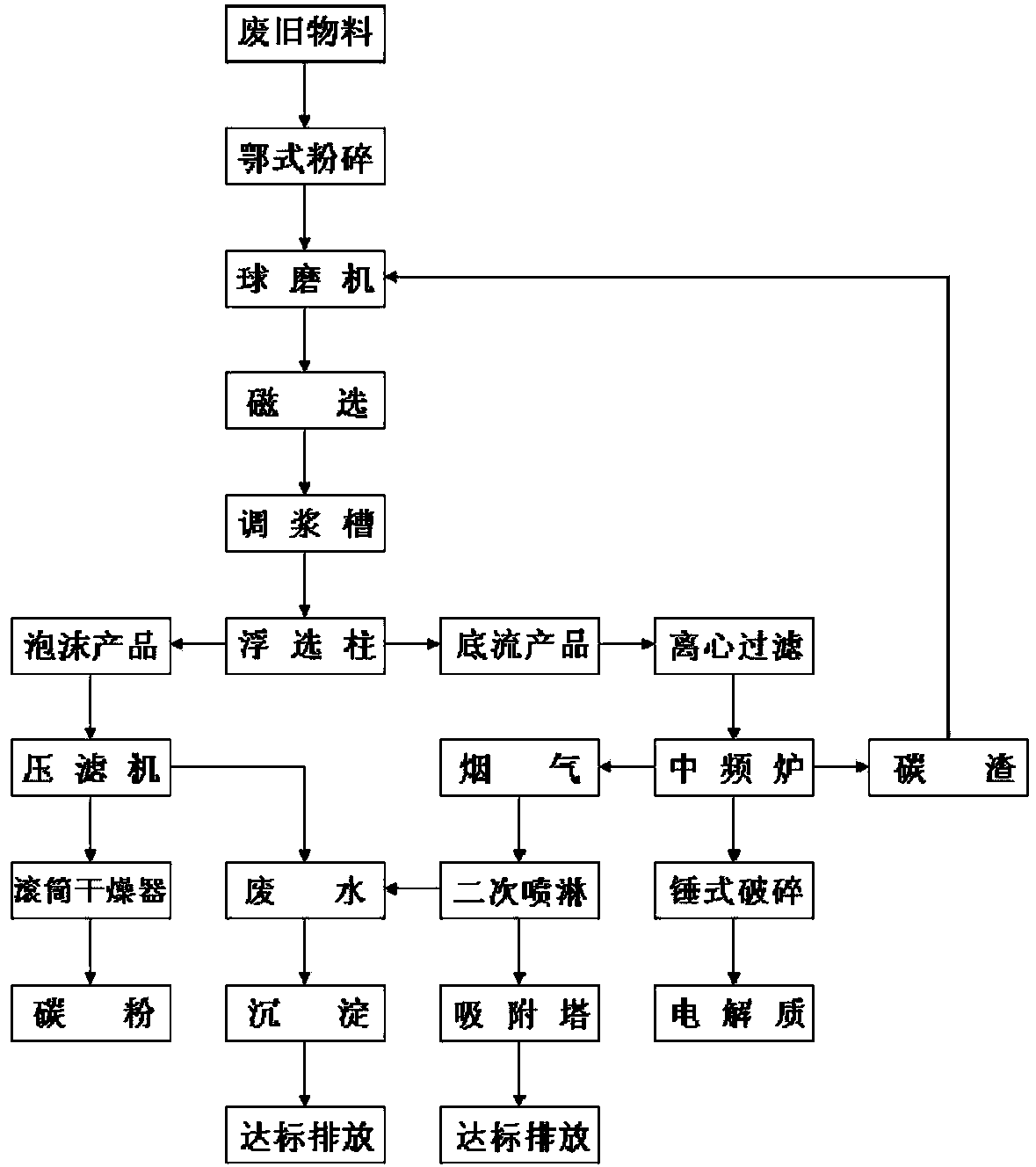

Image

Examples

Embodiment 1

[0038] Put 100Kg of raw material electrolysis waste cathode carbon blocks into a jaw crusher for crushing, and then into a ball mill for crushing through an 80-150 mesh sieve, add 2Kg of diesel oil, coal flotation GF oil 0.6Kg, and enter the micro-bubble countercurrent flotation column to separate to obtain an underflow product 30Kg and foam product 70Kg, the underflow product is centrifugally filtered, and carbon is removed by an intermediate frequency furnace. The foam product is filtered and dried to obtain the target carbon powder 69.5Kg. The flue gas generated during the preparation process is first absorbed by the second spraying absorption tower, and then discharged through the activated alumina adsorption tower. The waste water is recycled through precipitation and discharged up to the standard. The main component of the slag produced by the treatment is CaF 2 , can be used as fluorite.

[0039] After testing, the carbon content of the electrolyte is 1.5%, the fix...

Embodiment 2

[0041]Put 100 Kg of raw material electrolysis waste cathode carbon blocks into a jaw crusher for crushing, and then into a ball mill for crushing through an 80-150 mesh sieve, add 2.1Kg of diesel oil, coal flotation 0.7Kg of GF oil, and enter the micro-bubble countercurrent flotation column for separation to obtain The underflow product is 33Kg and the foam product is 67Kg. The underflow product is centrifugally filtered and decarbonized by an intermediate frequency furnace. The separated foam product was filtered and dried to obtain 66.5Kg of target carbon powder. The flue gas generated during the preparation process is first absorbed by the second spraying absorption tower, and then discharged through the activated alumina adsorption tower. The waste water is recycled through precipitation and discharged up to the standard. The main component of the slag produced by the treatment is CaF 2 , can be used as fluorite.

[0042] After testing, the carbon content of the electroly...

Embodiment 3

[0044] Put 100Kg of raw material electrolysis waste cathode carbon blocks into a jaw crusher for crushing, and then into a ball mill for crushing through a 80-150 mesh sieve, add 2.2Kg of diesel oil, coal flotation GF oil 0.8Kg, and enter the micro-bubble countercurrent flotation column to separate to obtain an underflow The product is 32Kg and the foam product is 68Kg. The underflow product is centrifugally filtered, and the intermediate frequency furnace is used to remove carbon. The power of the intermediate frequency induction furnace is controlled at 350KW. The obtained foam product was press-filtered and dried to obtain 67.5 kg of target carbon powder. The flue gas generated during the preparation process is first absorbed by the second spraying absorption tower, and then discharged through the activated alumina adsorption tower. The waste water is recycled through precipitation and discharged up to the standard. The main component of the slag produced by the treatment is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com