Laser

A technology of lasers and optical fiber combiners, applied in the field of lasers, can solve the problems of unstable pulsed light output, susceptibility to external environment interference, susceptibility to temperature changes, etc., to achieve stable and efficient optical transmission process, not easy to external environment interference, The effect of increasing optical power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

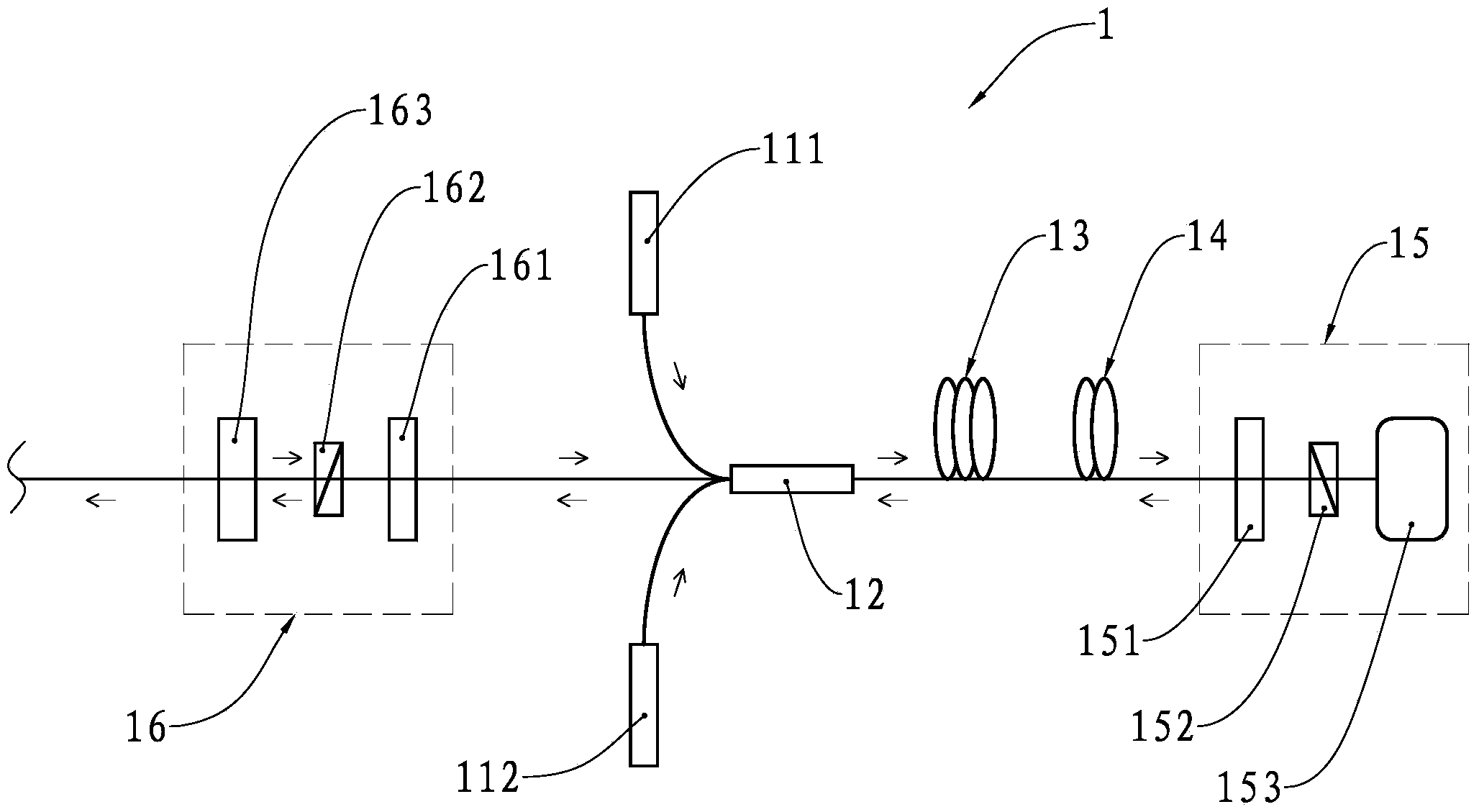

[0031] refer to figure 1 , figure 1 It is a structural diagram of the laser 1 of the present invention. The laser 1 is sequentially provided with a pumping light emitting device 111, a pumping light emitting device 112, a fiber beam combiner 12, a gain fiber 13, a polarization maintaining fiber 14, a resonant cavity 15 and an output cavity 16 in the direction along its optical path, wherein , the resonant cavity 15 is sequentially provided with a collimator 151, a polarization beam splitter 152 and a mode locking device 153 in the direction along the optical path, and the output cavity 16 is provided with a collimator 161, a polarization beam splitter 162 and a output mirror 163 . Preferably, the gain fiber 13 is a double-clad thulium-doped polarization-maintaining fiber, the mode locking device 153 is a semiconductor saturable absorber mirror, and the polarization beam splitting device 152 and polarization beam splitting device 162 are Wollaston prisms or Rochon prisms.

