Anti-static emulsion paint

A latex paint, anti-static technology, used in conductive coatings, coatings and other directions, can solve the problem of anti-static agent temperature resistance, water resistance and oil resistance, corrosion resistance and poor durability, affecting the performance of coatings and their coatings, anti- The problem of unstable electrostatic performance, etc., achieves the effect of strong scrub resistance, small specific gravity and good anti-static effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

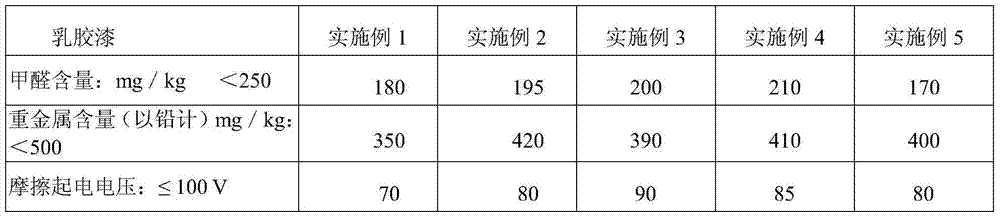

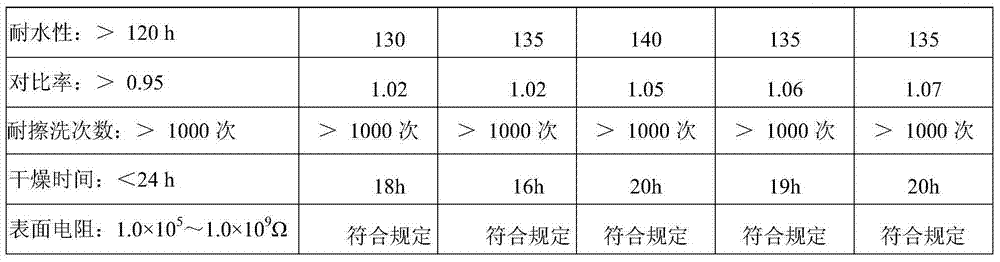

Examples

Embodiment 1

[0033] The vinegar acrylic emulsion of 45 parts by weight and the latex paint auxiliary agent of 0.5 parts by weight are joined in the high-speed disperser, low-speed stirring (400r / min) 10 minutes, then add the conductive titanium dioxide of the filler of 5 parts by weight and 20 parts by weight, Stir at low speed (400r / min) for 20 minutes; then add 29.5 parts by weight of zinc oxide, and stir at low speed (400r / min) for 20 minutes to ensure uniform stirring;

[0034] Wherein, the filler adopts any one or more of superfine kaolin, superfine talcum powder, calcium carbonate and mica powder.

[0035] Among them, the latex paint additives are composed of the following components by weight: 0.05 parts of film-forming aids, 0.025 parts of wetting agents, 0.15 parts of dispersants, 0.07 parts of leveling agents, 0.075 parts of defoamers, and 0.075 parts of thickeners. parts and 0.03 parts of pigments.

Embodiment 2

[0037] The vinegar acrylic emulsion of 40 parts by weight and the latex paint auxiliary agent of 0.3 parts by weight are added in the high-speed disperser, stirred at a low speed (400r / min) for 10 minutes, then the filler of 3 parts by weight and the conductive titanium dioxide of 15 parts by weight were added, Stir at low speed (400r / min) for 20 minutes; then add 25 parts by weight of zinc oxide, and stir at low speed (400r / min) for 20 minutes to ensure uniform stirring;

[0038] Wherein, the filler adopts any one or more of superfine kaolin, superfine talcum powder, calcium carbonate and mica powder.

[0039] Among them, the latex paint additive consists of the following components by weight: 0.045 parts of film-forming aids, 0.015 parts of wetting agents, 0.09 parts of dispersants, 0.06 parts of leveling agents, 0.045 parts of defoamers and 0.045 parts of thickeners. share.

Embodiment 3

[0041] The vinegar acrylic emulsion of 50 parts by weight and the latex paint auxiliary agent of 1.2 parts by weight are joined in the high-speed disperser, low-speed stirring (400r / min) 10 minutes, then add the conductive titanium dioxide of the filler of 7 parts by weight and 25 parts by weight, Stir at low speed (400r / min) for 20 minutes; then add 35 parts by weight of zinc oxide, and stir at low speed (400r / min) for 20 minutes to ensure uniform stirring;

[0042] Wherein, the filler adopts any one or more of superfine kaolin, superfine talcum powder, calcium carbonate and mica powder.

[0043]Among them, the latex paint additives are composed of the following components by weight: 0.15 parts of film-forming aids, 0.06 parts of wetting agents, 0.36 parts of dispersants, 0.20 parts of leveling agents, 0.18 parts of defoamers, and 0.15 parts of thickeners. part and 0.1 part of antifungal agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com