Nanograde biocomposite and applications thereof

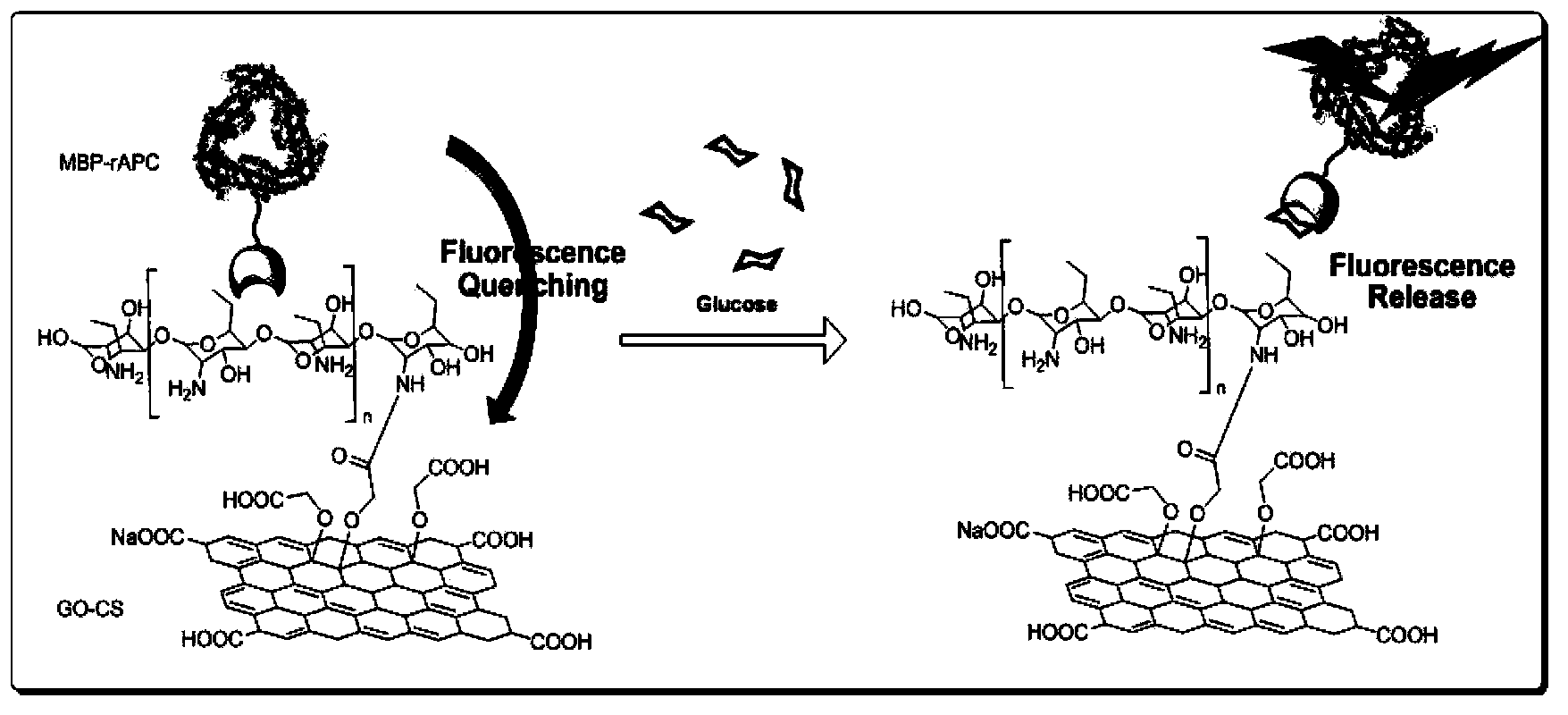

A nano-scale, complex technology, applied in the biological field, can solve the problems of low sensor production reproducibility, irreversible sensor signal, weak storage stability, etc., and achieve the effects of easy detection, high production reproducibility, and high biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

