Low-temperature sealing glass and preparation method thereof

A glass and low-temperature technology, applied in the field of materials, can solve the problems of low operating temperature and high sintering temperature, and achieve the effect of maintaining toughness and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

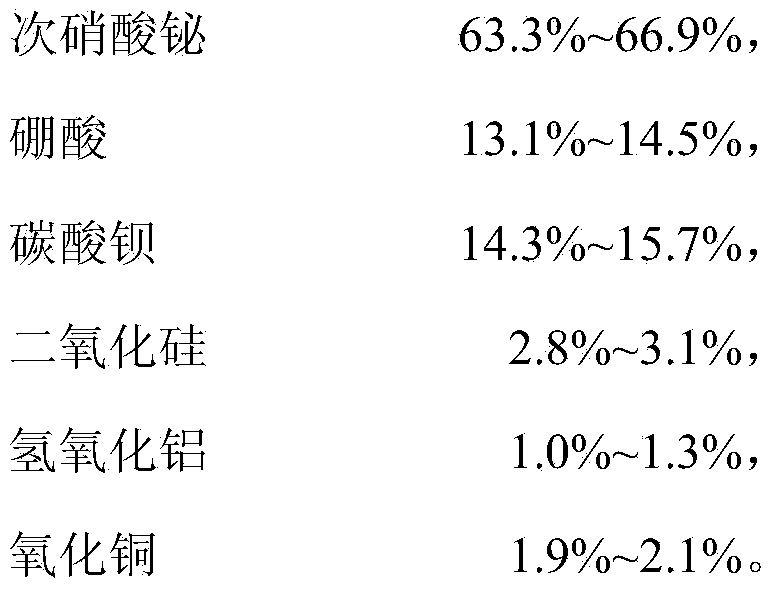

[0021] Embodiment 1: a kind of low-temperature sealing glass, material comprises bismuth subnitrate, boric acid, barium carbonate, silicon dioxide, aluminum hydroxide and copper oxide, and surplus is unavoidable impurity, and its composition is by weight percentage:

[0022]

[0023]

[0024] The preparation method of above-mentioned low-temperature sealing glass is:

[0025] Step 1: Weigh bismuth nitrate, boric acid, barium carbonate, silicon dioxide, aluminum hydroxide and copper oxide according to the weight percentage and fully mix them uniformly;

[0026] Step 2: Put the mixed raw materials into the crucible, put it in a high-temperature resistance furnace at 1100°C for sintering for 20 minutes, then take out the crucible and cool it for 2 minutes, and quickly put the molten glass body into room temperature water;

[0027] Step 3: After taking it out, put it in a high-temperature box and dry it at 150°C for 1 hour;

[0028] Step 4: Put the vitreous body into a ball...

Embodiment 2

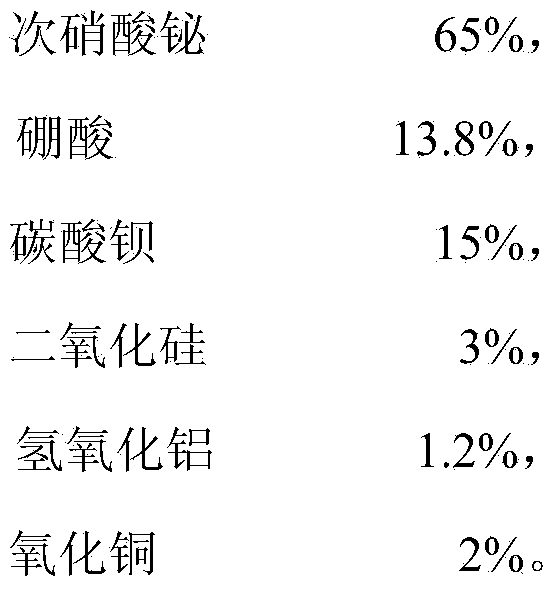

[0033] Embodiment 2: a kind of low-temperature sealing glass, material comprises bismuth subnitrate, boric acid, barium carbonate, silicon dioxide, aluminum hydroxide and copper oxide, and surplus is unavoidable impurity, and its composition is by weight percentage:

[0034]

[0035]

[0036] The preparation method of above-mentioned low-temperature sealing glass is:

[0037] Step 1: Weigh bismuth nitrate, boric acid, barium carbonate, silicon dioxide, aluminum hydroxide and copper oxide according to the weight percentage and fully mix them uniformly;

[0038] Step 2: Put the mixed raw materials into the crucible. The crucible is a bisque crucible, put it in a high-temperature resistance furnace at 1150°C for sintering for 15 minutes, then take out the crucible and cool it for 1 minute, and quickly put the molten glass body into room temperature water;

[0039] Step 3: After taking it out, put it in a high-temperature box and dry it at 150°C for 1 hour;

[0040] Step 4:...

Embodiment 3

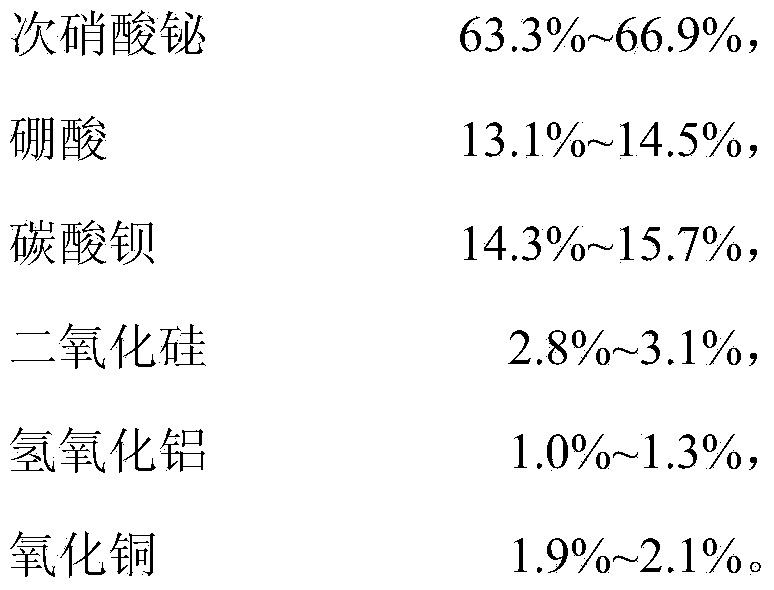

[0045] Embodiment 3: a kind of low-temperature sealing glass, material comprises bismuth subnitrate, boric acid, barium carbonate, silicon dioxide, aluminum hydroxide and copper oxide, and surplus is unavoidable impurity, and its composition is by weight percentage:

[0046]

[0047] The preparation method of above-mentioned low-temperature sealing glass is:

[0048] Step 1: Weigh bismuth nitrate, boric acid, barium carbonate, silicon dioxide, aluminum hydroxide and copper oxide according to the weight percentage and fully mix them uniformly;

[0049] Step 2: Put the mixed raw materials into a bisque crucible, put it in a high-temperature resistance furnace at 1120°C for sintering for 18 minutes, then take out the crucible to cool for 1.5 minutes, and quickly put the molten glass body into room temperature water;

[0050] Step 3: After taking it out, put it in a high-temperature box and dry it at 150°C for 1 hour;

[0051] Step 4: Put the vitreous body into a ball mill cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com