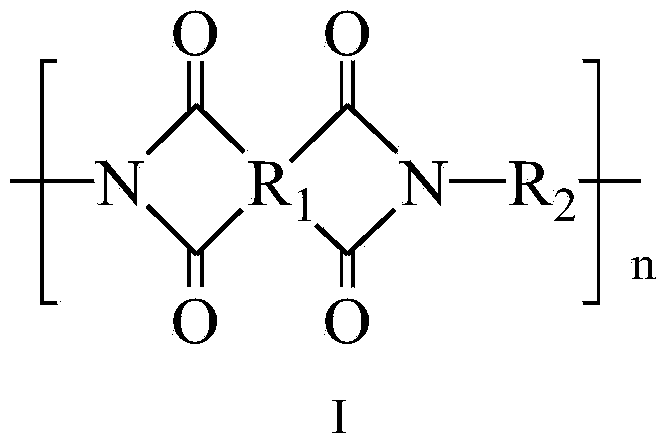

Colorless and transparent polyimide film and preparation method thereof

A technology of transparent polyimide and polyimide film, applied in the field of polymer materials, can solve problems such as reducing heat resistance, achieve high glass transition temperature and thermal decomposition temperature, reduce intermolecular interactions, improve Effects of Transparency and Heat Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

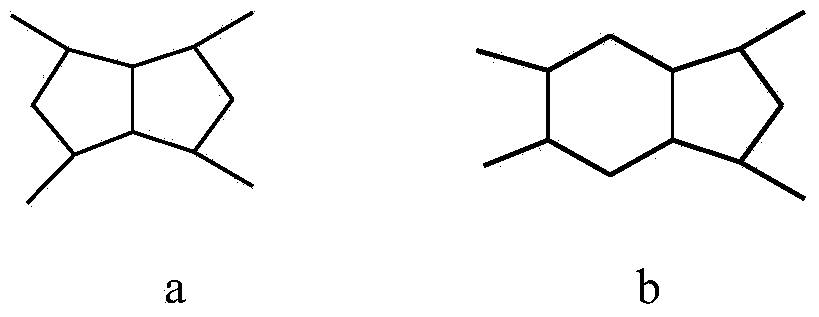

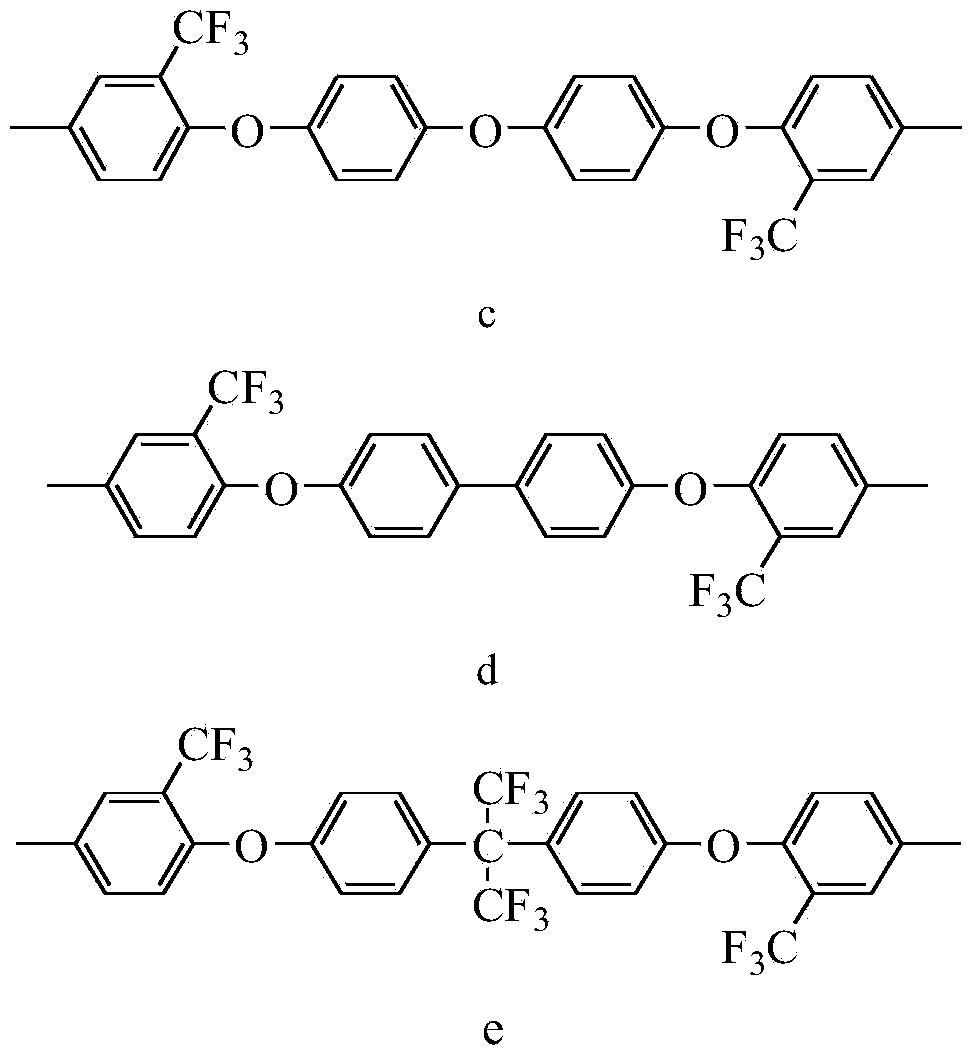

Embodiment 1

[0041] At room temperature, add 4.1634g (8mmol) 4,4'-bis(4-amino-2-trifluoromethylphenoxy)diphenyl ether into 37.30ml DMAc, nitrogen protection, mechanical stirring, until it is completely Dissolve and add 2.0016g (8mmol) bicyclo[3,3,0]octane-2,4,6,7-tetraacid dianhydride, continue to stir, and react for 24 hours under the protection of nitrogen to obtain a colorless, transparent, viscous, Polyamic acid solution (PAA) with a solid content of 15%. Place the obtained PAA solution in a vacuum oven with a relative vacuum of 0.08MPa to remove air bubbles at room temperature for 2 hours. After the air bubbles are removed, apply a film on a glass plate with a smooth surface, and the glass after coating The plate was first dried at 70°C for 2 hours, raised to 300°C at a rate of 5°C / min, and kept for 1 hour, and then naturally cooled to room temperature. The cooled glass plate was deionized in deionized water to obtain a colorless Transparent polyimide film, sampled by gel permeation ...

Embodiment 2