...

no. 2 example

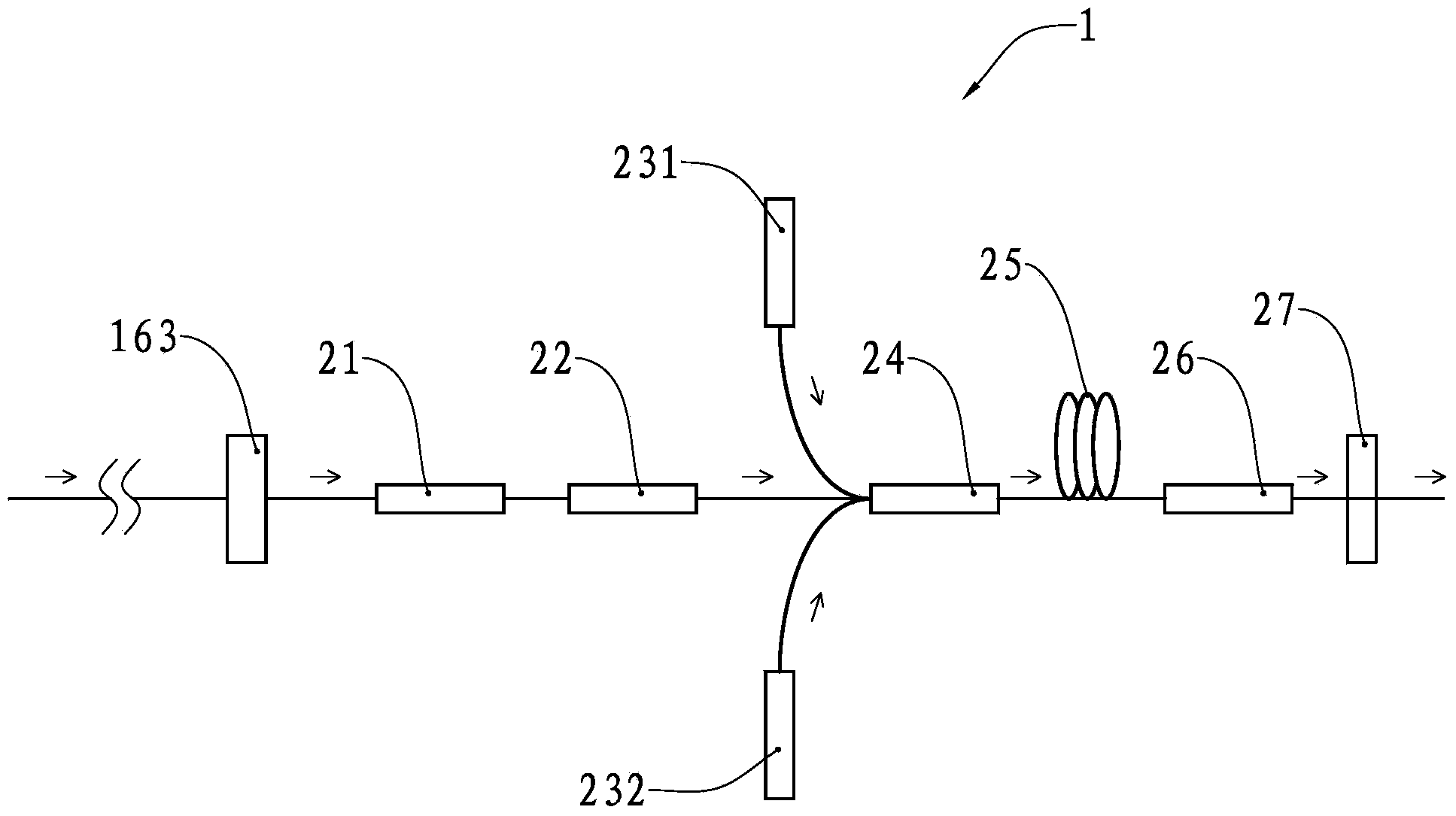

[0038] The laser 1 in this embodiment has a power amplifier, and the power amplifier is located at the output rear stage of the output mirror 163 of the laser 1 in the first embodiment.

[0039] refer to figure 2 , figure 2 It is a structural diagram of the power amplifier of the laser 1. The power amplifier is sequentially provided with an isolator 21, a mode field adapter 22, a pumping light emitting device 231, a pumping light emitting device 232, and a fiber combiner in the direction along its optical path. 24. Gain fiber 25, cladding power stripper 26, collimator 27.

[0040] Collimator 163, isolator 21, mode field adapter 22, pumping light emitting device 231, pumping light emitting device 232, fiber beam combiner 24, gain fiber 25, cladding power stripper 26 and collimator 27 are mutually Both are connected by polarization-maintaining optical fiber.

[0041] After the collimator 163 outputs the mode-locked laser pulse and enters the isolator 21, since the isolator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com