Vinyl chloride high-boiling residue rectification device and vinyl chloride high-boiling residue rectification separation method

A technology for vinyl chloride and high boilers, which is applied in the rectification and separation of high boilers of vinyl chloride and rectification devices for high boilers of vinyl chloride, which can solve the problems of environmental pollution, waste of resources, complex components, etc., and improve the utilization rate of heat energy , reduce pollution, reduce heat loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

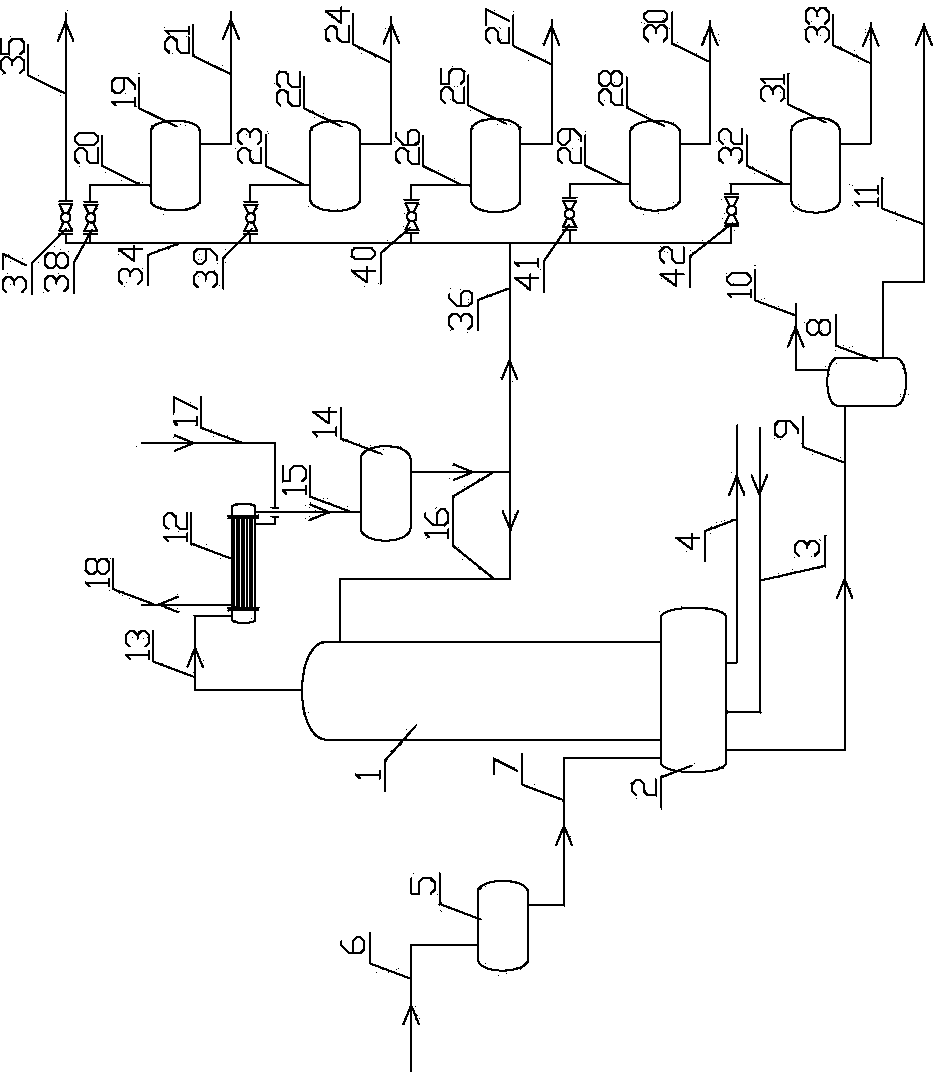

[0013] Implementation 1, as attached figure 1 As shown, the vinyl chloride high boiler rectification device comprises a batch rectification tower 1, a raw material tank 5, a residue storage tank 8, a condenser 12, a reflux tank 14, a dichloroethylene storage tank 19, and a dichloroethane storage tank 22 , trichlorethylene storage tank 25, trichloroethane storage tank 28, transition storage tank 31 and control supervisor 34; the lower end of the batch rectification tower 1 is fixedly installed with internally connected reboiler 2, and the heat source inlet of reboiler 2 A heat source inlet pipe 3 is fixedly installed on the top, a heat source outlet pipe 4 is fixedly installed on the heat source outlet of the reboiler 2, a feed pipeline 6 is fixedly installed on the upper feed port of the raw material tank 5, and the lower discharge port of the raw material tank 5 is connected to the A feeding pipeline 7 is fixedly installed between the upper feed inlet of the reboiler 2, an...

Embodiment 2

[0014] Embodiment 2, as the optimization of embodiment 1, as required, the raw material tank 5 inner cavity between the upper feed port of raw material tank 5 and the lower discharge port of raw material tank 5 is provided with dividing plate, dividing plate divides raw material tank The inner cavity of 5 is divided into a sedimentation chamber and a liquid collection chamber, the sedimentation chamber corresponds to the feed inlet of the upper part of the raw material tank 5, the liquid collection chamber corresponds to the discharge port of the lower part of the raw material tank 5, and the sedimentation chamber and the liquid collection chamber connected to the top. The vinyl chloride high-boiler enters the precipitation chamber from the feed port on the upper part of the raw material tank 5, and is initially cooled in the precipitation chamber. The water in the cooled liquid is layered and drained away in the lower layer. The upper end overflows into the liquid collectio...

Embodiment 3

[0015] Embodiment 3, as attached figure 1 As shown, the method of using the vinyl chloride high-boiler rectification device described in embodiment 1 or embodiment 2 to carry out the rectification and separation of vinyl chloride high-boiler is carried out according to the following steps: the first step, from the vinyl chloride The vinyl chloride high boilers from the high boiler rectification tower are sent to the raw material tank 5 through the feed line 6, and then the material is sent to the reboiler 2 through the feed line 6, and the reboiler 2 and the batch rectification tower 1 In the second step, when the material is sent into the reboiler 2, the refrigerant is passed into the condenser 12 for circulation, and the reboiler 2 is passed into the heat source, and the dichloroethylene control valve 38 and the dichloroethylene are closed. Ethane control valve 39, trichloroethylene control valve 40, trichloroethane control valve 41 and transition product control valve 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com