Gasoline-electric and hydraulic compound hybrid power transmission system

A hybrid power and transmission system technology, applied in the field of vehicle power transmission system, can solve the problems of low speed, unsuitable for cars, large buses, hydraulic motor output speed should not be too high, total transmission efficiency drops quickly, etc., to achieve optimal utilization , Improve the overall efficiency and simplify the structure of the transmission system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

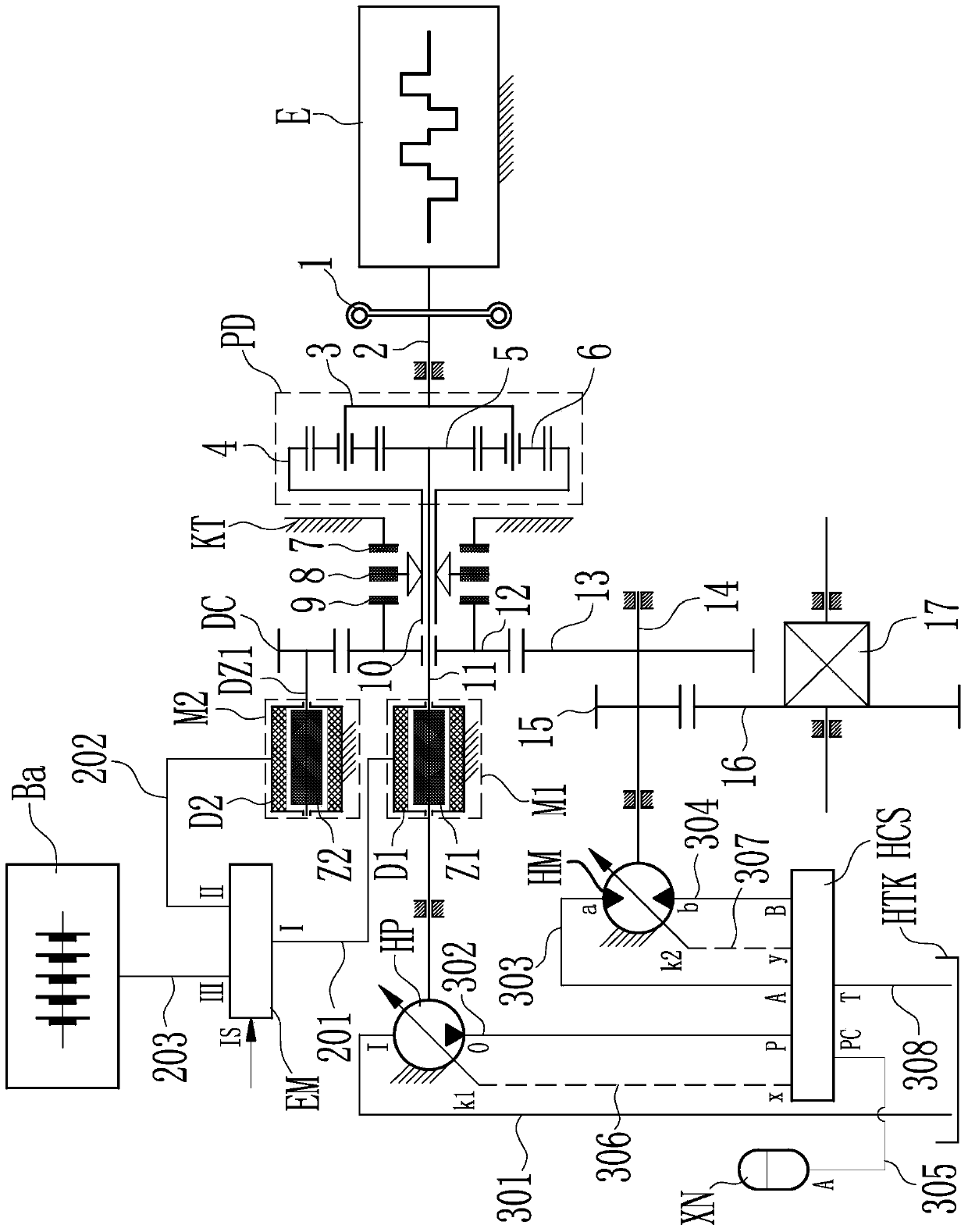

[0043] Embodiment 1: The first technical solution of a hybrid power transmission system with hybrid electric and hydraulic pressure

[0044] See attached figure 1 , attached Figure 4 , attached Figure 5 As shown, the oil-electric and hydraulic hybrid transmission system consists of three parts: engine and mechanical transmission module, electric transmission module and hydraulic transmission module.

