Method for extracting fish oil from internal organs of elopichthys bambusa by utilizing neutral protease

A neutral protease and fish oil technology, which is applied in the production of fat/fat and fat production, can solve the problems of narrow range of process parameters, high cost, and difficulty in industrial production, and achieve a wide range of process parameters, low cost and difficulty. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0011] The specific embodiment of the present invention comprises the following steps:

[0012] (1) Remove gallbladder, swim bladder and intestinal digesta from the viscera of almond carp, wash, drain and mince into a homogenate;

[0013] (2) Mix the homogenate and water at a weight ratio of 1:1.0~1:3.0, stir evenly, adjust the pH to 6.5~7.0 with hydrochloric acid or sodium hydroxide, and add 2.0%~ 3.0% neutral protease, shake well, raise the temperature to 40-55°C, and carry out the enzymatic hydrolysis reaction for 2.0-3.0 hours.

[0014] (3) Centrifuge the enzymatic solution at 4000-5000r / min for 10-20 minutes, and then divide it into four layers, from top to bottom: fish oil layer, non-enzymatic layer, enzymatic solution layer, and residue Layer, absorb the upper layer to get fish oil.

[0015] Optimally, in step (2), the weight ratio of homogenate to water is 1:1.25, the pH value is 7.0, the amount of neutral protease added is 2.0% of the weight of carp viscera, the enz...

Embodiment 1

[0020] (1) Remove gallbladder, swim bladder and intestinal digesta from the viscera of almond carp, wash, drain and mince into a homogenate;

[0021] (2) Mix the homogenate and water at a weight ratio of 1:1.25, stir evenly, adjust the pH to 7.0 with sodium hydroxide, add 2.0% neutral protease based on the weight of carp viscera, shake well, and heat up to 45 ℃, carry out enzymatic hydrolysis reaction for 2.0h;

[0022] (3) The enzymatic solution was centrifuged at 4500r / min for 15 minutes, and after centrifugation, it was divided into four layers, from top to bottom: fish oil layer, non-enzymatic layer, enzymatic solution layer, and residue layer, Absorb the upper layer to get the fish oil.

[0023] The extraction rate of crude fish oil was 92.13%. The analysis results of its physical and chemical properties are shown in Table 4 Crude Fish Oil Sample 1. It can be seen that the fish oil extracted by this method has reached the secondary standard of crude fish oil.

Embodiment 2

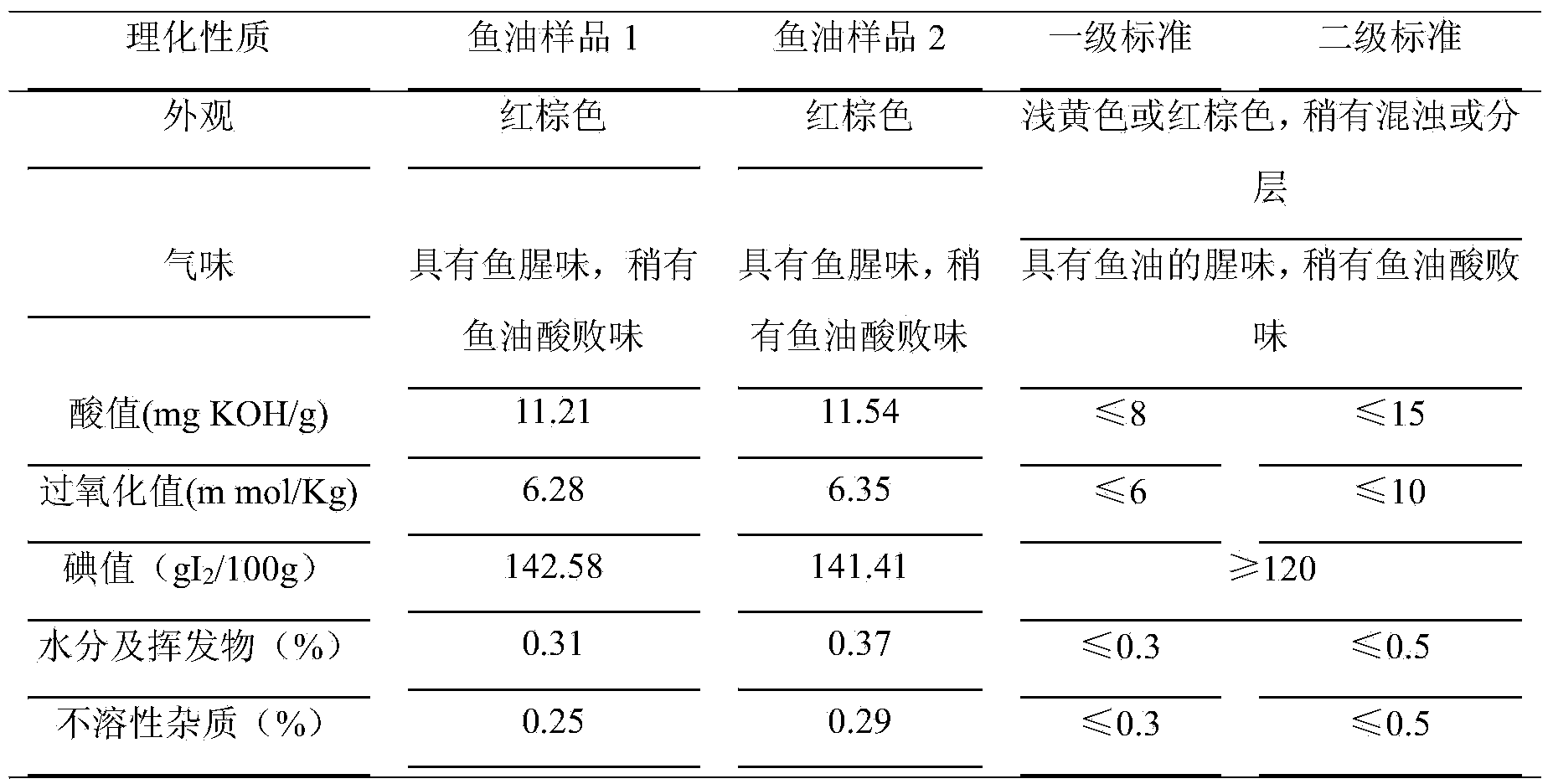

[0025] The operation steps are the same as in Example 1, and the process parameters are: material-to-liquid ratio 1:1.5, pH to 7.0, based on the weight of carp offal, add 2.5% neutral protease, shake well, heat up to 55°C, and carry out enzymatic hydrolysis reaction for 3.0 hours ; The extraction rate was 92.02%. The analysis results of its physical and chemical properties are shown in Table 1, fish oil sample 2. The extracted fish oil has reached the secondary standard of fish oil. The experimental data are shown in Table 1 below:

[0026] Table 1

[0027]

[0028] The grading standard of fish oil in the above table refers to SC / T3502-2000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com