CCD manufacturing technology based on non-intrinsic impurity adsorbing technology

A manufacturing process and extrinsic technology, which is applied in the field of CCD manufacturing process based on extrinsic gettering technology, can solve the problem of reducing the stress of silicon nitride film, disappearing extrinsic gettering effect, and reducing gettering effect in the strain region and other issues, to achieve the effect of improving gettering ability, reducing dark current, and improving device quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

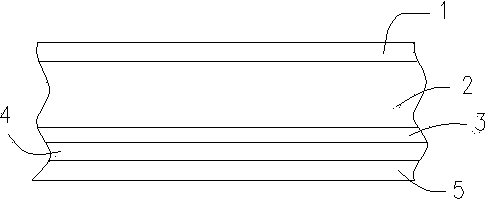

[0026] The silicon substrate is provided as follows:

[0027] A. Deposit a silicon film on the upper surface of the substrate layer 2 by CVD (chemical vapor deposition), and the deposited silicon film forms the epitaxial layer 1. The thickness of the epitaxial layer is usually 8-20 μm, and the doping concentration of boron ions in the epitaxial layer is usually 4E14~2E15cm -3 ;

[0028] B. Treat the lower surface of the substrate layer 2 by means of mechanical damage, laser damage or ion implantation damage to form a damaged layer 3 on the back, and the density of the damage center is 2E14cm -3 above;

[0029] C. Deposit a polysilicon film or a silicon nitride film on the surface of the damaged layer 3 on the back side by CVD, the polysilicon film or silicon nitride film forms the strained layer 4, and the thickness of the strained layer is more than 800nm;

[0030] The gate dielectric is formed, and the gate dielectric is SiO 2 / Si 3 N 4 Composite medium.

[0031] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com