Nickel or nickel alloy perforated nanosphere and method for manufacturing same

A technology of perforated balls and nickel alloys, applied in the field of metal or alloy powder, can solve the technical problems of difficulty in obtaining powder and other problems, and achieve the effects of improving specific surface, simple and easy process operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

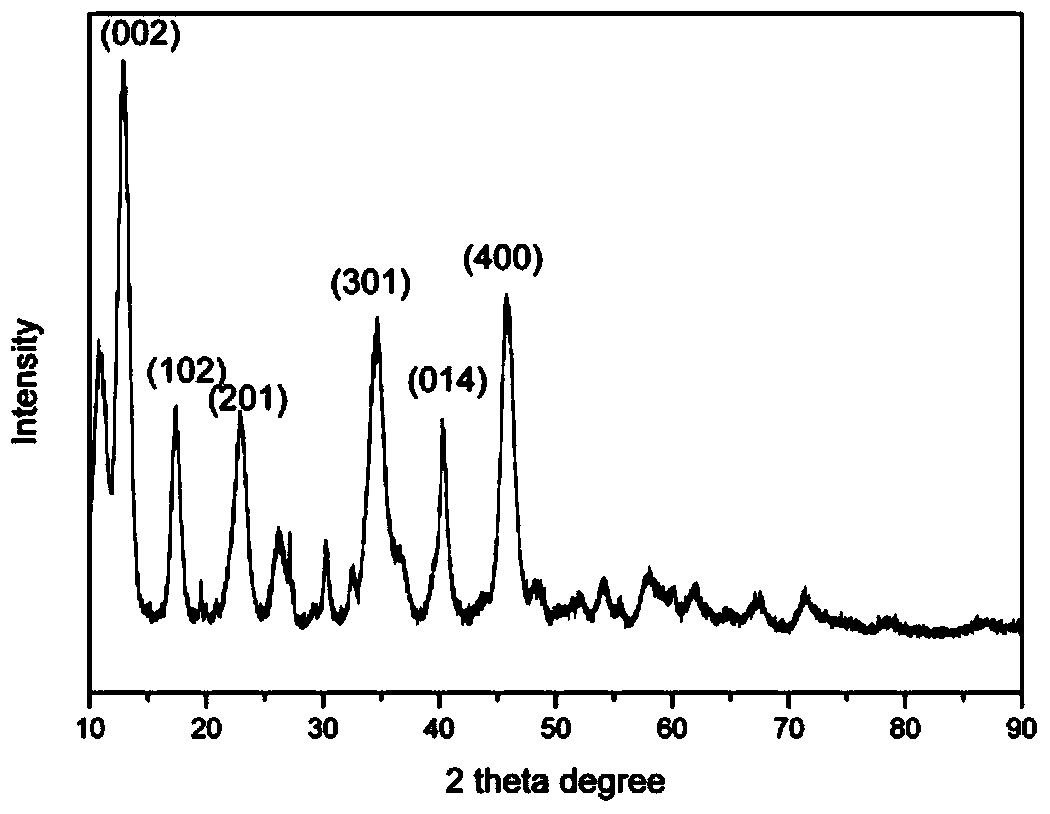

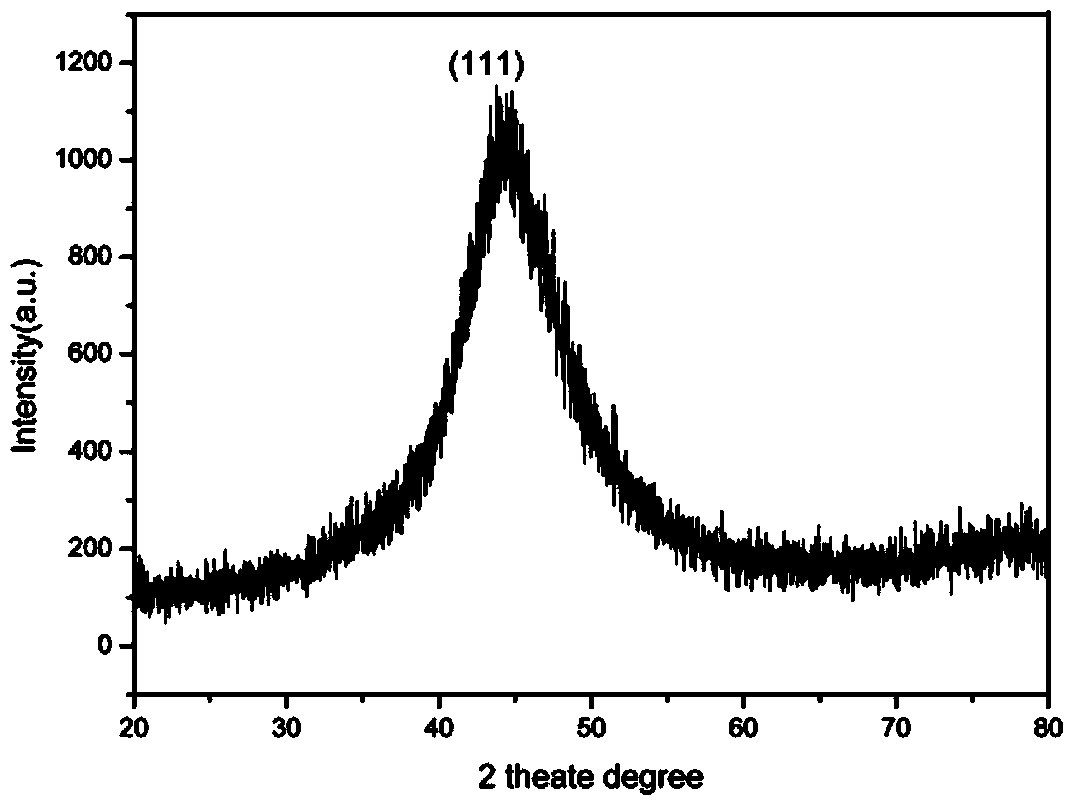

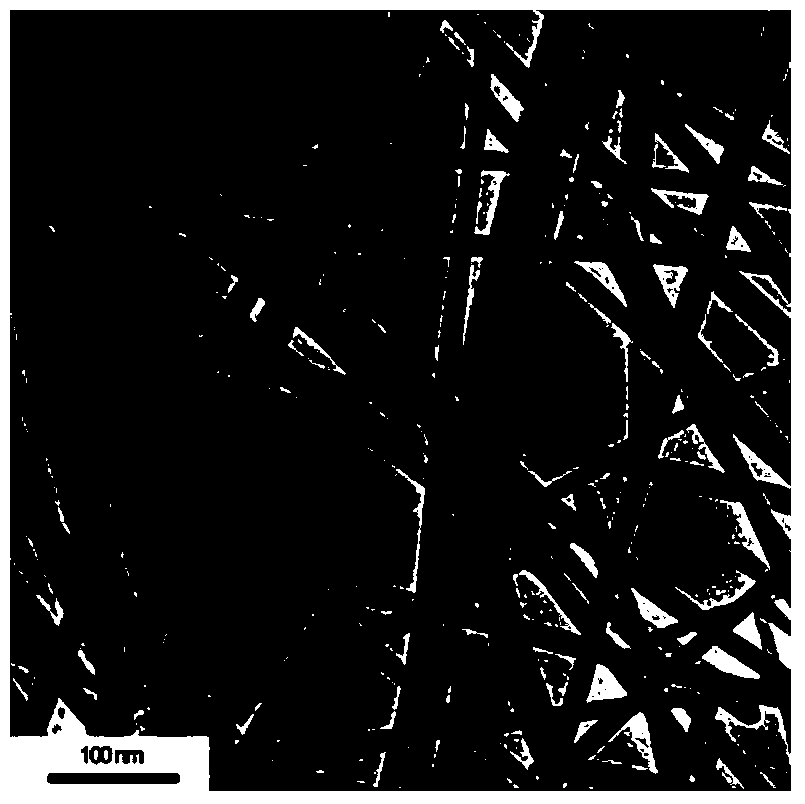

[0042] Example 1 Preparation of nickel-phosphorus alloy nano-perforated spheres

[0043]Prepare nickel sulfate, sodium hypophosphite and sodium hydroxide into 2mol / L, 2mol / L and 2mol / L solutions respectively, take 7.5ml of nickel sulfate (2mol / L) in a 250ml beaker, and then add 45ml of deionized Water, heat the diluted nickel sulfate in a constant temperature water bath at 90±1°C for 8 minutes to make the temperature of nickel sulfate about 80°C, then slowly pour 7.5ml of sodium hydroxide (2mol / L) into the diluted nickel sulfate In the nickel sulfate solution, stir while pouring, and finally obtain a uniform nickel hydroxide colloid. Put the nickel hydroxide colloid in a 100ml reaction kettle, seal it, heat it up to 110°C in an oil bath at 120°C and keep it warm for 24 hours, cool it naturally, take it out and wash it with deionized water for 6 times, and get a concentration of 0.018mol / L Ni(SO 4 ) 0.3 (OH) 1.4 Nanowire suspension (which contains Ni(SO 4 ) 0.3 (OH) 1.4 ...

Embodiment 2

[0044] Example 2 Preparation of nickel-boron alloy nano-perforated spheres

