Algae harvesting method taking modified chitosan as flocculant

A harvesting method and flocculant technology, applied in the field of algae harvesting, can solve the problems of difficulty in collecting microalgae, high energy consumption, low income, etc., and achieve the effect of simple preparation process, moderate cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 3 g of chitosan with an average molecular weight of 70 kDa and a degree of deacetylation of 81% to 30 mL of 0.3 mol / L hydrochloric acid solution to completely dissolve the chitosan to obtain a chitosan hydrochloric acid solution.

[0031] Add aminonitrile to the chitosan hydrochloric acid solution, and stir at 90°C for 12 hours to obtain a clear solution, wherein the molar ratio of aminonitrile to chitosan in the chitosan hydrochloric acid solution is 2:1.

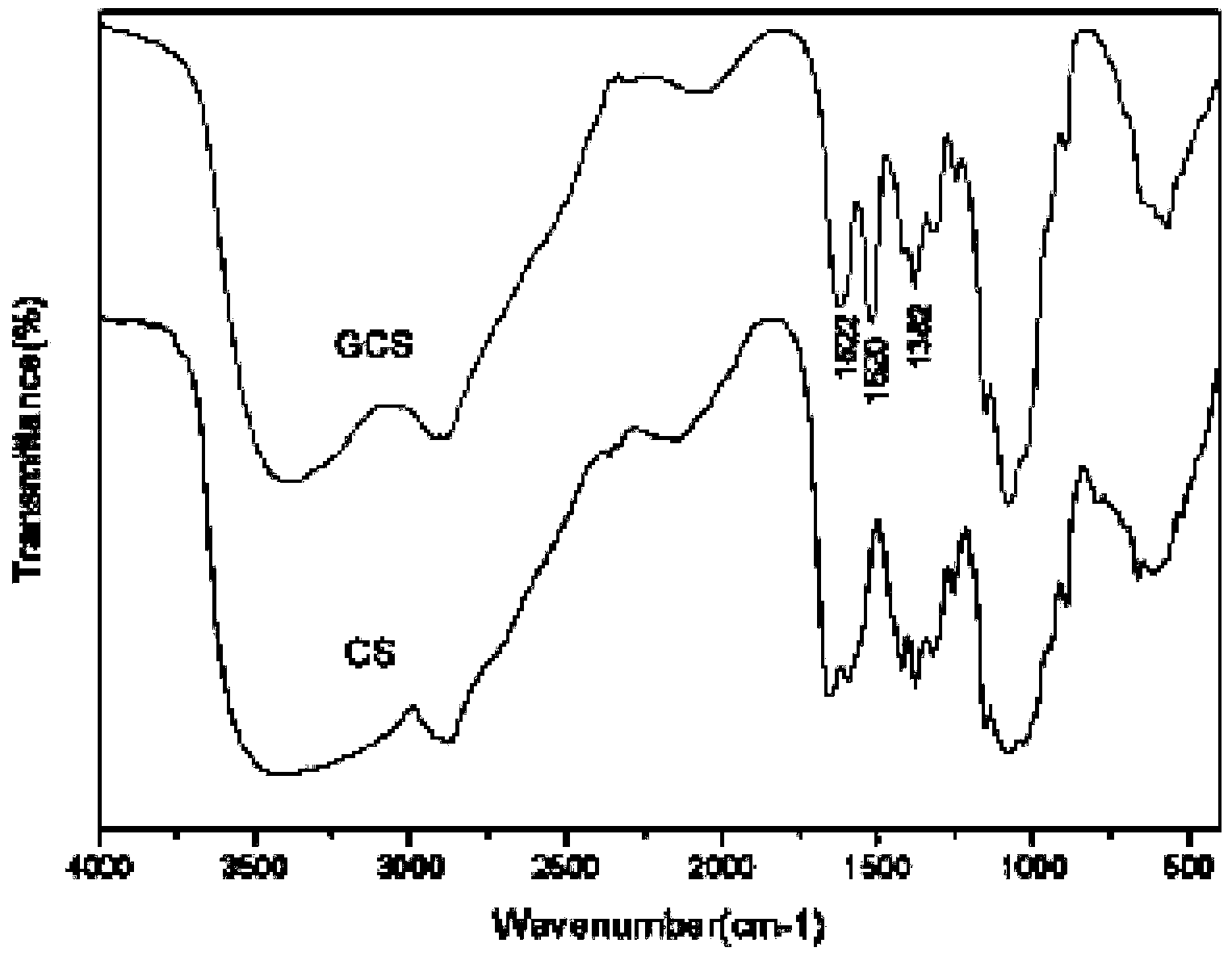

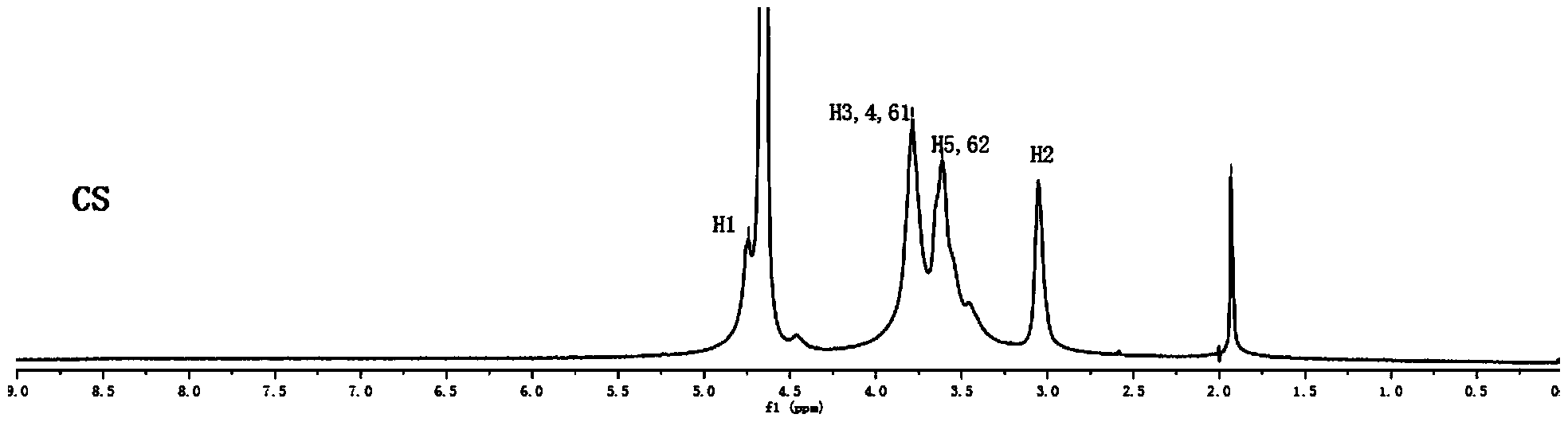

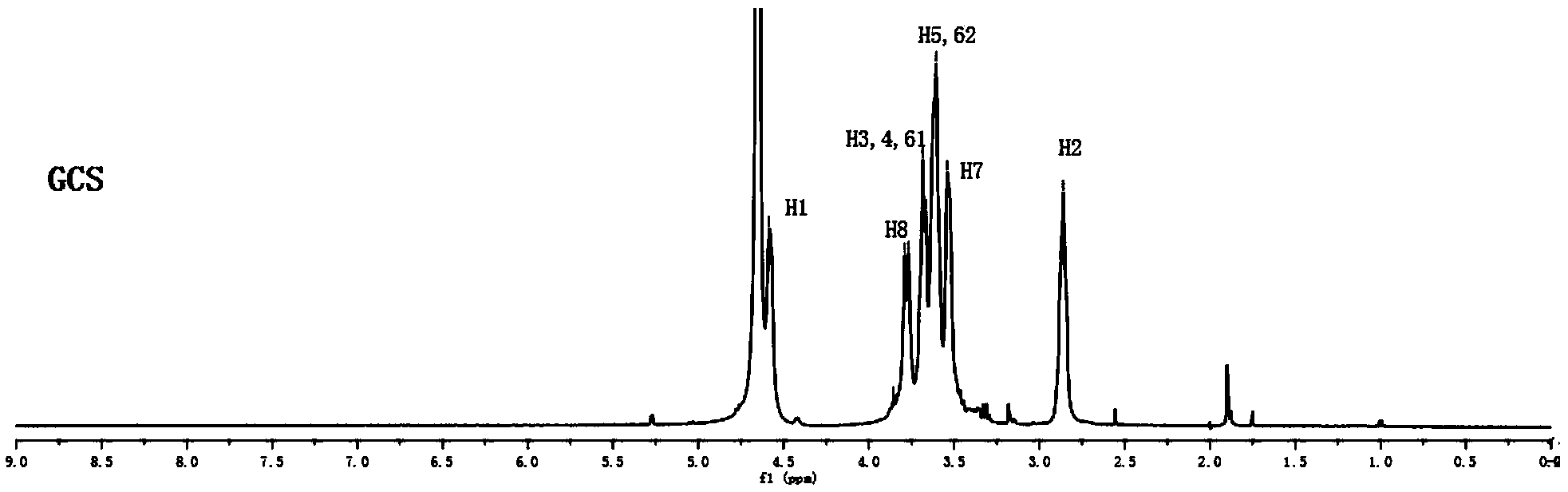

[0032] Put the obtained clear solution into a dialysis bag (MWCO3500), dialyze for 5 days, pre-freeze in a low-temperature refrigerator at -20°C, and then dry it in a freeze dryer to obtain a guanidino-chitosan