Low-smoke halogen-free flame retardant oil-resistance super-soft elastomer cable material and preparation method thereof

An elastomer and cable material technology, applied in the field of halogen-free flame retardant cable material and its preparation, can solve the problems of electrical properties that are difficult to meet national standards, oil resistance needs to be improved, cable aging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of the cable can adopt conventional techniques in the art.

[0057] Preparation

[0058] The third aspect of the present invention provides a method for preparing the low-smoke, halogen-free, flame-retardant, oil-resistant, extra-flexible elastomer cable compound of the present invention, the preparation method comprising the following steps:

[0059] Mix flame retardant A, flame retardant B, lubricant, and antioxidant according to the stated ratio for 5 to 10 minutes, discharge and place, and extrude and granulate with other components according to the ratio to obtain the low-smoke and halogen-free Flame retardant and oil resistant extra soft elastomer cable compound.

[0060] In a specific embodiment of the present invention, in the preparation method, a twin-screw granulator is used for extrusion granulation, and the temperature of each section of the extruder is 150-160° C., 170-180° C. ℃, 180~190℃, 185~195℃, 190~200℃, 200~210℃, 200~210℃, the ...

Embodiment 1

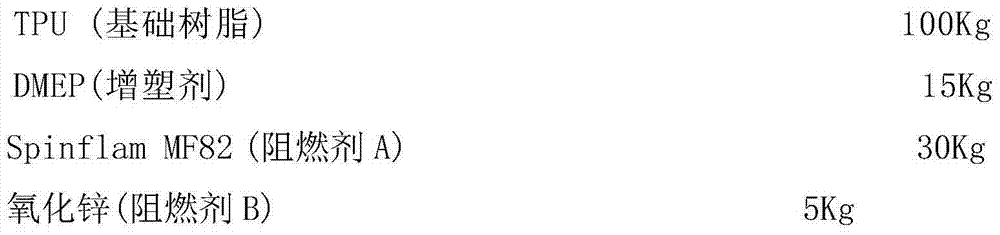

[0069] Each component name and each component parts by weight are as follows:

[0070]

[0071]

[0072] The preparation method of the above-mentioned invention, it comprises the following processing steps:

[0073] Stir and mix Spinflam MF82, zinc oxide, molybdenum trioxide, carbon black, antioxidant 1010, antioxidant 168, and zinc stearate according to the ratio at high speed for 5-10 minutes, put the material out, and extrude it with other components according to the ratio Granulate. The temperature of each section of the extruder starts from the feeding port, which is 150-160°C, 170-180°C, 180-190°C, 185-195°C, 190-200°C, 200-210°C, 200-210°C. The temperature of the head of the machine is 210 ~ 220 ℃.

[0074] The product in Example 1 is subjected to a performance detection test, and each performance value is as shown in the performance example.

Embodiment 2

[0076] Each component name and each component parts by weight are as follows:

[0077]

[0078] The preparation method of above-mentioned cable material is identical with embodiment 1

[0079] The product in Example 2 is subjected to a performance detection test, and each performance value is as shown in the performance example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com