Intelligent high-power mechatronic speed adjusting device

A technology of intelligent speed regulation and high power, which is applied in the direction of fluid transmission devices, transmission devices, gear transmission devices, etc., can solve the problems of increased motor loss, large starting current, and troubles in the engineering field of speed regulation technology, so as to reduce shock and vibration , Reduce the starting current, improve the effect of starting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

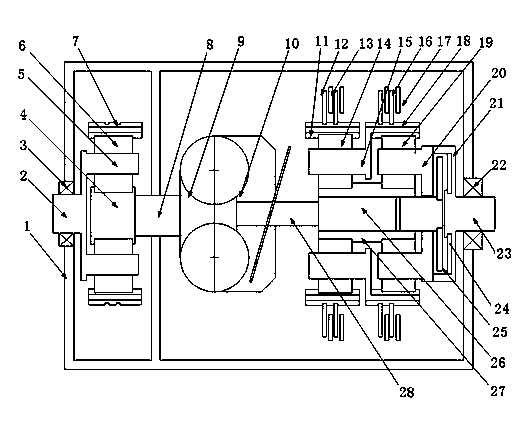

[0016] Such as figure 1 As shown, the present invention includes a casing 1, a speed-regulating fluid coupling arranged in the middle of the casing 1, a front-end planetary speed increaser matched with the input end of the speed-regulating fluid coupling, and a The rear-end planetary transmission connected to the output end; the front-end planetary speed increaser includes a front-end speed-up planetary row, and the output of the front-end speed-up planetary row is matched with the input end of the fluid coupling; the rear-end planetary speed changer includes The first rear-end planetary row and the second rear-end planetary row, the input of the rear-end planetary transmission is matched with the turbine shaft 28 of the fluid coupling; the box body 1 is also provided with two brakes and a clutch and the rear The first rear-end planetary row and the second rear-end planetary row of the end planetary transmission jointly obtain 3 gears; the clutch includes a clutch drum 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com