Self-healing bulletproof composite material

A composite structure and thin-film material technology, which is applied in the direction of protective equipment, offensive equipment, layered products, etc., can solve problems such as the brittleness of ceramic materials, and achieve the effects of improving protective performance, reducing difficulty, and reducing expensive costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

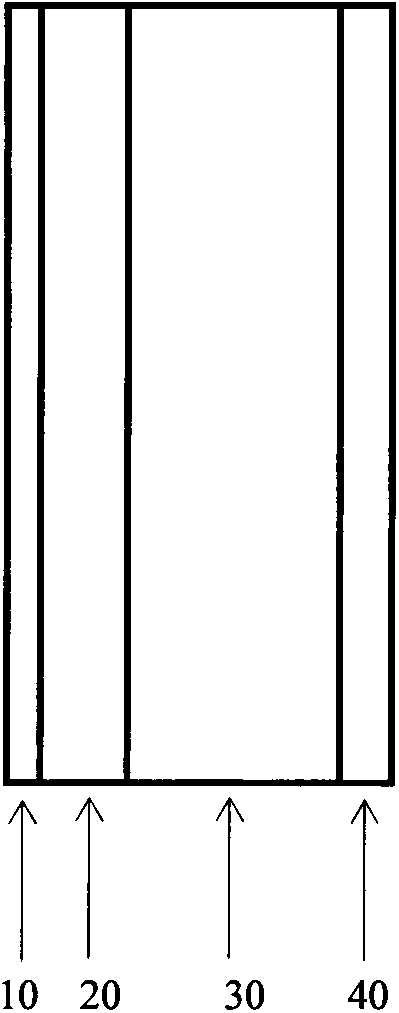

[0013] The surface layer 10 is a 1mm thick neoprene cloth with a surface density of 0.14g / cm 2 ; The rubber layer 20 is 4mm natural rubber, and the surface density is 0.46g / cm 2 ; The ceramic layer 30 is a corundum ceramic column with a height of 18mm, the two ends are hemispherical, and the surface density is 5.24g / cm 2 ; The resistance layer 40 is a 2mm thick TC4 titanium alloy plate with a surface density of 0.89g / cm 2 . After compounding, the surface density of the whole board is 6.7~6.9g / cm 2 , that is, 67~69Kg / m 2 , the thickness of the whole board is 25 ~ 26mm, the whole board is a square flat plate, the length and width are 150mm.

Embodiment 2

[0015] The anti-caving layer 10 is a 2mm thick polycarbonate plate with a surface density of 0.1g / cm2; the rubber layer 20 is a 3mm non-vulcanized rubber with a surface density of 0.34g / cm2; the ceramic layer 30 is a 16mm thick boron carbide plate with a surface density of 3.82 g / cm2; the resistance layer 40 is a 3mm thick carbon fiber composite material plate with a surface density of 0.2g / cm2. After compounding, the surface density of the whole board is 4.4-4.8g / cm2, that is, 44-48Kg / m2, the thickness of the whole board is 24-26mm, and the whole board is a square flat plate with a length and width of 150mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com