flocculant. The obtained guanidine-chitosan Sugar flocculant (GCS) and former chitosan (CS) Fourier transform infrared spectrum and NMR test results are shown in figure 1 , figure 2 , image 3 .

[0033] figure 1 Middle 1622cm -1 The absorption peak at corresponds to the guanidine group, indicating ...

Embodiment 2

[0036] Add 3 g of chitosan with an average molecular weight of 70 kDa and a degree of deacetylation of 85% to 30 mL of 0.1 mol / L hydrochloric acid solution to completely dissolve the chitosan to obtain a chitosan hydrochloric acid solution.

[0037] Add aminonitrile to the chitosan hydrochloric acid solution, stir at 95°C for 8h to obtain a clear solution, wherein the molar ratio of aminonitrile to chitosan in the chitosan hydrochloric acid solution is 2:1.

[0038] The obtained clear solution was put into a dialysis bag (MWCO2000), dialyzed for 2 days, pre-frozen in a -20°C low-temperature refrigerator, and then dried in a freeze dryer to obtain a guanidino-chitosan flocculant.

[0039] Cultivate Chlorella in the culture medium for 4 days, take 2 mg of the guanidino-chitosan flocculant prepared above and add it to 1L of the microalgae culture medium, so that the concentration of the flocculant is 2 mg / L, stir with a stirrer for 10 min, and culture the microalgae The solution wa...

Embodiment 3

[0041] Add 2 g of chitosan with an average molecular weight of 70 kDa and a degree of deacetylation of 70% to 30 mL of 0.2 mol / L hydrochloric acid solution to completely dissolve the chitosan to obtain a chitosan hydrochloric acid solution.

[0042] Add aminonitrile to the chitosan hydrochloric acid solution, stir at 85°C for 10 hours to obtain a clear solution, wherein the molar ratio of aminonitrile to chitosan in the chitosan hydrochloric acid solution is 3:1.

[0043] The obtained clear solution was put into a dialysis bag (MWCO3500), dialyzed for 5 days, pre-frozen in a -20°C low-temperature refrigerator, and then dried in a freeze dryer to obtain a guanidino-chitosan flocculant.

[0044] Cultivate Chlorella in the culture medium for 3 days, take 50mg of the guanidino-chitosan flocculant prepared above and add it to 1L of the microalgae culture medium to make the concentration of the flocculant 50mg / L, stir with a stirrer for 8min, and culture the microalgae The solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com