Silicon carbide ceramic thermocouple protection tube and preparation method thereof

A silicon carbide ceramic and thermocouple technology, applied in the field of engineering ceramic materials, can solve the problems of complex structure, uneven drying shrinkage, and key technical data not yet disclosed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0097] A second aspect of the present invention provides a method for preparing the silicon carbide ceramic thermocouple protection tube, which includes the following steps:

[0098] Provide the raw material described in the present invention;

[0099] The raw material is extruded to obtain a tube body of a silicon carbide ceramic thermocouple protection tube;

[0100] The tube body is sintered at a high temperature to obtain the silicon carbide ceramic thermocouple protection tube.

[0101] mold

[0102] The third aspect of the present invention provides a mold for extrusion molding of a ceramic thermocouple protection tube, the mold has a sealing end.

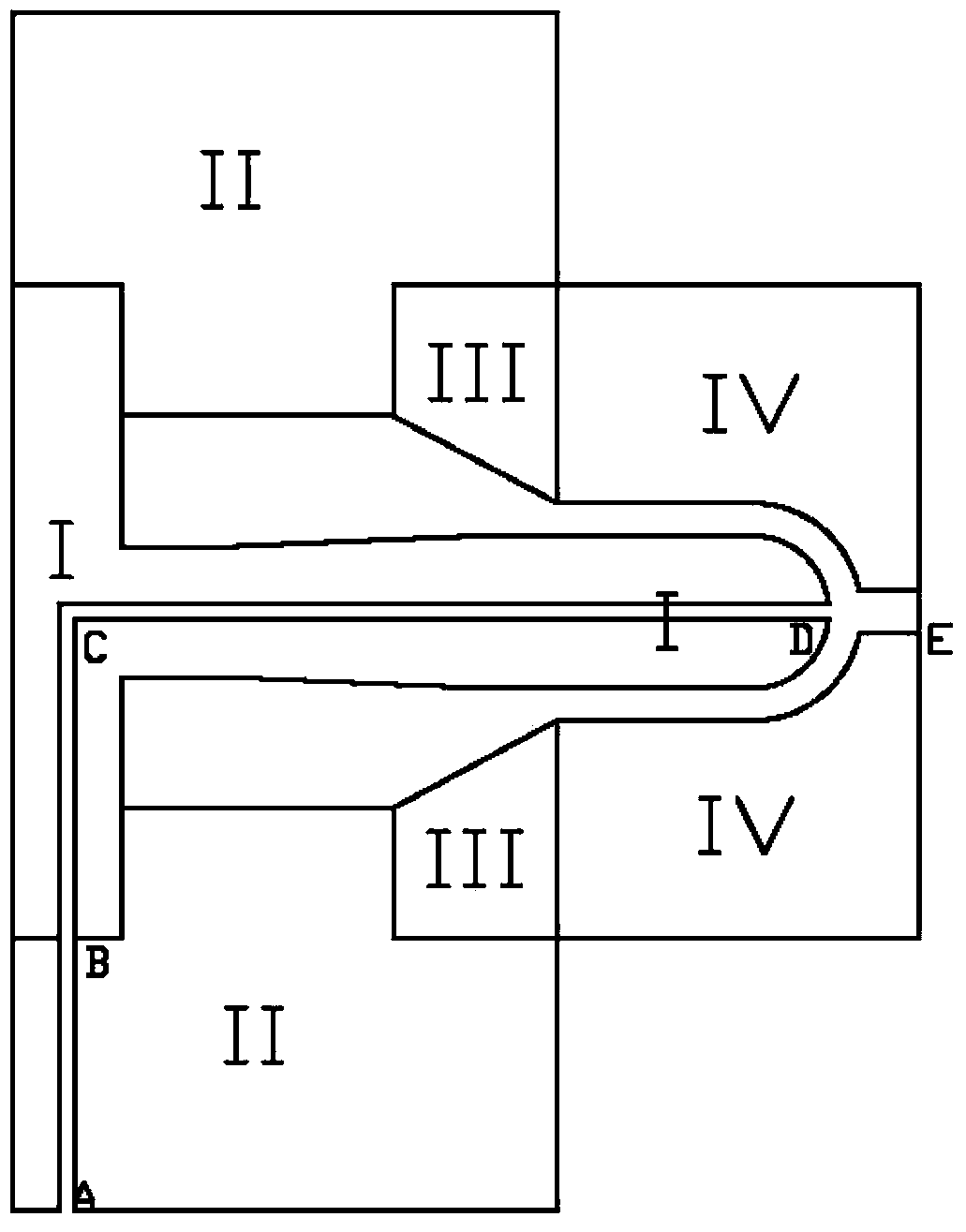

[0103] In a specific embodiment of the present invention, the extrusion sealing mold is mainly composed of (I) extrusion core, (II) connecting piece, (III) outer mold sleeve, and (IV) sealing piece.

[0104] In a specific embodiment, the extrusion core (I) has air holes in the middle of the horizontal and vertical directio...

Embodiment approach

[0115] The method includes process steps such as batching, extrusion molding, drying, heat treatment and high-temperature sintering:

[0116] (1) Mix the silicon carbide powder, the second phase powder and the sintering aid evenly, stir evenly, dry and sieve to obtain the mixed powder.

[0117] The average particle size of the silicon carbide powder can be 0.2-5.0 μm, and the optimized average particle size is 0.5-1.5 μm.

[0118] The second phase powder can be MoSi 2 , BN, TiB 2 , ZrB 2 Or its composite powder, etc., its content is 0-15wt%, and the optimized content is 5-10wt%.

[0119] The sintering aid may include B 4 C-C, C-B system, where C can be introduced in the form of powder or cracking of organic polymers.

[0120] said B 4 The content of C or B is 0-1.5wt%, and the optimized content is 0.4-1.0wt%. The content of C is 0-6wt%, and the optimized content is 1.0-4.0wt%.

[0121] (2) Add plasticizer, water, lubricant, dispersant, defoamer, etc. to the mixed powde...

Embodiment 1

[0146] SiC powder with an average particle size of 0.5 μm and 0.4wt% B 4 C powder and 1.0wt% carbon black are uniformly mixed, stirred evenly, dried and sieved to obtain a mixed powder. Add plasticizer, water, lubricant, dispersant, defoamer, etc. to the mixed powder and stir evenly, and carry out vacuum mud refining in the mixer for aging treatment. Put the mud on the vacuum extruder and install the extrusion die for extrusion molding. When the pipe body is stable, install the sealing piece. Wherein the diameter of the ventilation hole is 0.5 mm, the diameter of the hemispherical plastic plug is 1.5 mm, and the diameter of the mud discharge hole is 1.0 mm. The outer diameter of the extruded pipe is 15mm, the wall thickness is 1.5mm, the surface is smooth, and the sealing is uniform. The extruded silicon carbide thermocouple protection sleeve body is dried and heat-treated at high temperature to obtain silicon carbide ceramics. The density reaches 96.2% T.D, the thermal con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com