Suckling pig creep feed

A technology of creep feed and suckling pigs, applied in animal feed, animal feed, application, etc., can solve the problems of poor palatability and low digestibility, and achieve the goal of improving digestion and absorption rate, promoting intestinal development, and increasing daily weight gain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

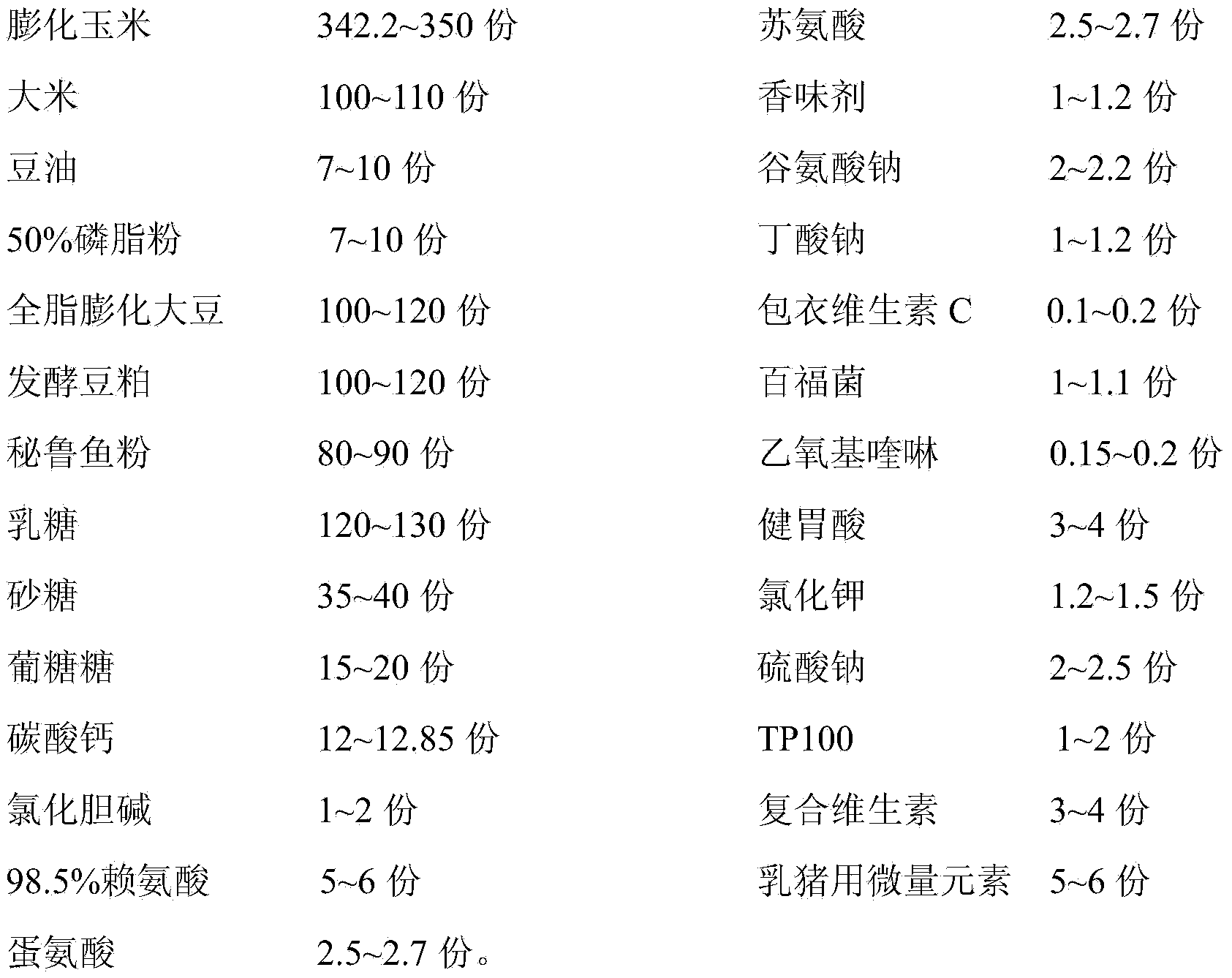

Embodiment 1

[0019] 350 parts of puffed corn, 100 parts of rice, 7 parts of soybean oil, 10 parts of 50% phospholipid powder, 100 parts of full-fat puffed soybean, 120 parts of fermented soybean meal, 80 parts of Peruvian fish meal, 130 parts of lactose, 40 parts of granulated sugar, 15 parts of glucose , 12.85 parts of calcium carbonate, 1 part of choline chloride, 6 parts of 98.5% lysine, 2.7 parts of methionine, 2.7 parts of threonine, 1 part of Ledaxiang, 2 parts of sodium glutamate, 1 part of sodium butyrate, 0.1 part of coated vitamin C, 1 part of Pfaffia, 0.15 part of ethoxyquinoline, 4 parts of gastric acid, 1.5 parts of potassium chloride, 2 parts of sodium sulfate, 1 part of TP100, 3 parts of multivitamins, and trace amounts for suckling pigs Element 5 servings.

[0020] The parts by weight of each component of the multivitamin are: 1 part of vitamin A at 500000IU / g, 30.2 parts of vitamin D at 500000IU / g, 6.5 parts of 50% vitamin E, 30.2 parts of 50% vitamin K, 10.2 parts of vita...

