Composite circular biochemical film reclaimed water integral treatment equipment and process

A technology of compound circulation and treatment equipment, applied in aerobic and anaerobic process treatment and other directions, can solve the problems of complex equipment structure, poor treatment effect and high operation cost, and achieve the effect of good treatment effect, simple structure and low operation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

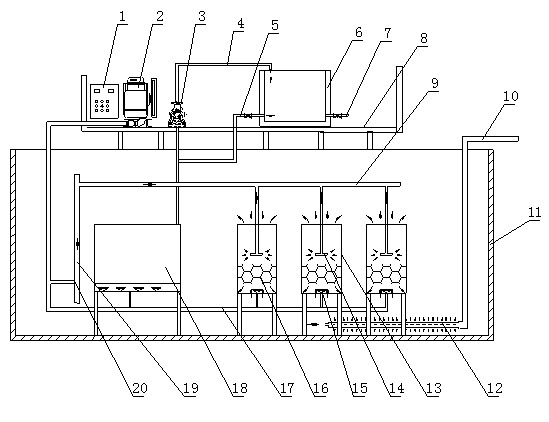

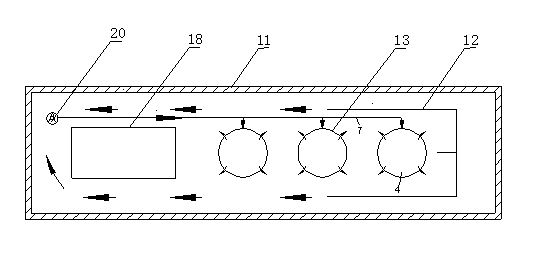

[0019] As shown in the figure, the composite cycle biochemical membrane reclaimed water integrated treatment equipment includes a biochemical area, a membrane separation area, a reclaimed water area, and an equipment area. The biochemical area and the membrane separation area are set in the same biochemical reactor 11, and the biochemical area is set. On the front side of the biochemical reactor 11, the membrane separation zone is located at the rear side of the biochemical reactor 11; as can be seen from the figure, the biochemical reactor 11 is a long treatment box, and the membrane separation zone and the biochemical zone are connected in the box . The sewage inlet 10 is located at the upper part of the biochemical zone of the biochemical reactor, and the upper and lower open aerobic isolation cylinders 13 are arranged in the biochemical zone through supports, and the aerobic isolation cylinder 13 divides the biochemical zone into an anaerobic zone and an aerobic zone, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com