[0043] At room temperature, 5.2356g (8mmol) of 2,2'-bis[4-(4-amino-2-trifluoromethylphenoxy)phenyl]hexafluoropropane was added to 43.79ml of DMAc under nitrogen protection, Stir mechanically, until it is completely dissolved, add 2.0016g (8mmol) bicyclo[3,3,0]octane-2,4,6,7-tetraacid dianhydride, continue to stir, and react for 24 hours under nitrogen protection to obtain a colorless , Transparent, viscous, polyamic acid solution (PAA) with a solid content of 15%. Add 0.90 g of acetic anhydride and 1.33 g of pyridine to the obtained PAA solution, stir for 30 minutes under nitrogen protection, then increase the reaction temperature to 120 ° C, continue the reaction for 24 hours under nitrogen protection, and pour the resulting reaction solution into 5 times the volume of ethanol , precipitated, filtered, collected, washed with ethanol and dried to obtain polyimide resin (PI resin). Weigh 2g of polyimide resin and dissolve it in 12.10ml of DMAc to obtain a PI solution with a so...

Embodiment 3

[0045] At room temperature, 4.1634g (8mmol) of 4,4'-bis(4-amino-2-trifluoromethylphenoxy)diphenyl ether was added to 37.98ml of DMAc, nitrogen protection, mechanical stirring, until it was completely Dissolve and add 2.1138g (8mmol) of bicyclo[4,3,0]nonane-3,4,7,9-tetraacid dianhydride, continue to stir, and react for 24 hours under nitrogen protection to obtain a colorless, transparent, viscous, A polyamic acid solution (PAA) with a solid content of 15%, followed by the same operation in Example 1 to obtain a colorless and transparent polyimide film, and the weight average molecular weight detected by sampling gel permeation chromatography (GPC) was 3.5×10 4 . The main properties of the film are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com