Method for promoting anaerobic fermentation acid production of excess sludge through surfactin

A technology of surfactin and excess sludge, applied in fermentation, biological sludge treatment, etc., can solve the problems of insufficient improvement of anaerobic acid production effect and poor biodegradability, and achieve good promotion effect and easy biodegradation , good surface activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Let the remaining sludge settle at 4°C for 12-24 hours until the concentration of the concentrated sludge in the lower layer is between 10-20g / L, remove the supernatant, and take 300mL of concentrated sludge into a 1L anaerobic fermentation tank ;

[0026] With the supernatant obtained in the previous step, surfactin was dissolved and formulated into a concentration of 40g / L;

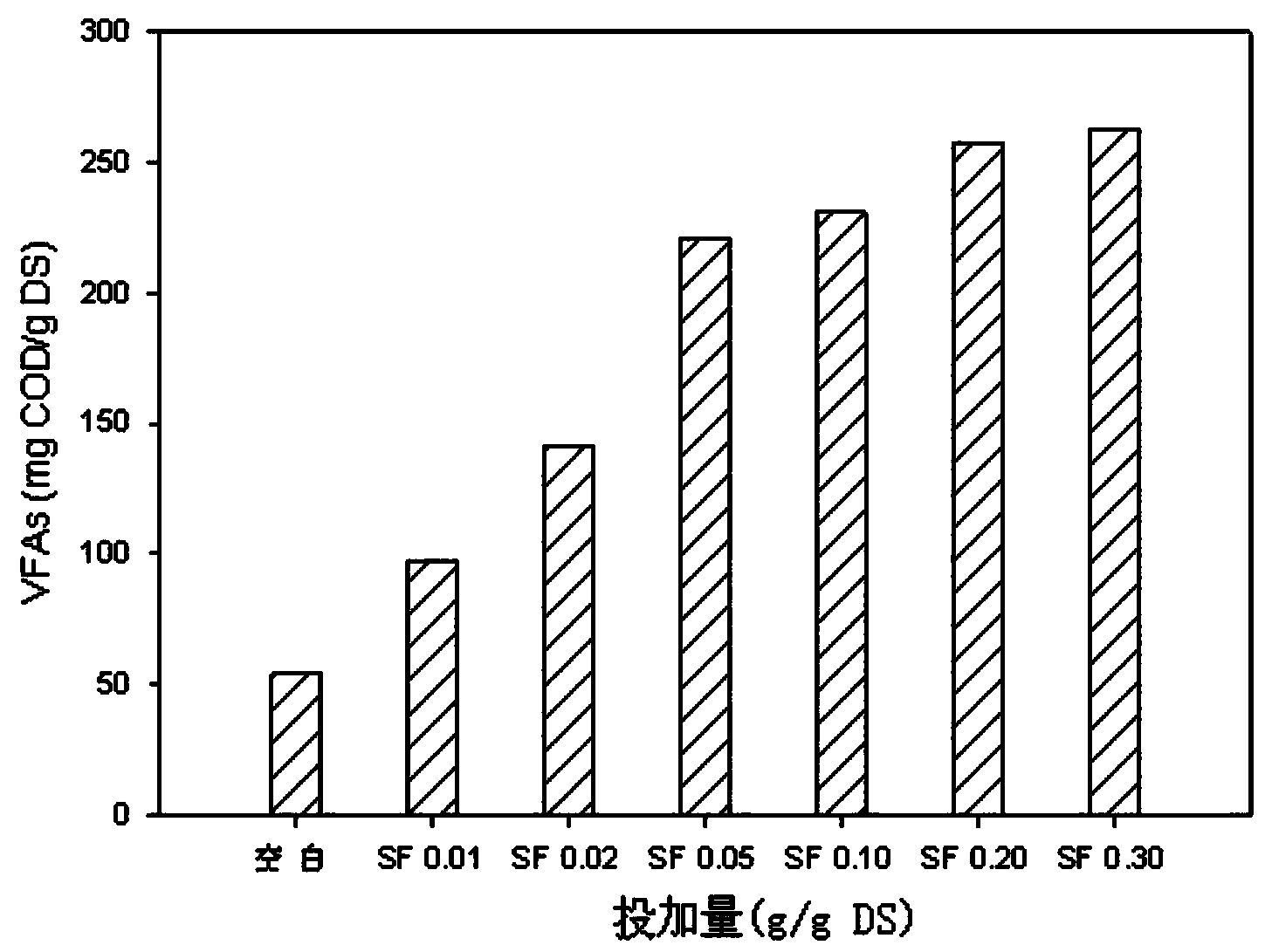

[0027] According to the actual concentration of the concentrated sludge, add surfactin to the fermenter according to the dose of 0.01g (surfactin) / g (dry sludge), and mix quickly and evenly;

[0028] Feed 10 times of the tank volume of nitrogen into the fermenter to remove the oxygen in the tank, then start to carry out anaerobic fermentation to the remaining sludge, and keep the fermenter airtight during the anaerobic fermentation process;

