Reverse-flow type horizontal flow hydrogen substrate bio-membrane reactor based on carbon dioxide as carbon source

A biofilm reactor, carbon dioxide technology, applied in chemical instruments and methods, biological water/sewage treatment, by-product vaporization, etc. Destroy the oxygen-deficient environment of the reactor, and achieve the effect of facilitating off-line cleaning and replacement, facilitating full degradation, and avoiding gas mass transfer problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

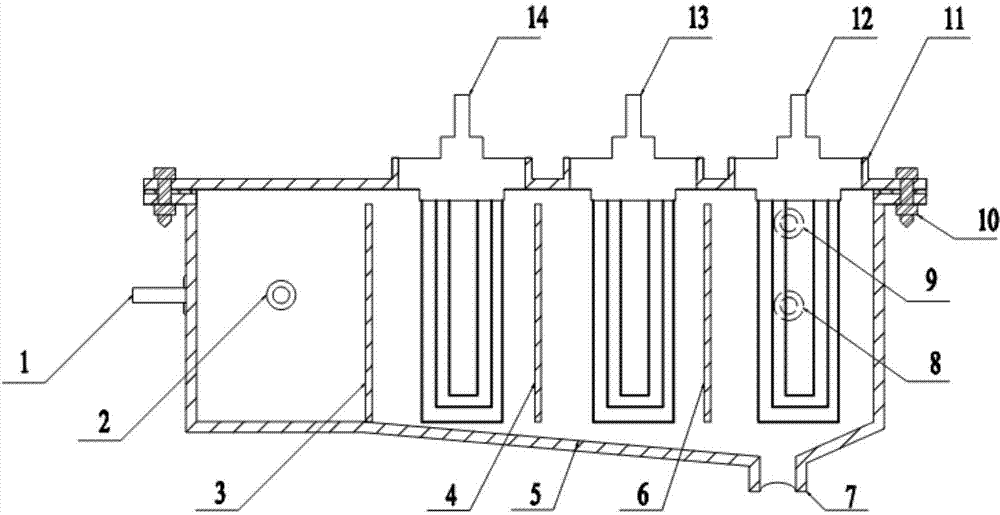

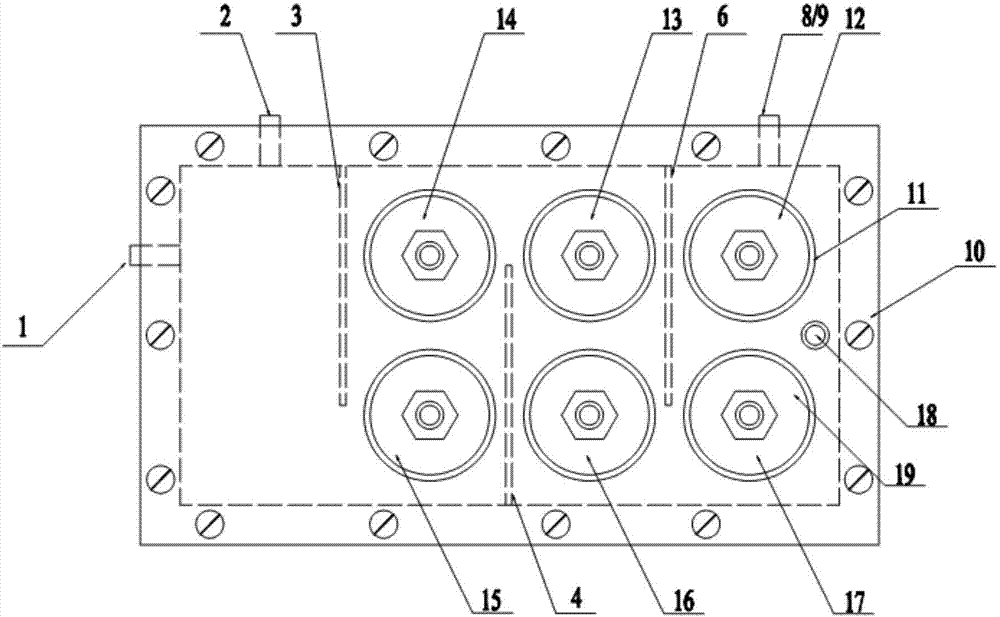

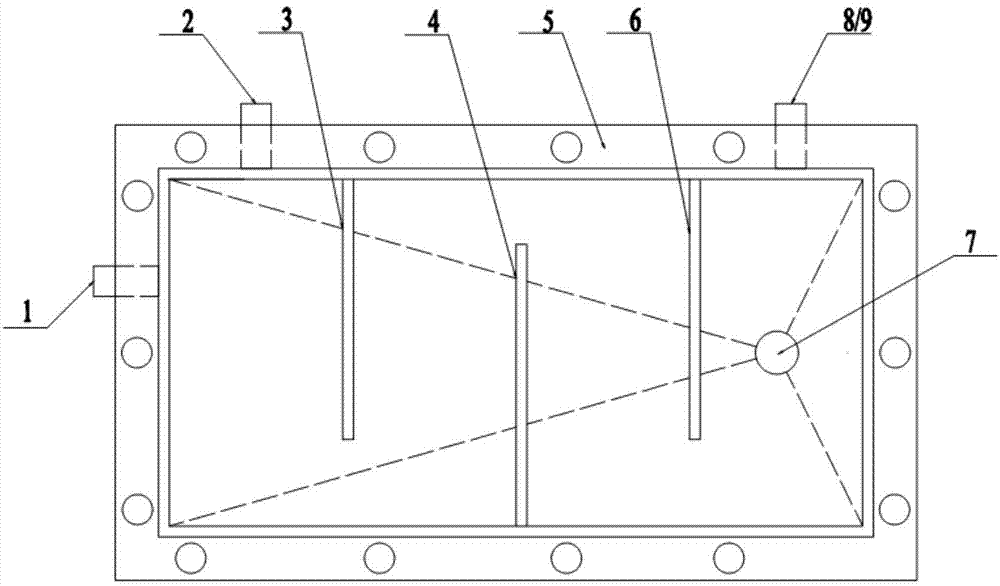

[0031] First, make the reactor box, such as Figure 1-4 , the reactor box 5 is a horizontal cuboid, the shape of the sludge bucket at the bottom is an inclined bucket, and the end of the sludge bucket is equipped with a sludge discharge port 7, which is made of plexiglass material and connected as a whole by welding process . Then punch a hole at the set position of the reactor box 5, and weld the short pipe, respectively, the return water inlet 1 on the left end side wall, the water inlet 2 on the left end rear side wall, and the right end rear side wall from top to bottom The overflow outlet 9 and the backflow outlet 8. Then there are 3 deflectors welded with plexiglass inside the reactor box, which are respectively the first deflector 3, the second deflector 4 and the third deflector 6. The positions of the three deflectors are the same as The positions of the 6 membrane modules are related, and the tops of the 6 membrane modules located in the reactor box 5 are fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com