Method for continuously polymerizing chain extension modified polyester

A technology of modified polyester and chain extender, applied in the field of preparing modified polyester by chain extension method, can solve the problems of high cost, poor product quality stability, low production efficiency, etc., and achieve stable quality, excellent thermal stability, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

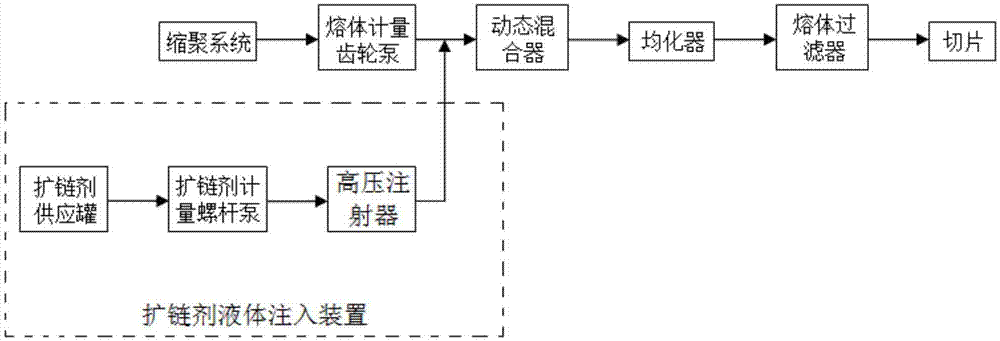

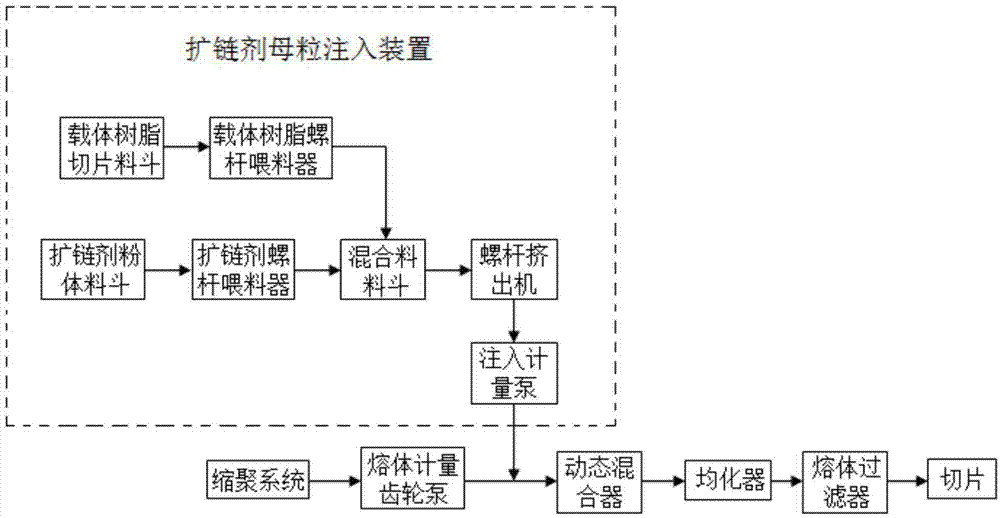

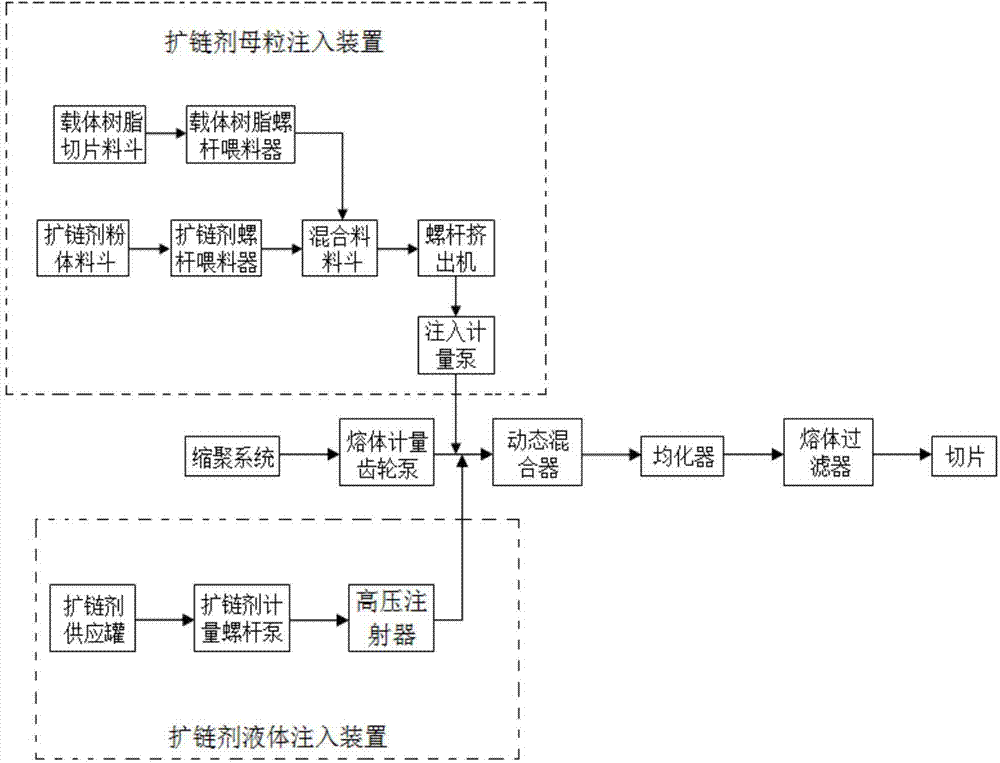

Method used

Image

Examples

Embodiment 1

[0059] (1) The polyethylene terephthalate melt with an intrinsic viscosity of 0.67dl / g is directly transported from the polycondensation system to the melt pipeline by the melt metering gear pump, and the temperature of the melt pipeline is 285°C;

[0060] (2) The hexamethylene diisocyanate in the chain extender supply tank is accurately metered by the chain extender metering screw pump, and then injected into the melt pipeline by a high-pressure syringe, and the injection flow is measured according to the melt metering gear pump. Polyethylene terephthalate The flow ratio control of the alcohol ester melt, the injection amount is 0.01wt% of the melt mass;

[0061] (3) The chain extender injected into the melt pipeline enters the dynamic mixer together with the polyethylene terephthalate melt, and the temperature of the dynamic mixer is 285°C;

[0062] (4) After being uniformly mixed by a dynamic mixer, enter the homogenizer to carry out chain extension homogenization reaction ...

Embodiment 2

[0065] (1) The polybutylene terephthalate melt with an intrinsic viscosity of 0.80dl / g is directly transported from the polycondensation system to the melt pipeline by the melt metering gear pump, and the temperature of the melt pipeline is 250°C;