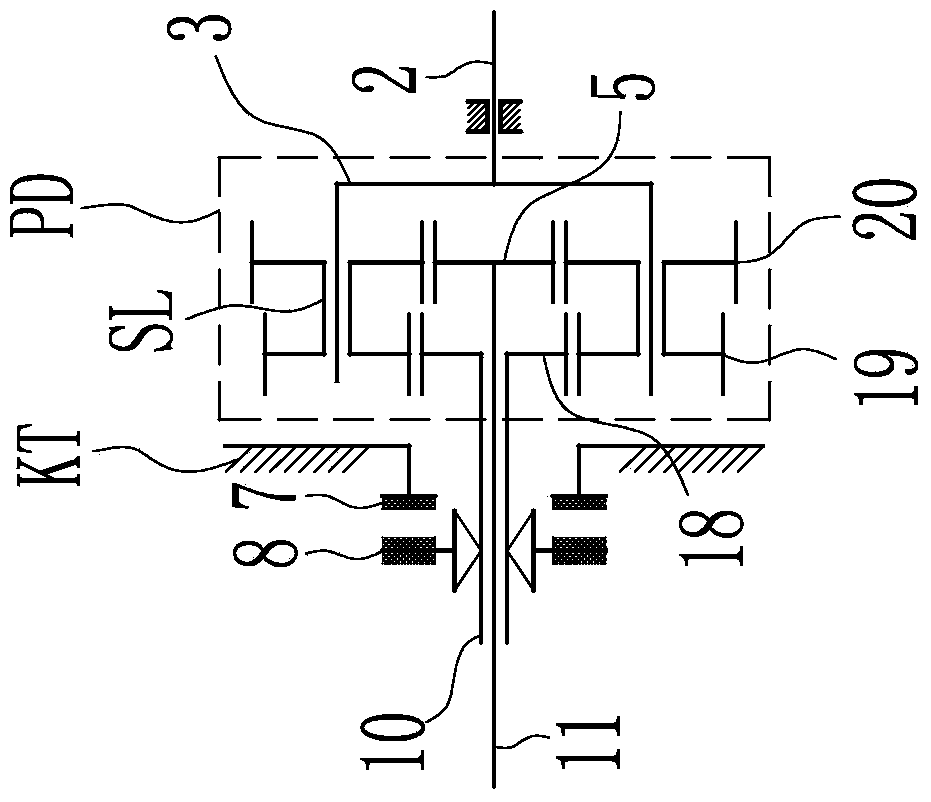

[0045] The engine and mechanical transmission module includes engine E, shock absorber 1, power splitter PD, clutch, gear transmission mechanism, differential 17 and system housing KT, wherein:

[0046] The output end of the crankshaft of the engine E is transmission-connected to the input end of the power distributor PD through the shock absorber 1; Damping spring torsional shock absorber.

[0047]The power distributor PD is a NGW type planetary gear mechanism, the NGW type planetary gear mechanism includes a distributor input shaft 2, a planet carrier 3, an inner ring gea...

