A kind of polyester resin for tgic curing high-toughness powder coating and preparation method thereof

A polyester resin and powder coating technology, applied in the field of polyester resin, can solve the problems of difficulty in manufacturing powder coatings and low surface hardness of the coating, and achieve good weather resistance, excellent mechanical properties, excellent flexibility and impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

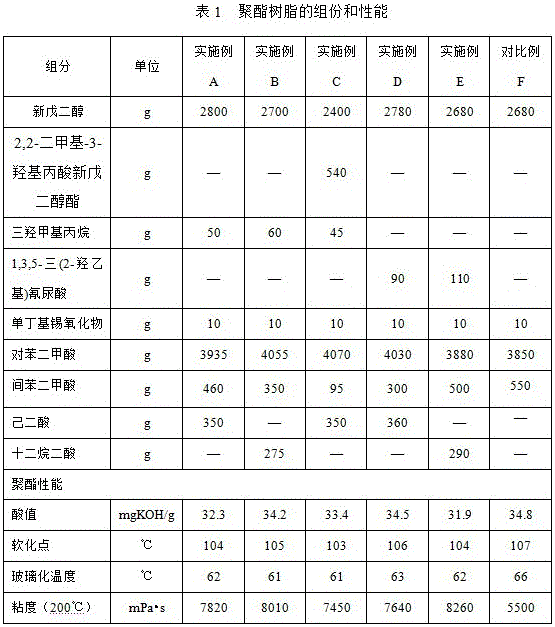

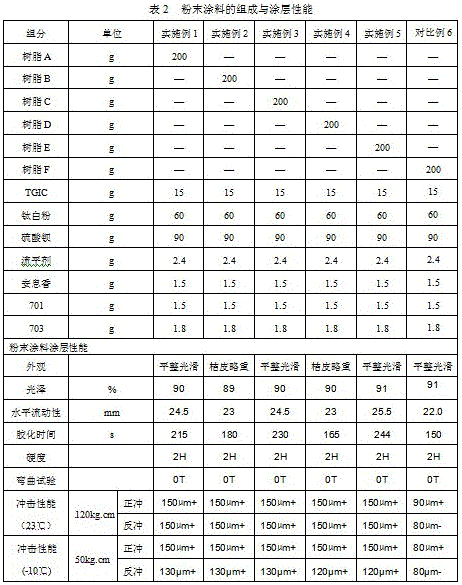

[0017] Some specific examples are enumerated below to illustrate the present invention. Table 1 is an example of polyester resin, and A-E are comparative examples F of different monomers and process combinations. In a 10-liter reactor, add neopentyl glycol, 2,2-dimethyl-3-hydroxypropionate neopentyl glycol, trimethylolpropane, 1,3, 5-tris(2-hydroxyethyl)cyanuric acid, heat up until the material melts; then add terephthalic acid and monobutyltin oxide, and continue to heat up the reaction with nitrogen gas, and esterification water begins to form and distill out at about 180°C, and then Gradually raise the temperature to 250°C, react for 5 to 10 hours until 95% of the esterified water is discharged, and the acid value reaches 10 to 20 mgKOH / g, add acidolysis agents such as isophthalic acid, adipic acid and dodecanedioic acid, After 2-4 hours of reaction, the acid value reaches 40-50 mgKOH / g, and the vacuum polycondensation takes about 2-4 hours, when the acid value reaches 31-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com