Flexible conductive biopolymer material as well as preparation method and application thereof

A biopolymer, flexible and conductive technology, applied in the field of biomaterials, can solve problems such as poor ductility and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

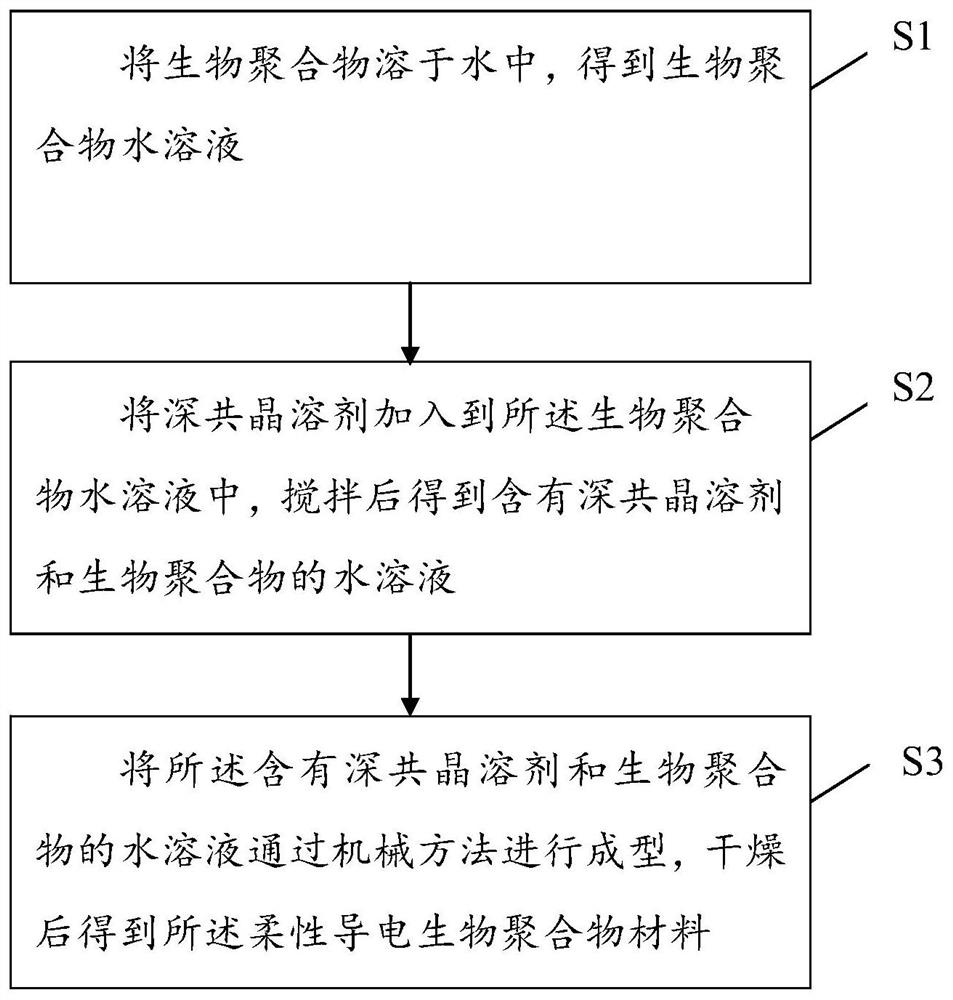

Method used

Image

Examples

Embodiment 1

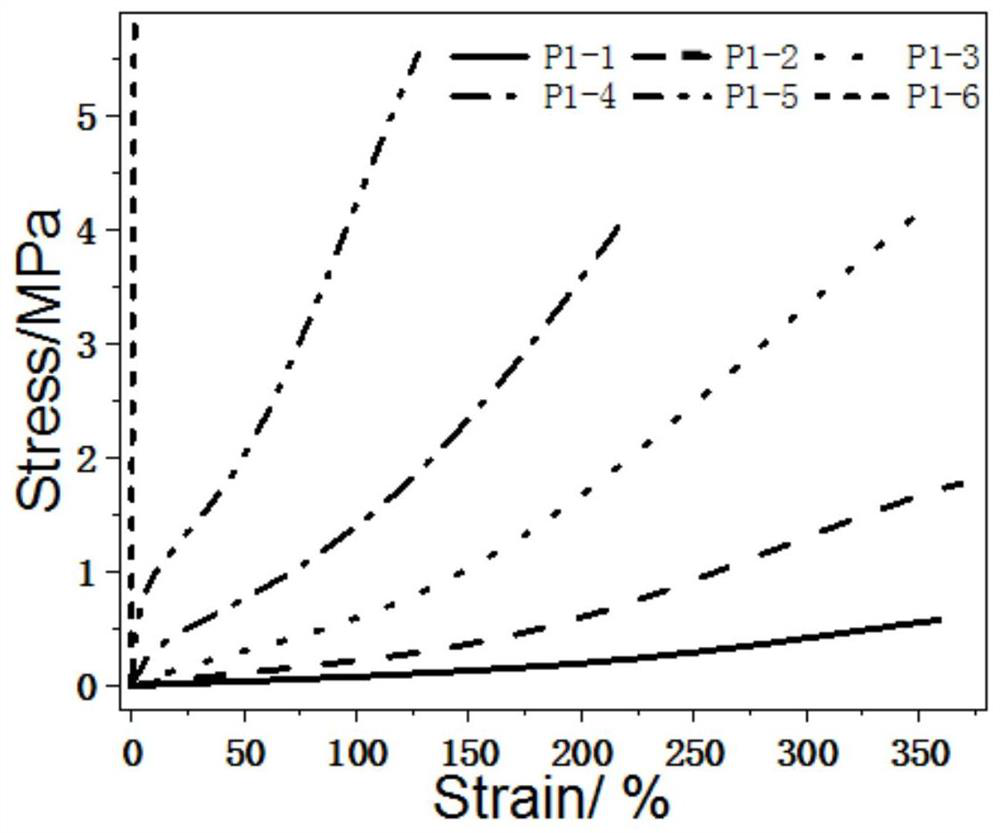

[0066] Configuration gelatin mass fraction is the gelatin aqueous solution of 15%, 2.6g choline chloride and 3.4g glycerin are mixed, stir until completely uniform, then it is joined in the 13.3g gelatin aqueous solution (the quality of gelatin is the same as that of choline chloride and glycerin) The ratio of mass to weight is 1:3), after stirring for 2 hours to mix evenly, pour it into a film mold, and dry it for 24 hours at a temperature of 40°C and a humidity of 20% to obtain a flexible film material, which is designated as P1-1.

[0067] Repeat the above steps, the difference is that the quality of the gelatin aqueous solution is 20g, 30g, 40g, 60g, 120g respectively, that is, the ratio of the quality of the gelatin to the mass sum of choline chloride and glycerin is 1:2, 3:4, 1 :1, 3:2, 3:1, and the obtained flexible film materials are recorded as P1-2, P1-3, P1-4, P1-5, P1-6 respectively.

[0068] The flexible thin film material prepared in embodiment 1 is carried out s...

Embodiment 2

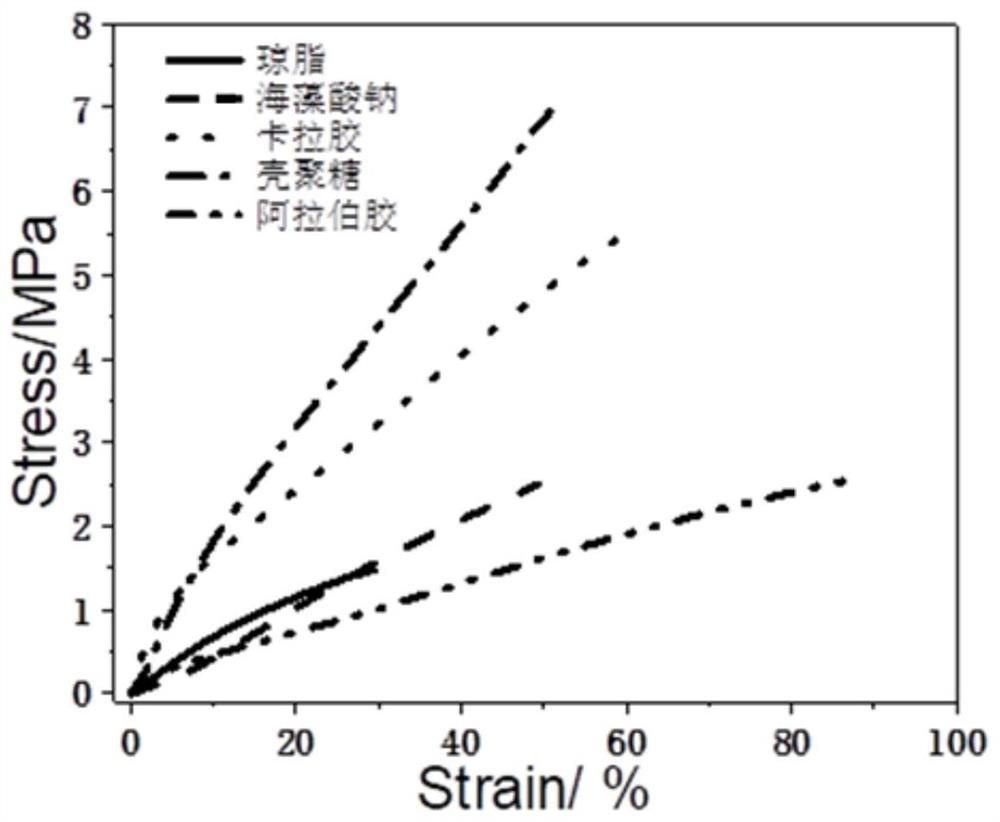

