Aluminum-silicon-boron nitride sealed composite powder material, coating and preparation of powder material

A technology of aluminum silicon boron nitride and composite powder, which is applied in metal material coating process, coating, fusion spraying, etc., can solve the problems of easy burning and scattering, low coating, large difference in particle size and specific gravity, etc. Achieve the effects of excellent wearability and thermal stability, good spraying adaptability and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The embodiment of the present invention also provides a method for preparing the above-mentioned aluminum silicon boron nitride sealing composite powder material, including:

[0024] Use aluminum-silicon alloy powder, hexagonal boron nitride powder and binder as raw materials;

[0025] Hexagonal boron nitride powder adopts: agglomerated hexagonal boron nitride powder made by agglomerating, sintering, and crushing hexagonal boron nitride ultrafine powder with a particle size of less than 10 μm;

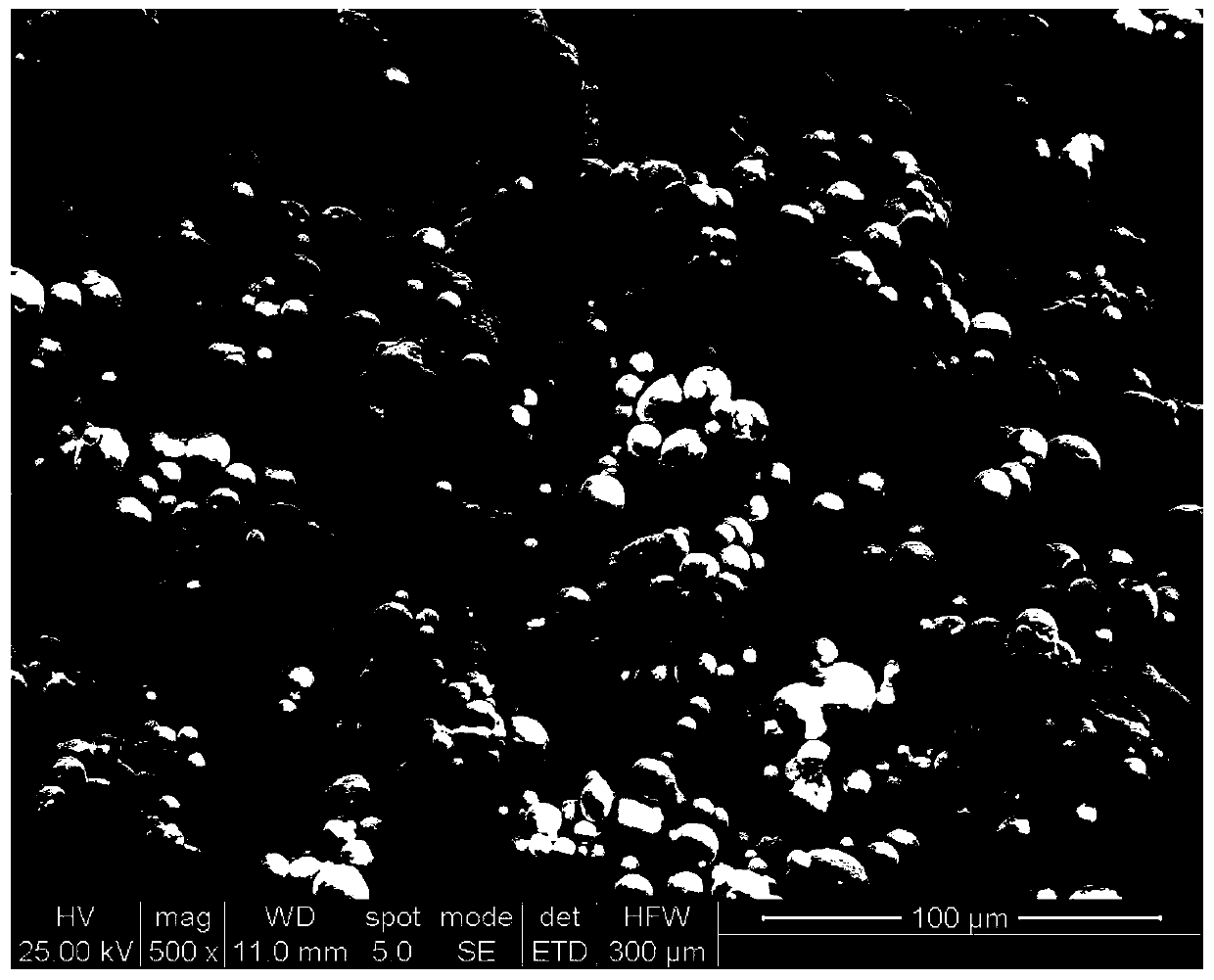

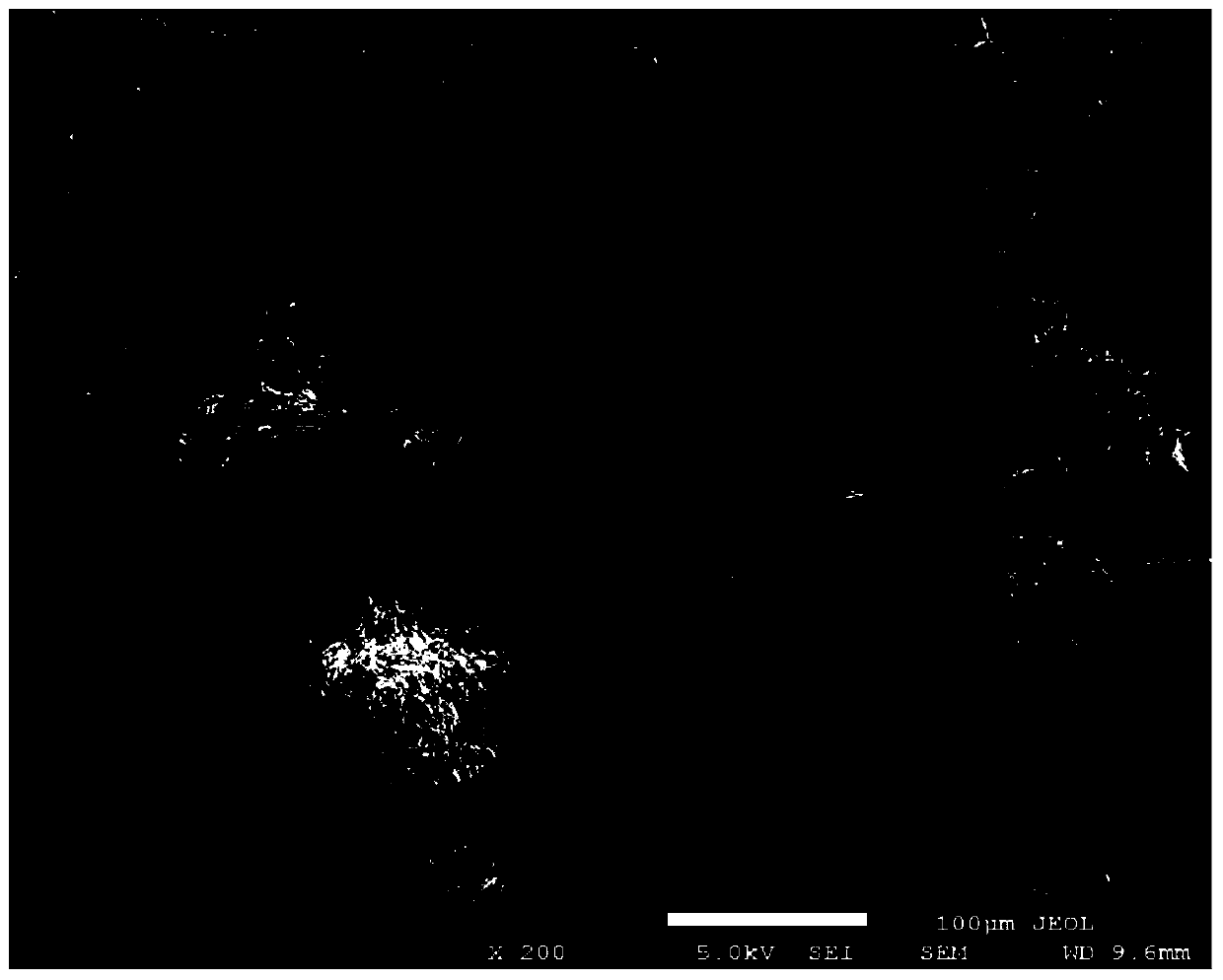

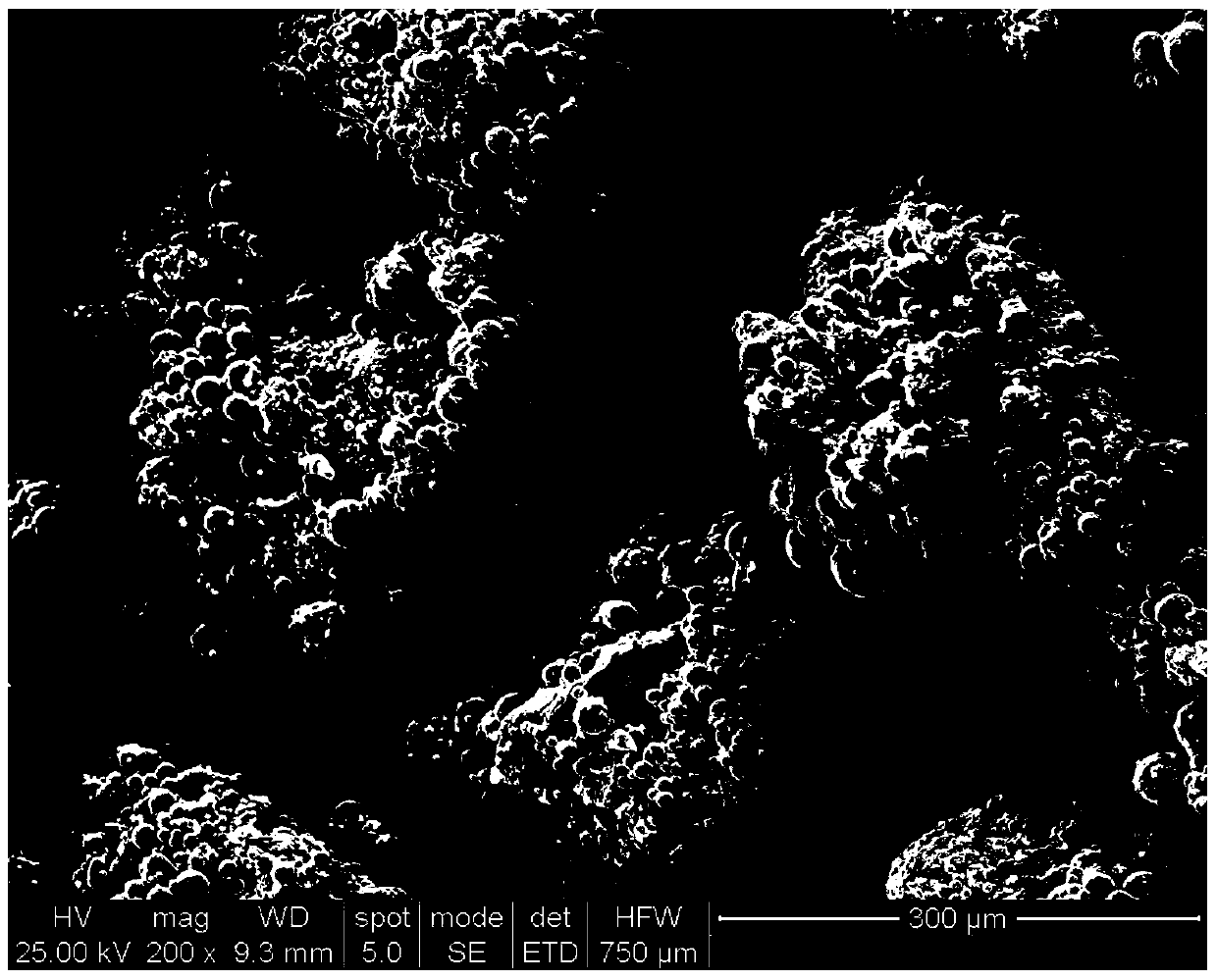

[0026] Composite powder preparation: The aluminum-silicon alloy powder is uniformly reunited and coated on the surface of the hexagonal boron nitride powder through a binder to form a number of reunion-coated particles. The powder material composed of the reunion-coated particles is the aluminum-silicon-boron nitride sealant Composite powder material.

[0027] In the above method, because the hexagonal boron nitride powder is produced by the method of adhesive agglomeration-vac...

Embodiment

[0049] Take raw materials: Al: 87-89wt%, Si: 11-13wt%; put it into vacuum atomization equipment, use intermediate frequency induction heating, after the alloy liquid is homogenized, use argon atomization to obtain aluminum-silicon alloy powder;

[0050] The large-grain hexagonal boron nitride is prepared by the atmosphere-protected solid-phase sintering method, and the raw material used is 5-8 μm hexagonal boron nitride ultrafine powder; solid-phase sintering is a conventional powder metallurgy technology, the purpose is to make the material interparticle at high temperature Solid phase diffusion, here in order to obtain a dense boron nitride sintered body; the sintering process parameters are: temperature 2000-2300 ℃, sintering time 8-12h, sintering under vacuum or nitrogen protective atmosphere; adhesive agglomeration process should be used in advance before sintering The superfine boron nitride powder is agglomerated, and the binder used is alkyd varnish; after sintering, me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com