[0045] Prepare nickel sulfate, sodium borohydride and ammonia water into 2mol / L, 2mol / L and 2mol / L solutions respectively, take 9ml of nickel sulfate (2mol / L) in a 250ml beaker, add 45ml of deionized water, and dilute Heat the finished nickel sulfate in a constant temperature water bath at 85±1°C to 70°C for 8 minutes, then slowly pour 9ml of ammonia water into the diluted nickel sulfate solution, stir while pouring, and finally obtain a uniform nickel hydroxide colloid . Put the nickel hydroxide colloid in a 100ml reaction kettle, seal it, keep it warm in an oil bath at 120°C for 24 hours, cool it naturally, take it out and wash it with deionized water for 6 times, and get nickel hydroxide with a concentration of 0.018mol / L Nanowire suspension (which contains 1.37 grams of nickel hydroxide nanowires). Get 10ml of the above-mentioned nickel hydroxide nanowire suspension, add 1 drop of palladium chlo...

Embodiment 3

[0046] Example 3 Preparation of Nickel-Cobalt-Phosphorus Alloy Nano-Perforated Balls

[0047] Prepare nickel sulfate, cobalt sulfate, sodium hypophosphite and sodium hydroxide into 2mol / L, 2mol / L, 2mol / L and 2mol / L solutions respectively, take 5ml nickel sulfate (2mol / L) and 2.5ml cobalt sulfate (2mol / L) in a 250ml beaker, then add 45ml of deionized water, heat the diluted nickel-cobalt sulfate in a constant temperature water bath at 90±1°C for 8 minutes, and then add 7.5ml of sodium hydroxide (2mol / L L) Slowly pour into the diluted nickel-cobalt sulfate solution, stir while pouring, and finally obtain a uniform nickel-cobalt hydroxide colloid. Put the nickel cobalt hydroxide colloid in a 100ml reaction kettle, seal it, keep it warm in an oil bath at 180°C for 12 hours, cool it down naturally, take it out and wash it with deionized water for 6 times, and get a hydroxide with a concentration of 0.018mol / L. Nickel-cobalt nanowire suspension (containing 1.17 grams of nickel-coba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com