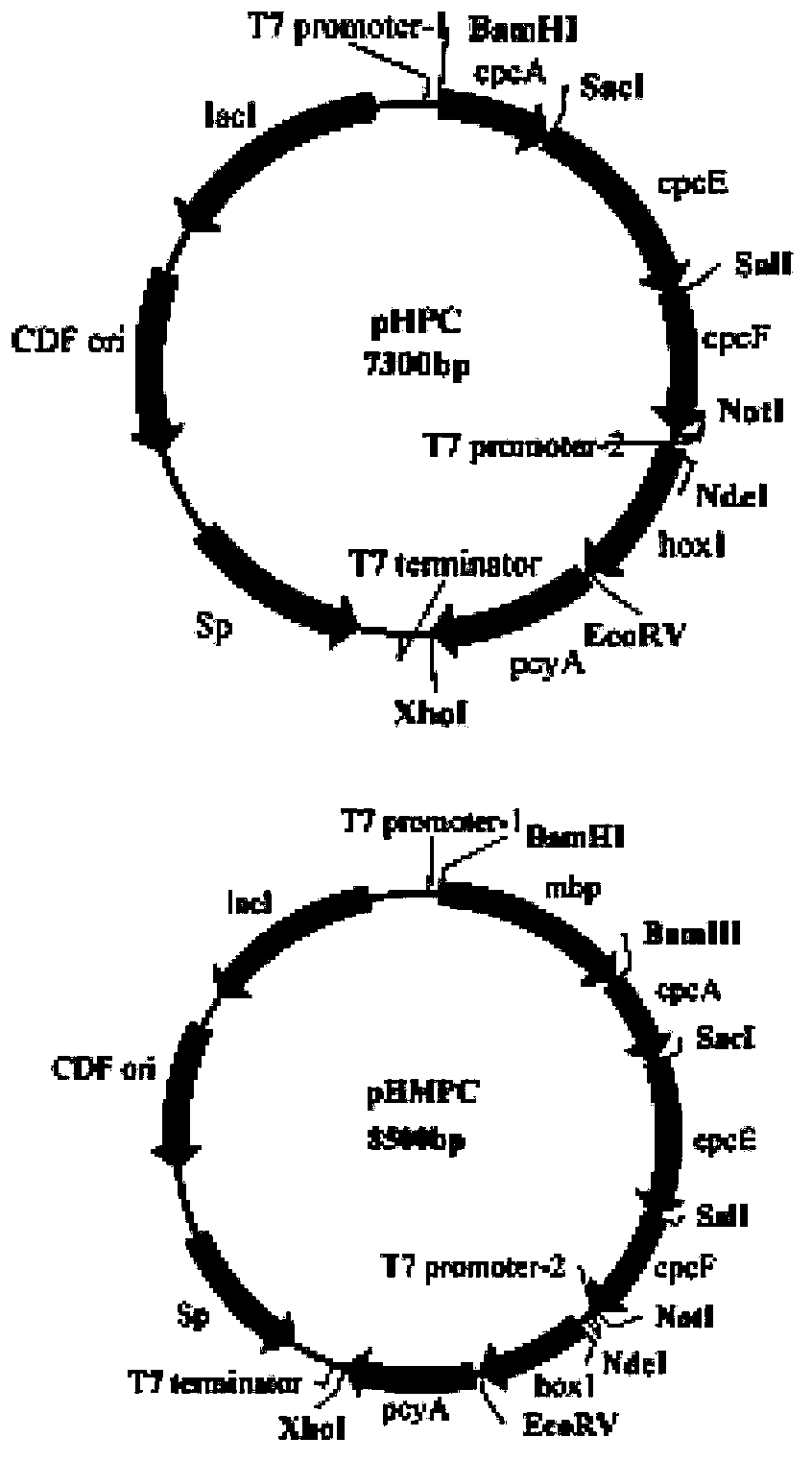

[0029] Synthesis of nanoscale biocomplexes:

