Forging forming method for magnesium alloy rings

A magnesium alloy and ring technology, applied in the field of magnesium alloy processing, can solve problems such as easy cracking in forging and complex forming process of magnesium alloy rings, and achieve the effects of less equipment investment, excellent mechanical properties, and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

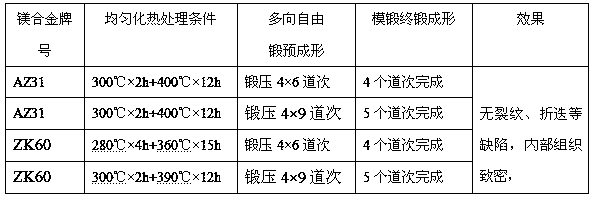

[0017] Example 1 : the magnesium alloy that present embodiment selects is the AZ31 ingot of semi-continuous casting, and the forging forming of ring comprises the following steps:

[0018] 1) Cutting: Saw the AZ31 magnesium alloy ingot and cut it into cube blocks. The size of the block is determined according to the size of the ring and the principle of constant volume. The height / side ratio of the cube is 1.1.

[0019] 2) Billet homogenization heat treatment: put the AZ31 magnesium alloy billet in a resistance furnace for homogenization heat treatment, adopt a two-stage homogenization heat treatment system, that is, 300°C×2h+400°C×12h, to eliminate casting segregation as much as possible, and make the microstructure Uniform; air cool to room temperature after homogenization.

[0020] 3) Pretreatment of blanks and molds before forging, including:

[0021] a. Surface lubrication: Coating graphite lubricant on the surface of the mold cavity and the surface of the billet, the g...

Embodiment 2

[0026] Example 2: The magnesium alloy selected in this embodiment is the AZ31 ingot of semi-continuous casting, and the forging forming of the ring comprises the following steps:

[0027] 1) Cutting: Saw the AZ31 magnesium alloy ingot and cut it into cube blocks. The size of the block is determined according to the size of the ring and the principle of constant volume. The height / side ratio of the cube is 1.02.

[0028] 2) Billet homogenization heat treatment: put the AZ31 magnesium alloy billet in a resistance furnace for homogenization heat treatment, adopt a two-stage homogenization heat treatment system, that is, 300°C×2h+400°C×12h, to eliminate casting segregation as much as possible, and make the microstructure Uniform; air cool to room temperature after homogenization.

[0029] 3) Pretreatment of blanks and molds before forging, including:

[0030] a. Surface lubrication: Coating graphite lubricant on the surface of the mold cavity and the surface of the billet, the ...

Embodiment 3

[0035] Example 3 : the magnesium alloy that present embodiment selects is the AZ31 ingot of semi-continuous casting, and the forging forming of ring comprises the following steps:

[0036] 1) Cutting: Saw the AZ31 magnesium alloy ingot and cut it into cube blocks. The size of the block is determined according to the size of the ring and the principle of constant volume. The height / side ratio of the cube is 0.9.

[0037] 2) Billet homogenization heat treatment: put the AZ31 magnesium alloy billet in a resistance furnace for homogenization heat treatment, adopt a two-stage homogenization heat treatment system, that is, 300°C×2h+400°C×12h, to eliminate casting segregation as much as possible, and make the microstructure Uniform; air cool to room temperature after homogenization.

[0038] 3) Pretreatment of blanks and molds before forging, including:

[0039] a. Surface lubrication: Coating graphite lubricant on the surface of the mold cavity and the surface of the billet, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com