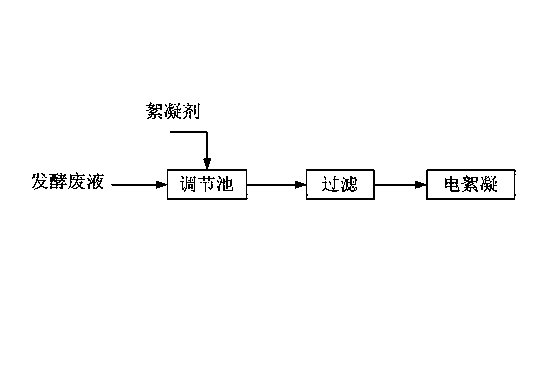

Pretreatment method for cellulosic ethanol waste fermentation broth

A cellulosic ethanol, fermentation waste liquid technology, applied in natural water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. time, the effect of shortening the operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

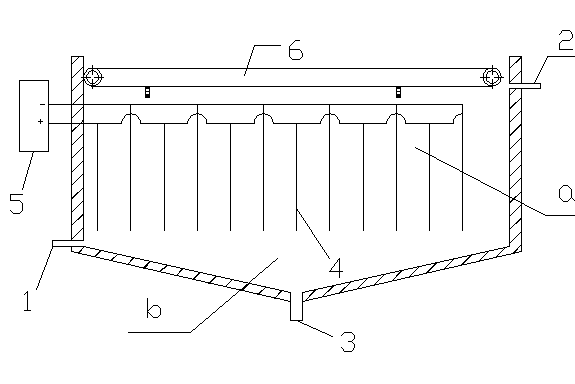

[0028] After adding cationic polyacrylamide (PAM) to the conditioning tank, plate-and-frame pressure filtration is carried out, and the effluent after pressure filtration enters the electro-flocculation device for treatment. There are 6 electrode plates in the electroflocculation reaction area, the distance between the electrode plates is 40mm, and the immersion area is 165cm 2 . The operating conditions and treatment results are shown in Table 1.

[0029] Table 1 Operating conditions and processing results of each processing unit

[0030] processing unit operating conditions Influent water quality process result Flocculation-Press Filtration Treated water volume=10L, PAM=5.0 mg / L, filtration pressure=0.35 MPa COD=180000mg / L, SS=128000mg / L COD=115000mg / L, SS=1360mg / L, the water content is 75wt% solid product 1.63kg, the filtration time is 23 min Electroflocculation The electrode voltage is 20-22V, the current is 4.12-5.69A, and the wastewater...

Embodiment 2

[0033] The processing conditions are the same as those in Example 1, and the operating conditions and processing results are shown in Table 2.

[0034] Table 2 Operating conditions and processing results of each processing unit

[0035] processing unit operating conditions Influent water quality process result Flocculation-Press Filtration Treated water volume=10L, PAM=0.5mg / L, filtration pressure=0.35MPa COD=180000mg / L, SS=128000mg / L COD=119000mg / L, SS=1730mg / L, the water content is 75wt% solid product 1.52kg, the filtration time is 28min Electroflocculation The electrode voltage was 22-25V, the current was 5.15-7.53 A, and the wastewater residence time was 25 min. COD=119000mg / L, SS=1730mg / L COD=87500mg / L, SS=65mg / L

[0036] Using the treatment method of flocculation-press filtration-electro-flocculation, when the dosage of PAM was 0.5 mg / L, the final removal rates of COD and SS were 51.39 wt% and 99.95 wt%, respectively, and the pret...

Embodiment 3

[0043] The filtrate (COD=85000mg / L, SS=46mg / L) after flocculation-press filtration-electro-flocculation pretreatment in Example 1 was diluted 4 times and then subjected to anaerobic biological treatment, and the C:N:P ratio was 200:5 Add N and P nutrients in the ratio of :1. In the batch experiment, 10 g of domesticated anaerobic flocculent sludge was added to the shake flask, and 1 L of filtrate was changed every 24 hours. The COD of the influent and effluent was measured. between. Granular sludge appeared after 20 days of continuous culture.

[0044] The fermentation waste liquid was filtered and diluted 4 times, and then anaerobic biological treatment was carried out according to the method of Example 2, and the removal rate of COD was between 85wt% and 92wt%. Granular sludge appeared after 37 days of continuous culture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com