A kind of method of synthesizing ethyl tertiary amyl ether

A technology of ethyl tert-amyl ether and ethanol, which is applied in the field of synthesizing ethyl tert-amyl ether, can solve the problems of reduced selectivity, accelerated decomposition of tert-amyl alcohol, poor stability, etc., and achieves long operation period, high conversion rate, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

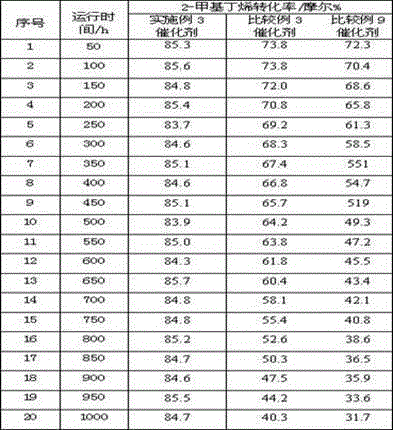

Examples

Embodiment 1~5

[0030] Preparation of magnesia and alumina (MgO-Al 2 o 3 ) Composite carrier supported cesium phosphotungstic acid salt catalyst:

[0031] After preparing mixed solutions of aluminum nitrate and magnesium nitrate with different concentrations, ammonia water was dropped into the above mixed solution, and a white precipitate was obtained under the conditions of co-precipitation temperature of 50° C. and pH value of 8.0 for 6 hours. After suction filtration, washing with deionized water, and drying at 100° C. for 10 hours. After the powder is extruded, it is calcined at 550°C for 10 hours to obtain magnesia and alumina (MgO-Al 2 o 3 ) Composite carrier.

[0032] The above (MgO-Al 2 o 3 ) composite carrier for 8 hours, dried at 100°C for 10 hours, calcined at 400°C for 6 hours, impregnated with phosphotungstic acid solution for 6 hours, dried at 100°C for 8 hours, and calcined at 450°C for 8 hours, Obtain cesium phosphotungstic acid salt / (MgO-Al 2 o 3 ) Composite supporte...

Embodiment 6~10

[0034] Preparation of titanium oxide and aluminum oxide (TiO 2 -Al 2 o 3 ) Composite carrier supported cesium phosphotungstic acid salt catalyst: replace magnesium nitrate in Example 1 with titanium tetrachloride, prepare mixed solutions of aluminum nitrate and titanium tetrachloride with different concentrations, and other conditions are the same as in Example 1. The compositions of the obtained supports and catalysts are shown in Table 1.

Embodiment 11~15

[0036] Preparation of zirconia and alumina (ZrO 2 -Al 2 o 3 ) Composite carrier loaded cesium phosphotungstic acid salt catalyst: Zirconium tetrachloride was used to replace magnesium nitrate in Example 1, and mixed solutions of aluminum nitrate and zirconium tetrachloride with different concentrations were prepared, and other conditions were the same as in Example 1. The compositions of the obtained supports and catalysts are shown in Table 1.

[0037] Table 1 Composition of aluminum-based composite oxide supports and catalysts

[0038] serial number Alumina / composite oxide carrier (mass%) Active component / catalyst (mass%) Example 1 80 20 Example 2 60 50 Example 3 30 30 Example 4 50 40 Example 5 40 35 Example 6 65 30 Example 7 35 40 Example 8 50 35 Example 9 45 30 Example 10 60 40 Example 11 30 50 Example 12 50 20 Example 13 70 35 Example 14 50 40 Example 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com