Embodiment 2

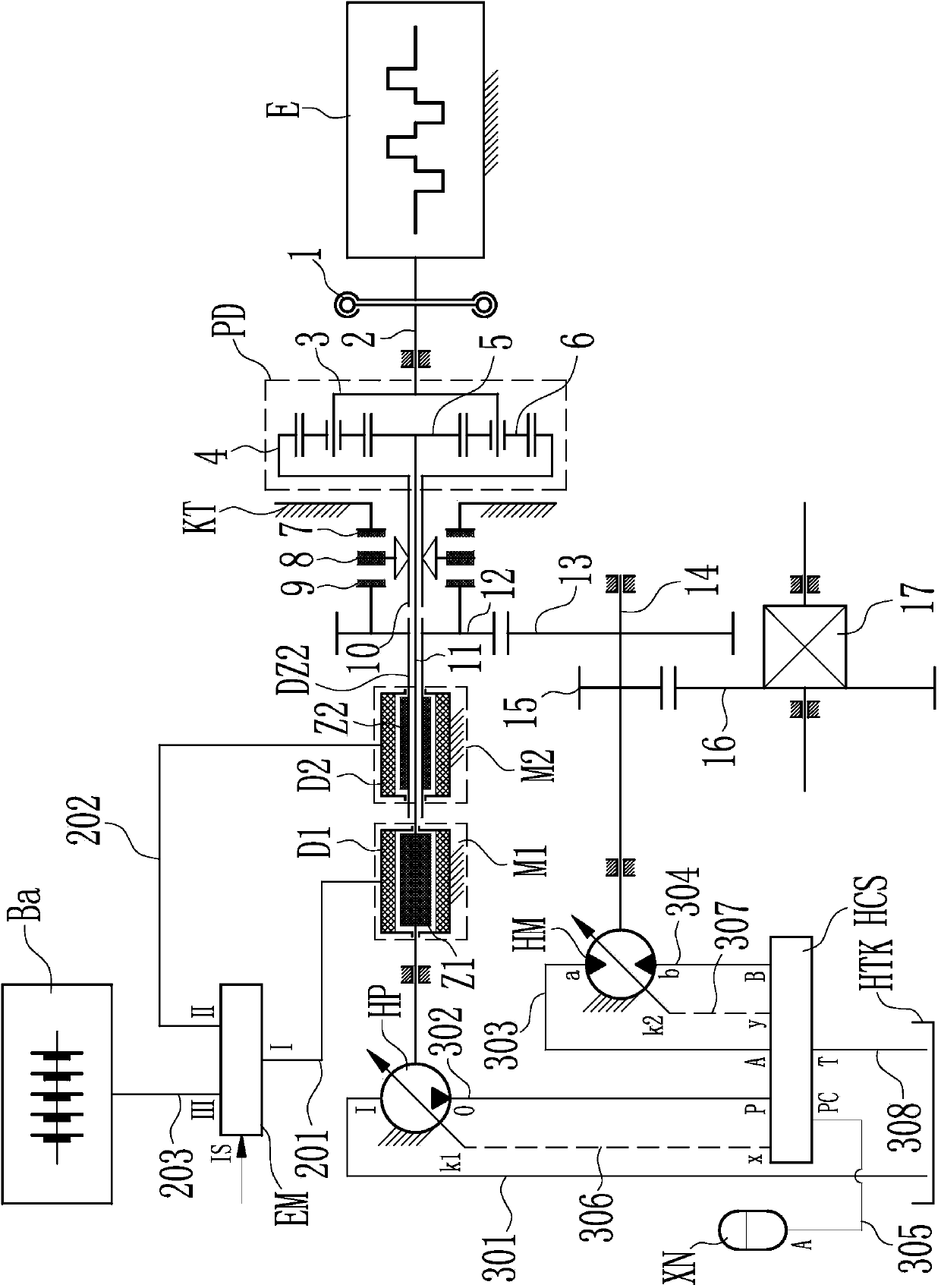

[0123]Embodiment 2: The second technical proposal of a hybrid power transmission system with hybrid electric and hydraulic pressure

[0124] See attached figure 2 , attached Figure 4 , attached Figure 5 As shown, an oil-electric and hydraulic hybrid power transmission system shown in this embodiment is generally the same as the aforementioned embodiment 1, and is composed of three parts: an engine and a mechanical transmission module, an electric transmission module and a hydraulic transmission module. The difference from the previous embodiment 1 is:

[0125] Regarding the transmission connection mode between the second motor rotor Z2 and the distributor output gear 12, please refer to the attached figure 2 In Embodiment 2, a motor sleeve shaft DZ2 is provided for the second motor M2, and the motor sleeve shaft DZ2 is sleeved on the second output shaft 11 and is rotatably supported relative to the second output shaft 11. One end of the motor sleeve shaft DZ2 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com