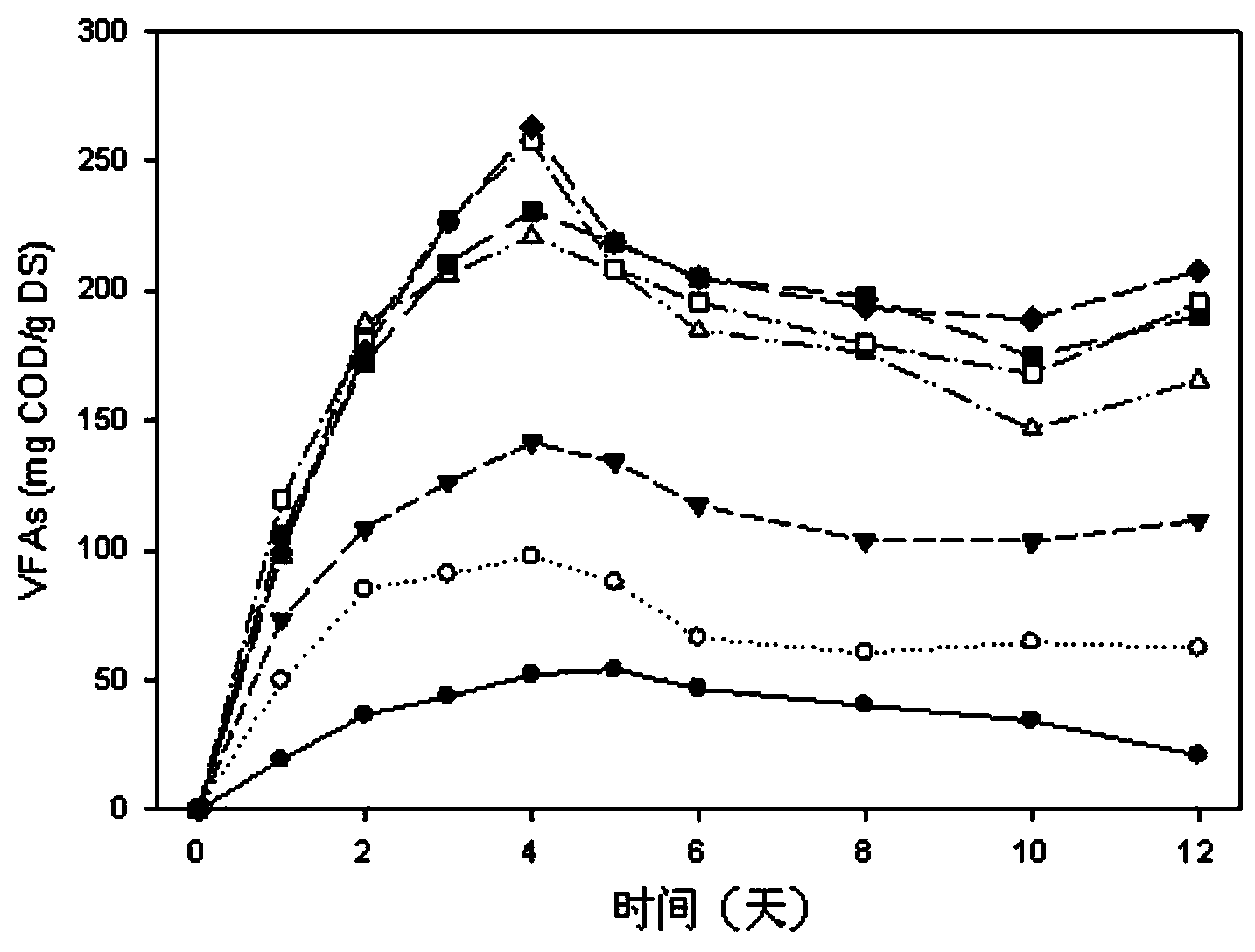

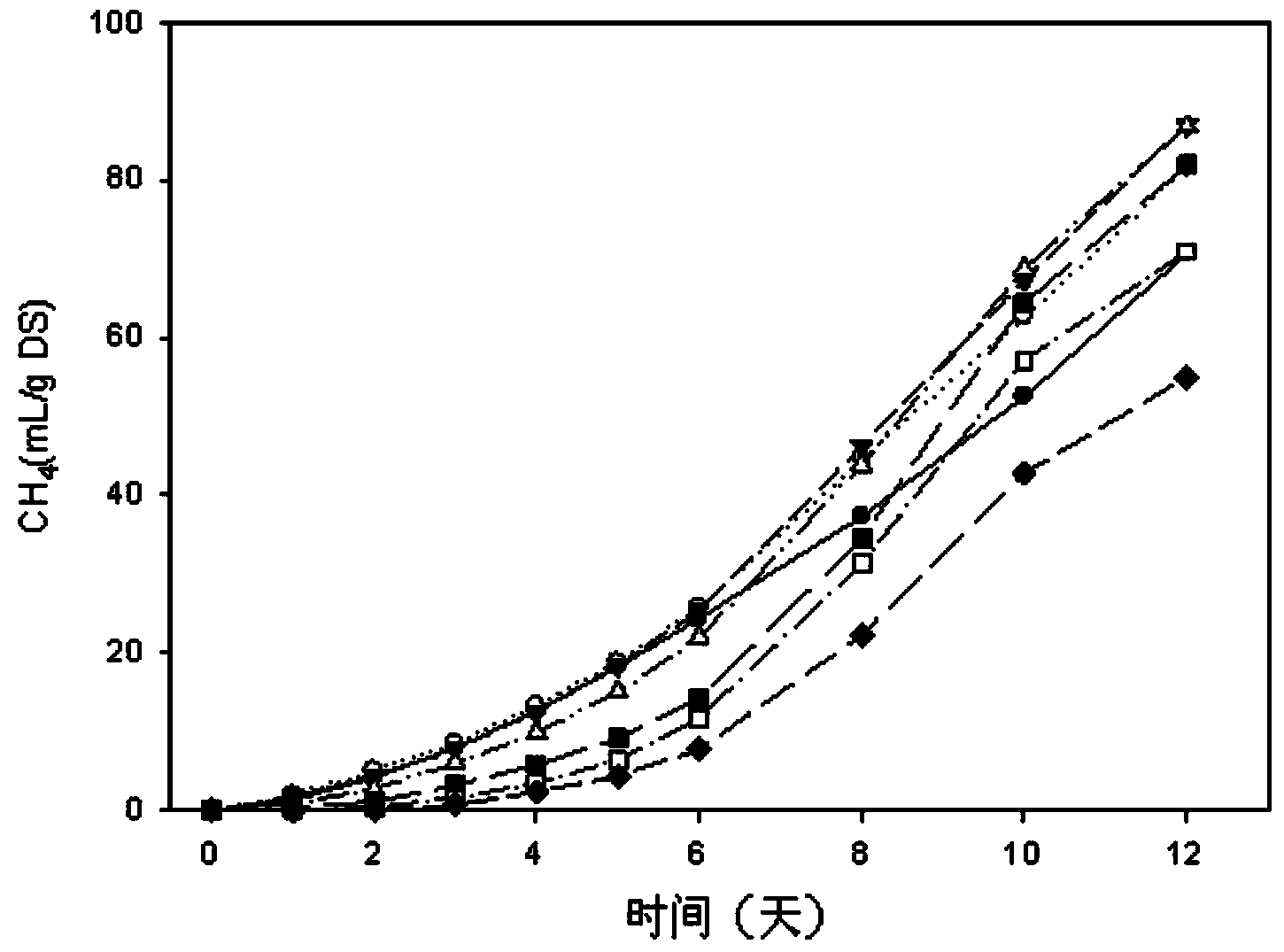

[0029] During the fermentation process, the temperature in the fermenter is maintained between 28-30°C, the mixing speed is between 100-120rpm, and the fer...

Embodiment 2

[0033] Let the remaining sludge settle at 4°C for 12-24 hours until the concentration of the concentrated sludge in the lower layer is between 10-20g / L, remove the supernatant, and take 300mL of concentrated sludge into a 1L anaerobic fermentation tank ;

[0034] With the supernatant obtained in the previous step, surfactin was dissolved and formulated into a concentration of 40g / L;

[0035] According to the actual concentration of the concentrated sludge, add surfactin to the fermenter according to the dose of 0.02g (surfactin) / g (dried sludge), and mix quickly and evenly;

[0036] Feed 10 times of the tank volume of nitrogen into the fermenter to remove the oxygen in the tank, then start to carry out anaerobic fermentation to the remaining sludge, and keep the fermenter tightly closed during the anaerobic fermentation process;

[0037] During the fermentation process, the temperature in the fermenter is maintained between 28-30°C, the mixing speed is between 100-120rpm, and...

Embodiment 3

[0041] Let the remaining sludge settle at 4°C for 12-24 hours until the concentration of the concentrated sludge in the lower layer is between 10-20g / L, remove the supernatant, and take 300mL of concentrated sludge into a 1L anaerobic fermentation tank ;

[0042] With the supernatant obtained in the previous step, surfactin was dissolved and formulated into a concentration of 40g / L;

[0043] According to the actual concentration of the concentrated sludge, add surfactin to the fermenter according to the dose of 0.05g (surfactin) / g (dried sludge), and mix quickly and evenly;

[0044]Feed 10 times of the tank volume of nitrogen into the fermenter to remove the oxygen in the tank, then start to carry out anaerobic fermentation to the remaining sludge, and keep the fermenter airtight during the anaerobic fermentation process;

[0045] During the fermentation process, the temperature in the fermenter was maintained between 28 and 30°C, the mixing and stirring speed was between 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com