Composite lining for corrosion prevention of dissolution tank

A composite lining and corrosion protection technology, applied in the direction of layered products, metal layered products, chemical instruments and methods, etc., can solve problems such as single, difficult to ensure stable and continuous production, and achieve the goal of reducing corrosion and reducing the probability of harm Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

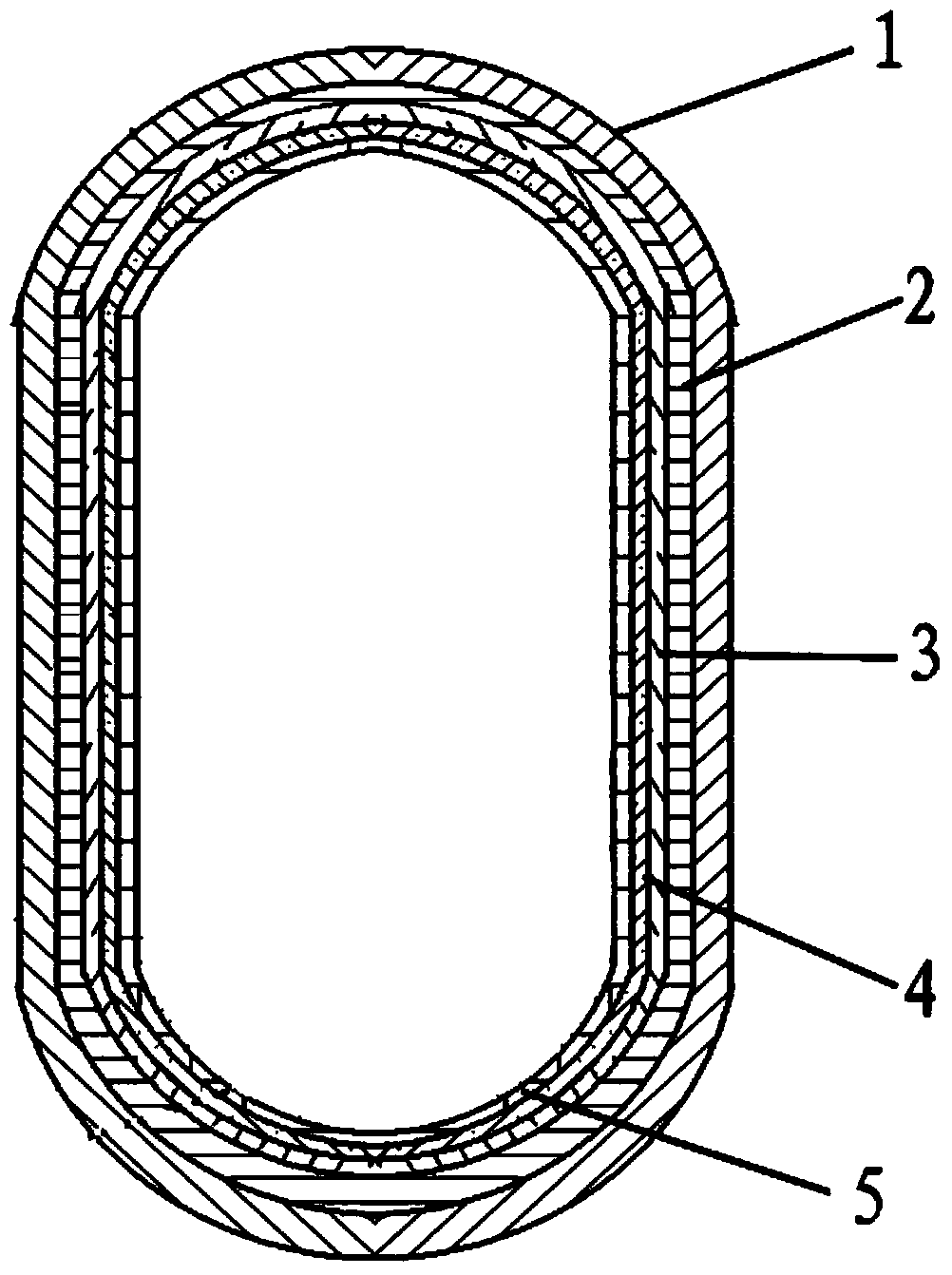

[0025] 1) Prepare the metal layer: such as figure 1 As shown, first clean the surface of the steel substrate of the dissolution lining, specifically, first clean the surface of the sample with acetone, and then use 30 mesh brown corundum to pre-treat the sample by sandblasting. After the sandblasting is completed, use clean compressed air Blow off the dust and debris on the surface; after cleaning, use the DPT2303 type arc spraying device to spray the aluminum metal layer 2 on the steel substrate surface of the dissolution lining. The parameters of the spraying are: voltage 30V ~ 32V, current 140A ~ 160A, air pressure 0.16MPa~0.17MPa, the spray gun is perpendicular to the workpiece, the spraying distance is 200mm, and the spraying thickness is 40-60μm.

[0026] 2) Preparation of sealing layer: Use DPT2303 type arc spraying device to spray sealing layer 3 composed of epoxy resin powder and zinc sheet with a mass ratio of 3:1. The spraying parameters are: voltage 20V-22V, curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com