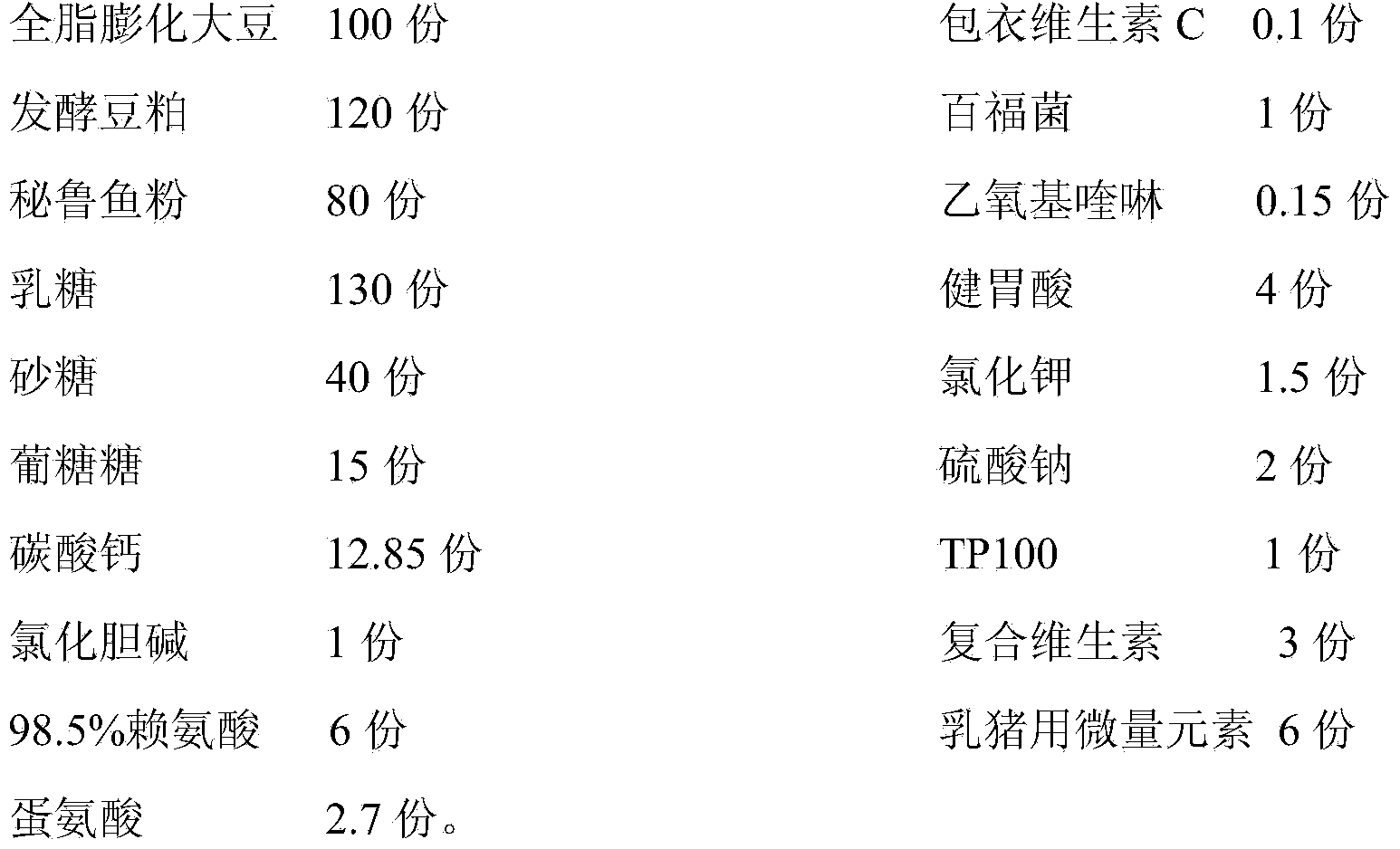

Embodiment 2

[0023] 342.2 parts of puffed corn, 110 parts of rice, 10 parts of soybean oil, 7 parts of 50% phospholipid powder, 120 parts of full-fat puffed soybean, 100 parts of fermented soybean meal, 90 parts of Peruvian fish meal, 120 parts of lactose, 35 parts of granulated sugar, 20 parts of glucose , 12 parts of calcium carbonate, 1 part of choline chloride, 5 parts of 98.5% lysine, 2.5 parts of methionine, 2.5 parts of threonine, 1.2 parts of Le Daxiang, 2.2 parts of sodium glutamate, 1.2 parts of sodium butyrate, 0.2 parts of coated vitamin C, 1.1 parts of Pfaffia, 0.2 parts of ethoxyquinoline, 3 parts of gastric acid, 1.2 parts of potassium chloride, 2.5 parts of sodium sulfate, 1 part of TP1001, 4 parts of multivitamins, and trace amounts for suckling pigs Element 5 servings.

[0024] The parts by weight of each component of the multivitamin are: 1 part of vitamin A at 500000IU / g, 30.2 parts of vitamin D at 500000IU / g, 6.5 parts of 50% vitamin E, 30.2 parts of 50% vitamin K, 10....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com