Preparation method for graphene-based film and application of graphene-based film to oil-water separation

A graphene membrane and graphene hydrogel technology, applied in semi-permeable membrane separation, separation method, liquid separation and other directions, can solve the problems of lack of comprehensive investigation of oil-water separation performance, complex process flow, and many additives, etc. The effect of light and stable membrane quality, low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

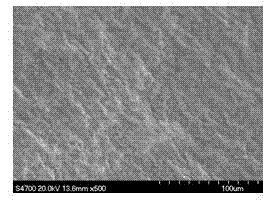

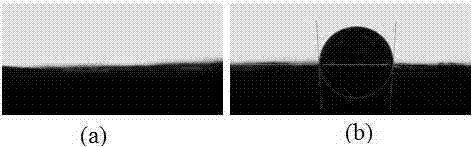

[0028] 100 microliters of ethanedithiol was added to 10 mL of graphene oxide aqueous solution (80 mg / mL), fully stirred and reacted at 70 °C for 4 h to obtain graphene oxide hydrogel. After the hydrogel was dried, graphene oxide xerogel was obtained. ; Under the pressure of 50 kPa, the graphene oxide xerogel was compacted and maintained for 5min, and then the xerogel was immersed in 85% hydrazine hydrate and reacted at 100 °C for 30min to obtain a graphene-based membrane material; finally, the obtained The graphene membrane can be directly used for oil-water separation after Soxhlet extraction in aqueous solution for 5 hours and drying at 60°C.

Embodiment 2

[0030] Add 100 microliters of ethylenediamine to 10 mL of graphene oxide aqueous solution (50 mg / mL), stir well and react at 100 °C for 4 h to obtain graphene oxide hydrogel, and dry the hydrogel to obtain graphene oxide xerogel; Under the pressure of 80 kPa, the graphene oxide xerogel was compacted and maintained for 10 min, and then the xerogel was immersed in 55% hydroiodic acid and reacted at 90 °C for 30 min to obtain a graphene-based membrane; finally, the obtained The graphene membrane can be directly used for oil-water separation after Soxhlet extraction in aqueous solution for 5 hours and drying at 60°C.

Embodiment 3

[0032] 200 microliters of diethylenetriamine was added to 10 mL of graphene oxide aqueous solution (20 mg / mL), fully stirred and reacted at 120 °C for 6 h to obtain graphene oxide hydrogel. After the hydrogel was dried, graphene oxide xerogel was obtained. ; Under the pressure of 80 kPa, the graphene oxide xerogel was compacted and maintained for 5min, and then the xerogel was immersed in 85% hydrazine hydrate solution and reacted at 90°C for 10min to obtain the graphene-based membrane material; finally, the obtained The graphene membrane can be directly used for oil-water separation after Soxhlet extraction in aqueous solution for 5h and drying at 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com