Method for preparing amorphous nanometer rhodium palladium alloy and catalytic application thereof

An amorphous, nano-rhodium technology, applied in nanotechnology, nanotechnology, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as unsatisfactory selectivity, and achieve high selectivity and high yield , the effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

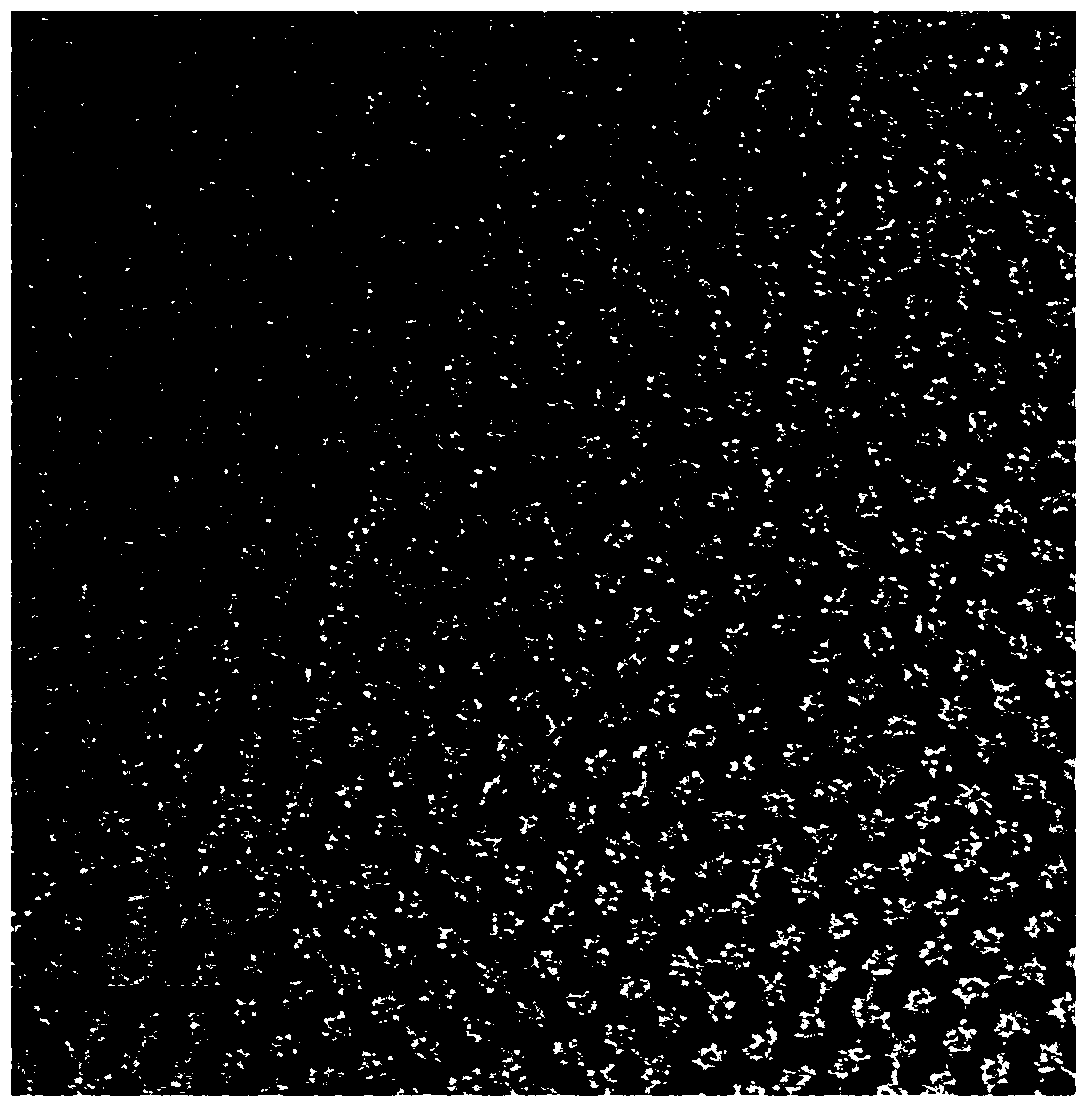

Embodiment 1

[0014] At 25°C, weigh 2mg of rhodium acetylacetonate and 1.5mg of palladium acetylacetonate, add them to 5ml of oleylamine, then add 60μL of tri-n-octylphosphine, put the above mixture into a 25ml beaker, and ultrasonicate for 20min at 25°C, then Stir magnetically at 25°C for 20 minutes; transfer the reaction solution to a 10ml autoclave, react at 200°C for 16 hours, and centrifuge the slurry after reaction for 3 times with a mixed solvent of ethanol and cyclohexane with a volume ratio of 10:1 at 70°C , the precipitate after centrifugation was dispersed in 4mL of cyclohexane to obtain an amorphous nano-rhodium-palladium alloy, the particle size of which was 5nm, and the dispersion was uniform.

[0015] The amorphous nano-rhodium-palladium alloy prepared above is used as a catalyst to catalyze the hydrogenation of phenylacetylene to prepare styrene. The reaction conditions are: the reaction temperature is 30 ° C, the reaction pressure is normal pressure, the catalyst amorphous n...

Embodiment 2

[0017] At 25°C, weigh 1.3mg of rhodium acetylacetonate and 2mg of palladium acetylacetonate, add them to 5ml of oleylamine, then add 60μL of tri-n-octylphosphine, put the above substances into a 25ml beaker, and ultrasonically for 20min at 25°C, then Stir magnetically at 25°C for 20 minutes; transfer the slurry to a 10ml reactor, and react at 200°C for 16 hours. The precipitate after centrifugation was dispersed in 4 mL of cyclohexane to obtain an amorphous nano-rhodium-palladium alloy, the particle size of which was 4.9 nm, and the dispersion was uniform.

[0018] The amorphous nano-rhodium-palladium alloy prepared above is used as a catalyst to catalyze the hydrogenation of phenylacetylene to prepare styrene. The reaction conditions are: the reaction temperature is 30 ° C, the reaction pressure is normal pressure, the catalyst amorphous nano-rhodium-palladium alloy and the reaction substrate phenylacetylene The molar ratio is 1:1200, and the reaction time is 2.5h.

[0019] ...

Embodiment 3

[0020] At 25°C, weigh 2.6 mg of rhodium acetylacetonate and 1 mg of palladium acetylacetonate, add them to 5 ml of oleylamine, and then add 100 μL of tri-n-octylphosphine, add the above substances into a 25 ml beaker, and ultrasonicate for 20 minutes at 25°C, then Stir magnetically at 25°C for 20 minutes; transfer the slurry to a 10ml reactor, and react at 200°C for 16h. After the reaction, the slurry is centrifuged and washed 3 times with a mixed solvent of ethanol and cyclohexane with a volume ratio of 10:1 at 65°C. The precipitate after centrifugation was dispersed in 4 mL of cyclohexane to obtain an amorphous nano-rhodium-palladium alloy, the particle size of which was 5.2 nm, and the dispersion was uniform.

[0021] The amorphous nano-rhodium-palladium alloy prepared above is used as a catalyst to catalyze the hydrogenation of phenylacetylene to prepare styrene. The reaction conditions are: the reaction temperature is 30 ° C, the reaction pressure is normal pressure, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com