[0071] 2.6g choline chloride and 3.4g glycerol were mixed, stirred until completely uniform, then it was added to 20g agar aqueous solution (the mass fraction of agar was 2%), after stirring for 2 hours and mixed uniformly, poured in the film mould, It was dried for 24 hours under the conditions of temperature 40° C. and humidity 20%, to obtain a flexible film material.

[0072] Repeat above-mentioned steps 4 times, difference is that agar aqueous solution (massfraction of agar is 2%) is replaced by carrageenan aqueous solution (massfraction of carrageenan is 2%), sodium alginate aqueous solution (massfraction of sodium alginate is 2%) respectively. 2%), an aqueous solution of chitosan (the mass fraction of chitosan is 2%), an aqueous solution of gum arabic (the mass fraction of gum arabic is 2%).

[0073] The flexible thin film material prepared in embodiment 2 is carried out stress-strain test, the result is as follows image 3 shown by image 3 It can be seen that the ela...

Embodiment 3

[0075] Prepare a gelatin aqueous solution with a gelatin mass fraction of 15%, mix 3.23g of choline chloride and 2.77g of urea, stir until completely uniform, then add it to 20g of gelatin aqueous solution, stir for 2 hours and mix well, then pour into a film mold , dried for 24 hours at a temperature of 40° C. and a humidity of 20%, to obtain a flexible film material, which is designated as P2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com