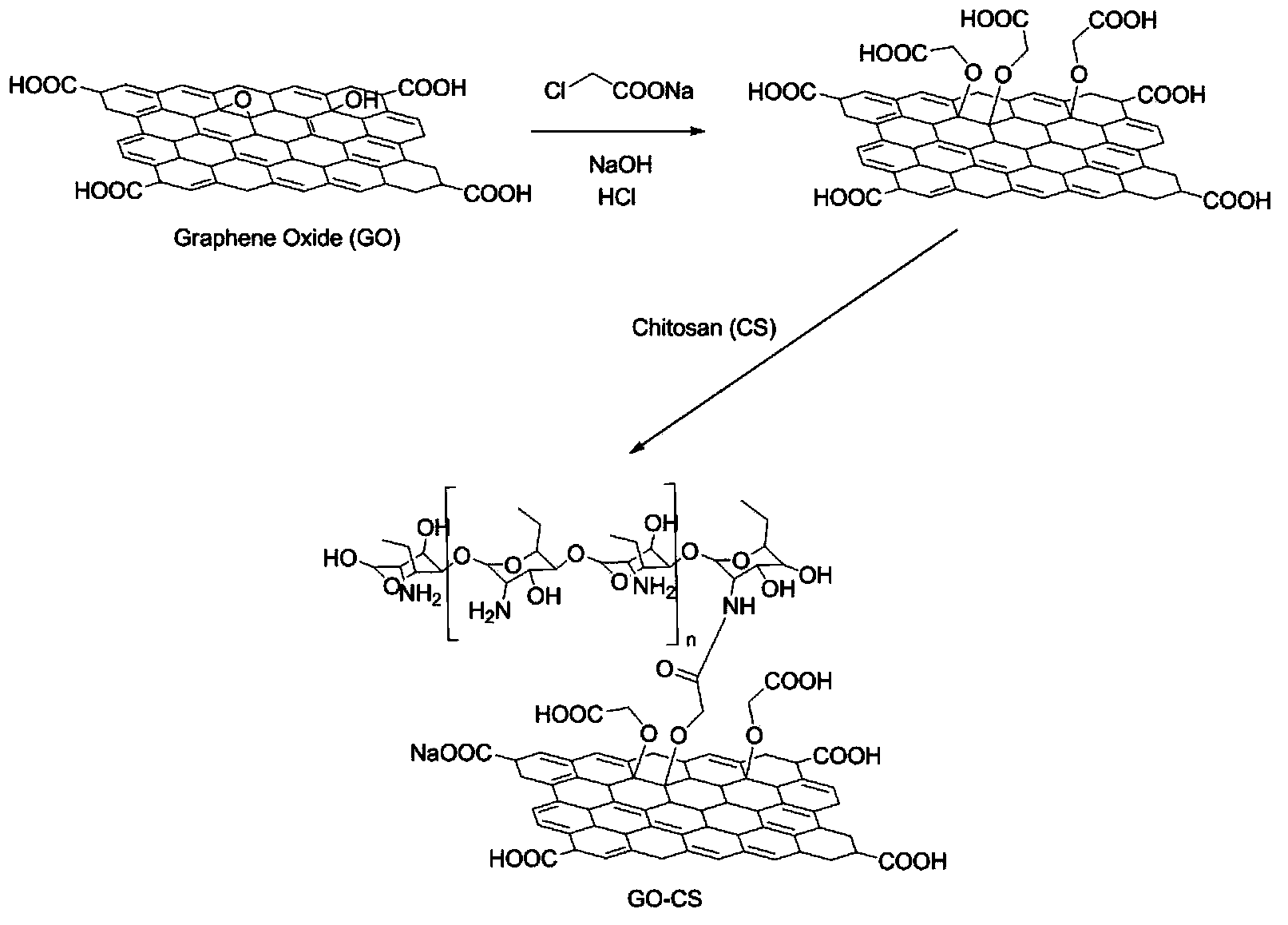

[0030] 1) Synthesis of graphene oxide-low molecular weight chitosan composite:

[0031] Mix 2 g of flake graphite with 1.5 ml of pure sulfuric acid, 0.8 g of potassium persulfate and 0.5 g of phosphorus pentoxide, and incubate at 80°C for 6 hours after mixing to obtain pre-oxidized graphite.

[0032] The pre-oxidized graphite powder was washed with distilled water until neutral, filtered and dried in air overnight at room temperature. Take 1 g of pre-oxidized graphite powder and place it in 29 ml of pure sulfuric acid at 0°C. Then keep the temperature below 20°C, gradually add 3 grams of potassium permanganate while stirring, then stir the mixture below 35°C for 2 hours, add 46 ml of distilled water after stirring, and continue stirring for 15 minutes. Finally, 140 ml of distilled water was added to terminate the reaction, followed by the addition of 2 ml of 30% hydrogen peroxide to turn the color of the mixture into bright yello...

Embodiment 2

[0042] Synthesis of Graphene Oxide-Low Molecular Weight Chitosan Composite

[0043] 1) 3g of flake graphite will be mixed with 2.0ml of pure sulfuric acid, 0.8g of potassium persulfate, and 0.8g of phosphorus pentoxide, and then incubated at 80 degrees for 7 hours to pre-oxidize the graphite. Then the product was washed with distilled water to neutrality, filtered and dried in air overnight at room temperature. 2g of pre-oxidized graphite powder was placed in 30ml of pure sulfuric acid at 0°C. Keep the temperature below 20 degrees, gradually add 5 grams of potassium permanganate while stirring, then stir the mixture below 35 degrees for 3 hours, then add 60 ml of distilled water, and continue to stir for 25 minutes. Then 200 ml of distilled water was added to stop the reaction, followed by 5 ml of 30% hydrogen peroxide to turn the color of the mixture into bright yellow. The mixture was centrifuged and washed with 300 mL of 10% HCl solution to remove residual metal ions. The...

Embodiment 3

[0047] The difference from Example 1 is:

[0048] Mix 8 g of flake graphite with 8 ml of pure sulfuric acid, 8 g of potassium persulfate and 5 g of phosphorus pentoxide, and incubate at 80°C for 10 hours after mixing to obtain pre-oxidized graphite. The pre-oxidized graphite powder was washed with distilled water until neutral, filtered and dried in air overnight at room temperature. Take 1g of pre-oxidized graphite powder and place it in 90ml of pure sulfuric acid at 0°C. Then keep the temperature below 20°C, gradually add 30 grams of potassium permanganate while stirring, then stir the mixture below 35°C for 5 hours, add 460 ml of distilled water after stirring, and continue stirring for 15 minutes. Finally, 400 ml of distilled water was added to terminate the reaction, followed by the addition of 20 ml of 30% hydrogen peroxide to turn the color of the mixture into bright yellow. Centrifuge the above-mentioned mixture that turns bright yellow, and wash the precipitate with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com