[0066] (2) The toluene diisocyanate in the chain extender supply tank is accurately metered by the chain extender metering screw pump, and then injected into the melt pipeline by a high-pressure injector, and the injection flow is measured according to the melt metering gear pump for polybutylene terephthalate melt. The flow ratio of the melt is controlled, and the injection amount is 0.05wt% of the melt mass;

[0067] (3) The chain extender injected into the melt pipeline enters the dynamic mixer together with the butylene terephthalate melt, and the temperature of the dynamic mixer is 250°C;

[0068] (4) After being uniformly mixed by a dynamic mixer, enter the homogenizer to carry out chain extension homogenization reaction in t...

Embodiment 3

[0071] (1) Polytrimethylene terephthalate melt with an intrinsic viscosity of 0.78dl / g is directly transported from the polycondensation system to the melt pipeline by the melt metering gear pump, and the temperature of the melt pipeline is 230°C;

[0072] (2) The diphenylmethane diisocyanate in the chain extender supply tank is accurately metered by the chain extender metering screw pump and then injected into the melt pipeline by a high-pressure syringe, and the injection flow is measured according to the melt metering gear pump for polypropylene terephthalate The flow ratio of the melt is controlled, and the injection amount is 0.6wt% of the mass of the melt;

[0073] (3) The chain extender injected into the melt pipeline enters the dynamic mixer together with the polypropylene terephthalate melt, and the temperature of the dynamic mixer is 230°C;

[0074] (4) After being uniformly mixed by a dynamic mixer, it enters a homogenizer to carry out chain extension homogenization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com